Raw material processing equipment for biomass energy source production

A kind of processing equipment and equipment technology, which is applied in the direction of grain processing, etc., can solve the problems affecting the concentration and conversion rate of substrate cellulose, and the impact of production costs, so as to reduce the residue of bone marrow and other sundries, reduce labor intensity, and reduce production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

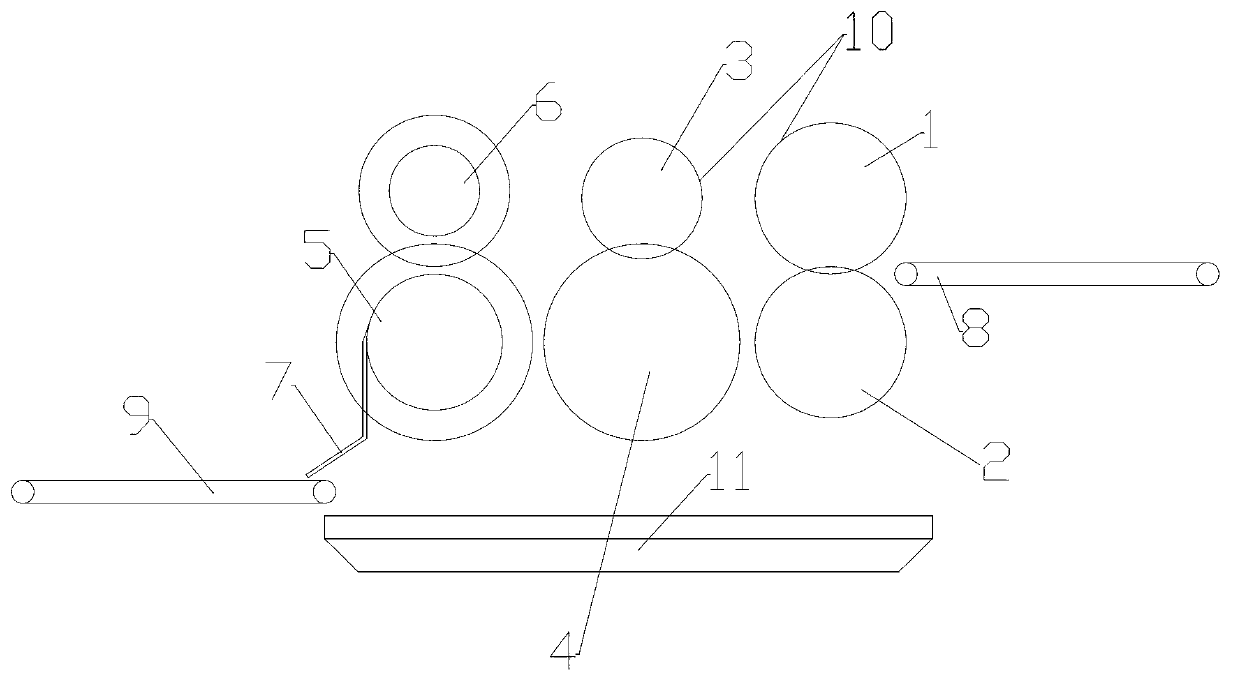

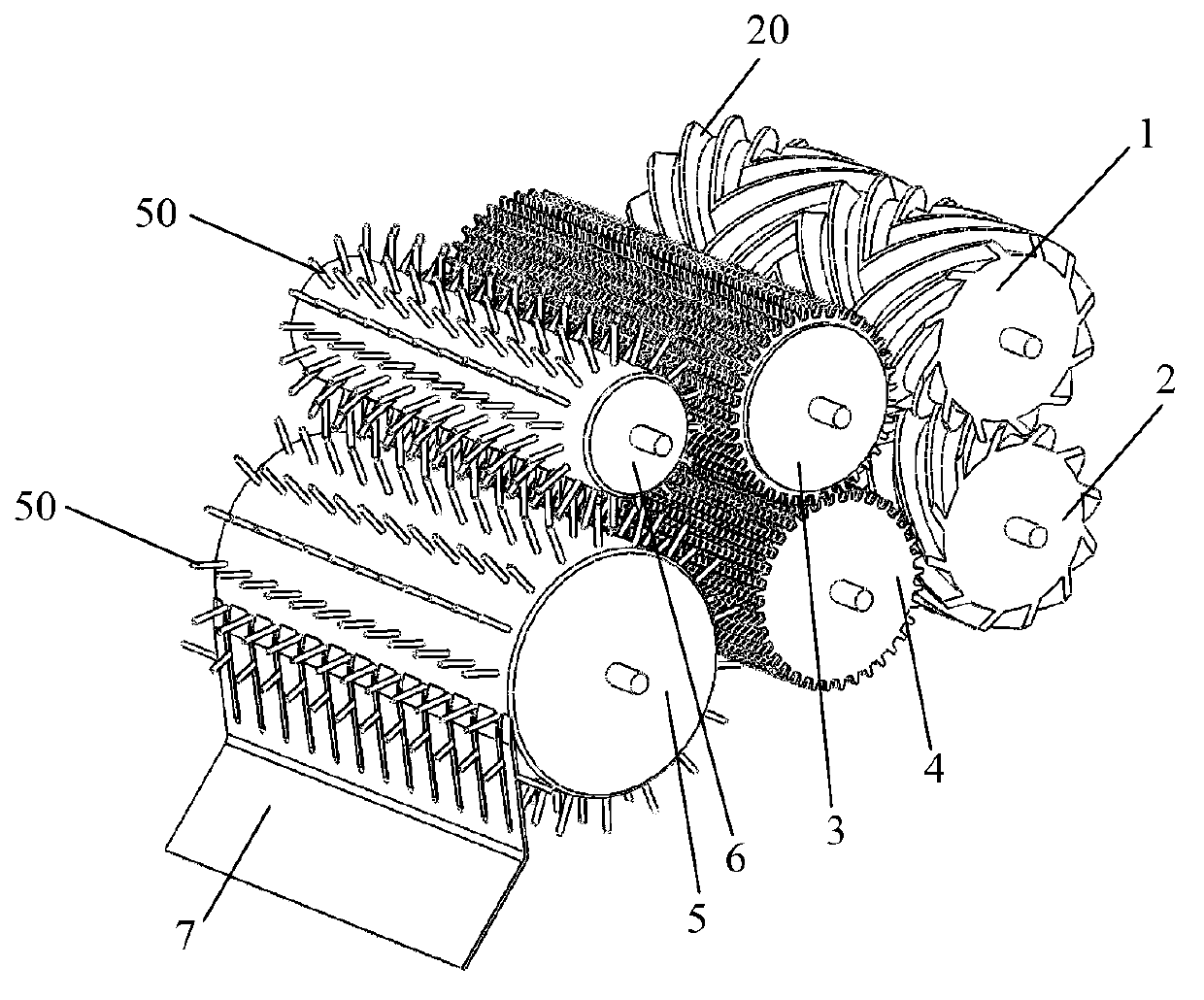

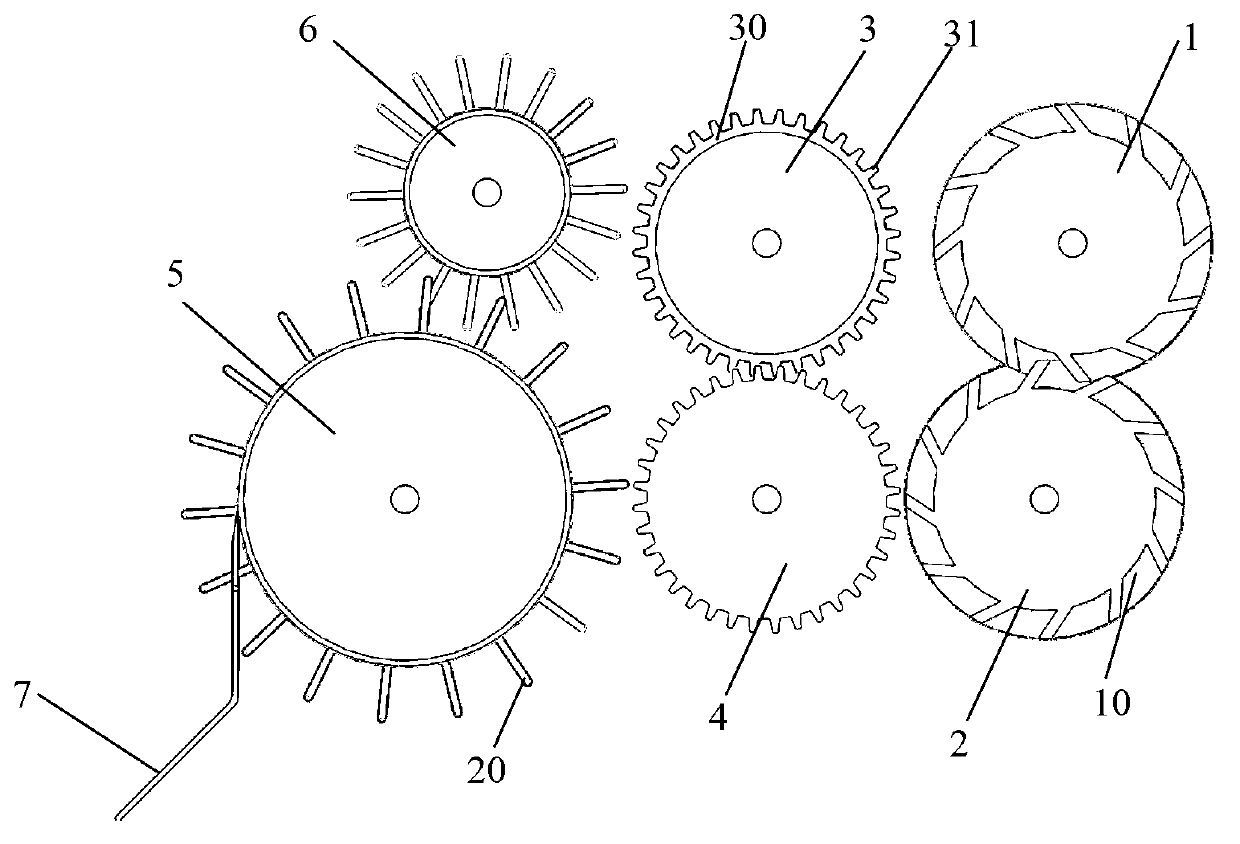

[0055] After extensive and in-depth research, the inventor of the present application has developed a new type of raw material processing equipment, which is suitable for fully separating the hemp bone and hemp skin of hemp crops such as kenaf. In the raw material processing equipment of the present invention, under the condition that the integrity of the hemp fiber is not required to be preserved, a new design has been made to the tooth pitch and tooth profile of the rolls, and the repeated rolling and pressing of various rolls can reduce the amount of hemp in the hemp as much as possible. The residue of hemp bone and other debris improves the purity of raw material of hemp skin, improves the separation efficiency of bone skin, reduces labor intensity and production cost, and can meet the needs of industrialization development. On this basis, the present invention has been accomplished.

[0056] Below in conjunction with specific embodiment, further illustrate the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com