Tensioning device, weaving machine, closing machine and method for tensioning a plurality of warp yarns

A technology of tensioning device and clamping device, applied in the directions of looms, textiles and auxiliary equipment for papermaking and weaving, etc., to achieve the effects of reliable piercing, uniform increase of warp stress, and improved separation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

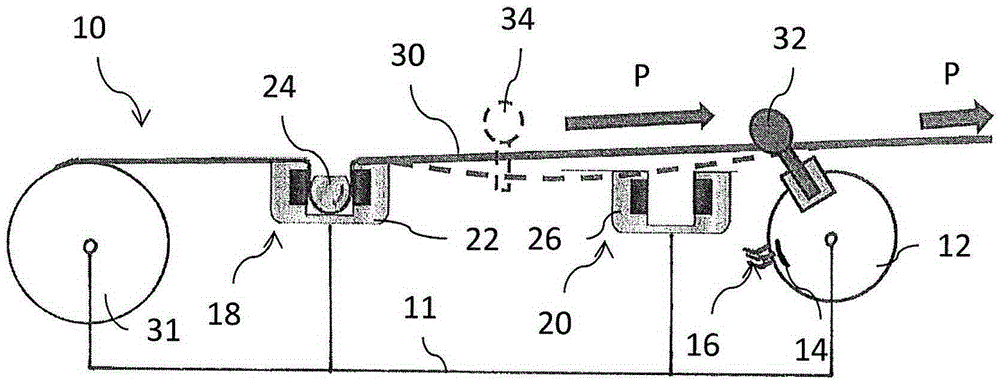

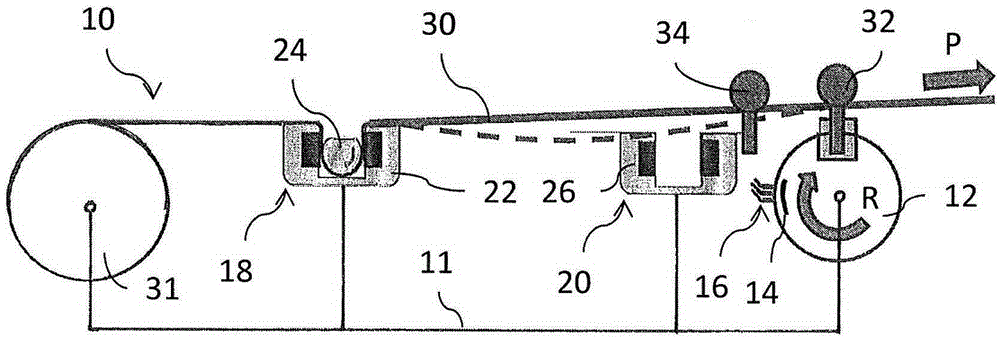

[0041] Figure 1a -f shows a schematic sequence of a method for tensioning warp threads, in particular flat plastic warp threads. A schematic view of a tensioning device 10 is shown, comprising a frame 11 and a tensioner 12, and which is perpendicular to the longitudinal direction of the tensioner 12 (longitudinal direction L, as in figure 2 and 4 as shown in ). The longitudinal direction of the tensioner 12 is substantially perpendicular to the extension of the warp threads 30 . The tensioner 12 is supported on the frame 11 and is designed in this example as a tensioning rod rotatably mounted relative to the frame 11 about an axis parallel to the longitudinal direction L. As shown in FIG. One or more joint strips 14 are attached to the surface of tensioner 12 . Each engagement strip 14 is provided with a plurality of rigid penetrating needles 16 . The term "rigid" is defined as a material property of the piercing needle which is sufficient for piercing or piercing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com