Fat and oil composition for ingestion aid of food for persons with difficulty in swallowing and chewing, and food for persons with difficulty in swallowing and chewing

An oil composition, technology for chewing difficulty, applied in the fields of swallowing, aiding ingestion oil composition, and food for people with chewing difficulty, it can solve the problems of changing the cooking process, requiring labor, reducing calorie intake, etc., to achieve good cleaning and prevent loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

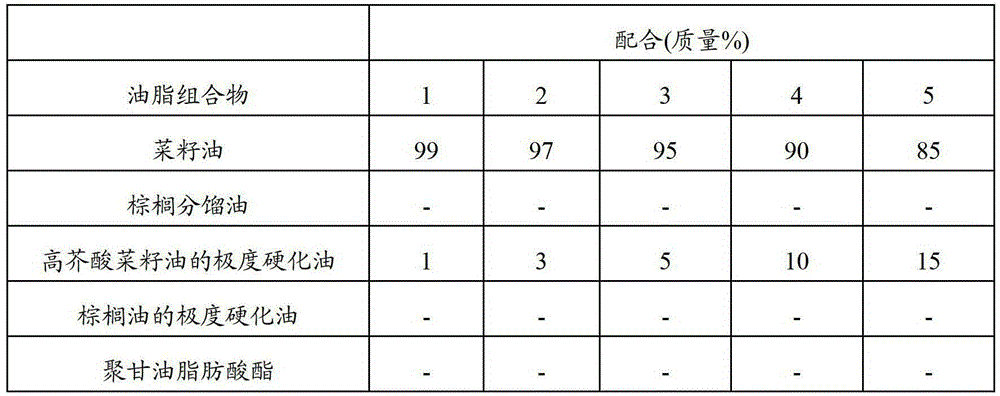

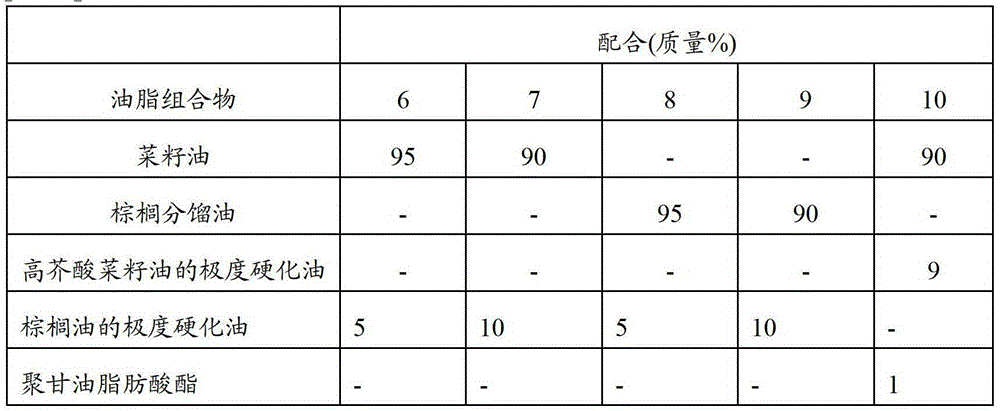

Embodiment 1~11、 comparative example 1~5

[0168]

[0169] In the above-mentioned compounding example 4, the oil and fat composition was produced by subjecting the composition which each added the emulsifier shown in Table 8 so that the amount may be 0.5 mass % to the quenching kneading process. In addition, the emulsifier used is as follows.

[0170] Emulsifier A: Sun Chemical Co., Ltd., brand name: Sunsoft O-30V

[0171] Emulsifier B: Sun Chemical Co., Ltd., brand name: Sunsoft Q-1810S

[0172] Emulsifier C: Sun Chemical Co., Ltd., brand name: Sunsoft Q-1710S

[0173] Emulsifier D: Sun Chemical Co., Ltd., brand name: Sunsoft Q-17B

[0174] Emulsifier E: Sun Chemical Co., Ltd., brand name: Sunsoft Q-18B

[0175] Emulsifier F: Sun Chemical Co., Ltd., brand name: Sunsoft A-173E

[0176] Emulsifier G: Riken Vitamin Co., Ltd., brand name: PoemeDO-100V

[0177] Emulsifier H: manufactured by Riken Vitamin Co., Ltd., brand name: Poeme J-0081HV

[0178] Emulsifier I: Sun Chemical Co., Ltd., brand name: Sunsoft A-181E

...

Embodiment 12~15、 comparative example 6~9

[0214]

[0215] In the above-mentioned compounding examples 3, 6, 8, and 9, oil and fat compositions were produced by subjecting the compositions to which the emulsifier G shown in Table 8 was added in an amount of 0.5% by mass to a quenching kneading treatment.

[0216] Specifically, 90% by mass of rapeseed oil and 10% by mass of extremely hardened oil of high erucic acid rapeseed oil were added to the container, and emulsifier G was added so that the amount was 0.5% by mass. After dissolving and mixing under heating, the container was placed in ice water and kneaded to obtain 50 g of an oil and fat composition subjected to quenching and kneading treatment. As a comparative control, except not adding an emulsifier, 50 g of an oil and fat composition subjected to quenching and kneading treatment was obtained in the same manner.

[0217]

[0218] The solubility of the emulsifier of each of the obtained oil and fat compositions, the taste, the cleansing properties during scr...

Embodiment 16、17、 comparative example 10

[0223] In the above-mentioned compounding example 4, SFC (%) was performed on the oil and fat composition produced by subjecting the composition to which the emulsifier G shown in Table 8 was added in an amount of 0.5 or 0.9% by mass to the quenching kneading treatment. Determination. As a control, the SFC (%) of the oil and fat composition produced in the same manner was also evaluated except that the emulsifier G was not added. Specifically, in the above reference example, the measurement was performed in the same manner as in the case of the measurement of the compounding example 1 and the like before the rapid cooling kneading treatment.

[0224] The measurement results are shown in Table 11. As a result, the SFC of the oil-fat composition which added 0.5 or 0.9 mass % of emulsifiers was about the same as the SFC of the oil-fat composition which did not add an emulsifier. That is, it was confirmed that addition of an emulsifier does not substantially affect SFC.

[0225...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com