Electrical connector and electrical connector assembly

An electrical connector and connector technology, which is applied to the parts, connection, and fixed connection of the connection device, can solve the problems of solder material, flux spatter, productivity reduction, and increase the emission of electromagnetic wave noise, and increase the number of manufacturing processes. , No damage to productivity, good electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

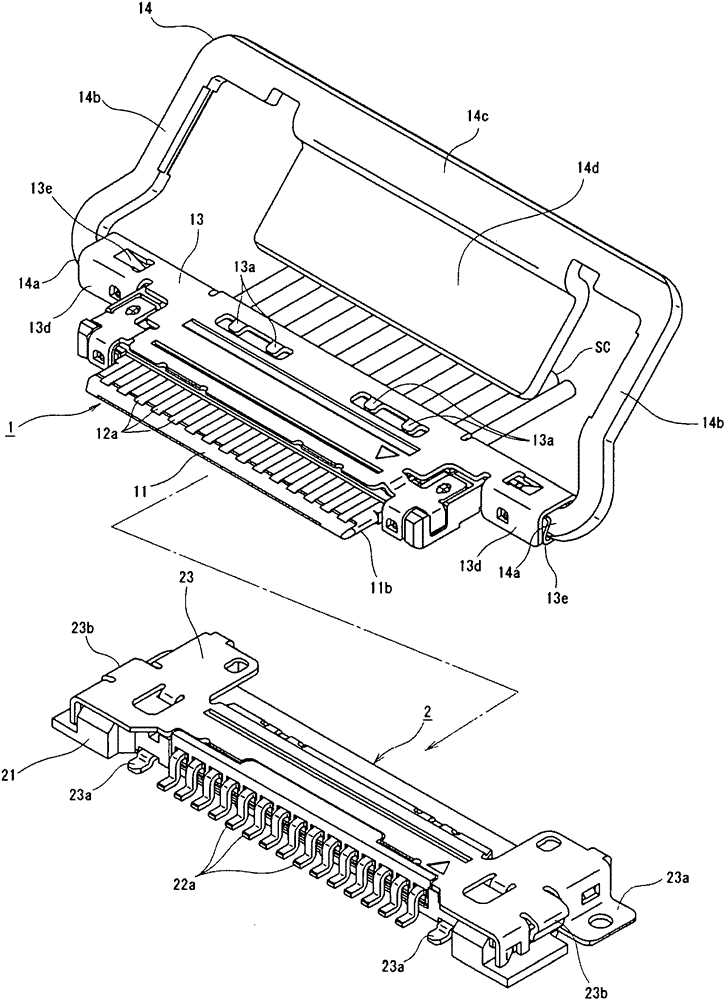

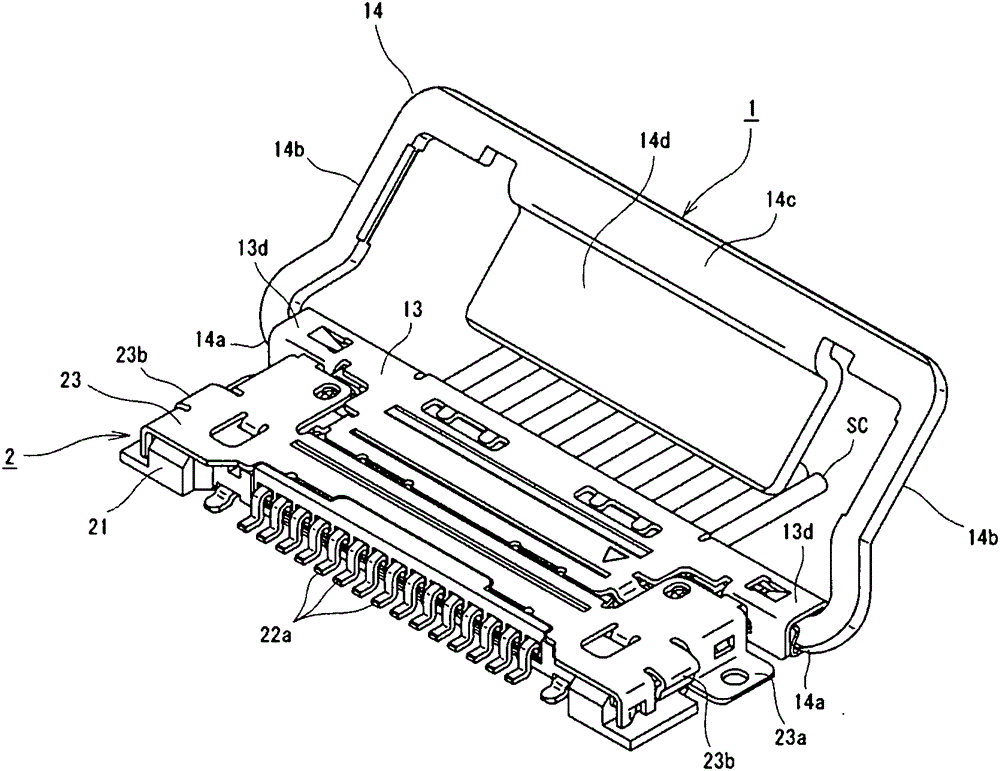

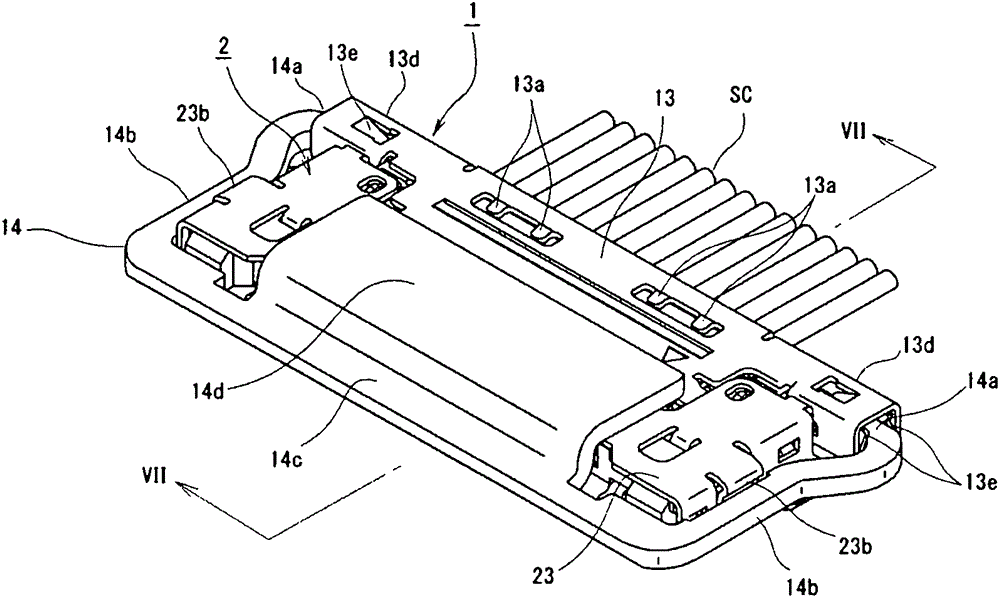

[0032] Embodiments in which the present invention is applied to an electrical connector for connecting a plurality of coaxial cables to the side of a printed wiring board will be described in detail below with reference to the drawings.

[0033] (Outline of the overall structure of the electrical connector assembly)

[0034] first, Figure 1 to Figure 7 The shown electrical connector assembly according to the first embodiment of the present invention is composed of a plug connector 1 to which a terminal portion of a coaxial cable SC is connected, and a receptacle connector mounted on a main printed wiring board B. 2 horizontal fitting type electrical connectors, as the first connector plug connector 1 relative to the mating object, that is, as the second connector receptacle connector 2 is arranged in the substantially horizontal direction, from this state to connect the above-mentioned plug device 1 moves closely along the surface of the main printed wiring board B, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com