High pressure cross-linked polyethylene insulated power cable

A cross-linked polyethylene and power cable technology, applied in the direction of power cables with shielding layer/conductive layer, etc., can solve the problems of single variety, many manufacturers, poor economic benefits, etc., and achieve excellent electrical performance, enhanced shielding effect, under pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

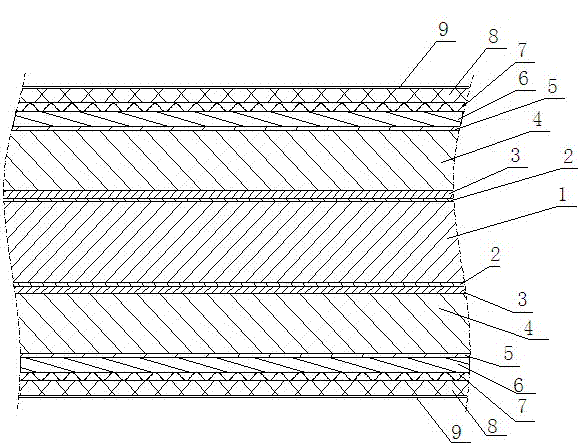

[0016] Such as figure 1 Shown is a schematic longitudinal section of the high-voltage cross-linked polyethylene insulated power cable of the present invention; it can be seen that the high-voltage cross-linked polyethylene insulated power cable includes: an insulated core and an insulated core wrapped outward in sequence Arranged semi-conductive buffer water blocking tape 6, corrugated copper sheath layer 7, high-density polyethylene outer sheath 8, graphite coating 9 is arranged on the outermost layer. In one embodiment, except for the corrugated copper sheath layer 7 , the cross-sections of the other layers are all concentric circles.

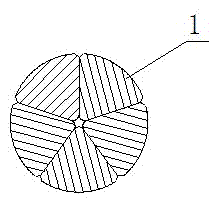

[0017] Wherein, the insulated wire core includes a conductor 1 at the center, and a semi-conductive nylon tape 2 , a conductor shielding layer 3 , a cross-linked polyethylene insulating layer 4 and an insulating shielding layer 5 that are arranged in sequence outside the conductor 1 .

[0018] Among them, the conductor adopts a compact round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com