Device for testing heat exchange performance of solar thermal collector interpolated with nanometer fluid heat pipe

A solar collector and nanofluid technology, applied in the direction of thermal development of materials, can solve the problems of internal material damage, prone to aging, poor performance, etc., and achieve the effects of low cost, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

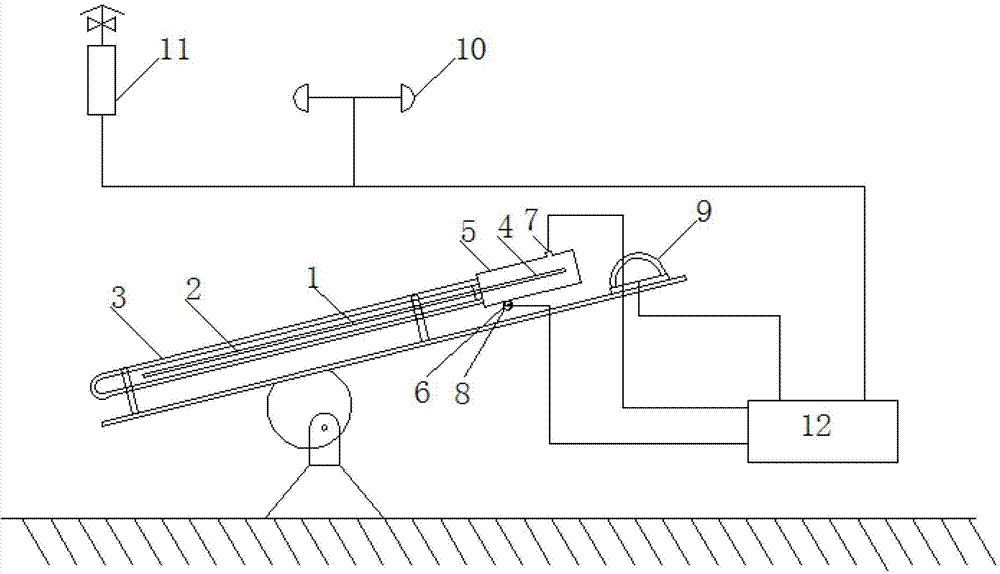

[0015] See figure 1 , The present invention includes a vacuum heat pipe 1, a glass vacuum tube 3, a heat exchanger 5, a solar radiation meter 9, a wind speed sensor 10, and an environmental thermometer 11. The vacuum heat pipe 1 is divided into an evaporation section 2 and a condensation section 4. The vacuum heat pipe 1 The evaporation section 2 of the vacuum heat pipe is inserted into the glass vacuum tube 3. The condensation section 4 of the vacuum heat pipe 1 is connected to the heat exchanger 5. The water tank 13 continuously supplies cold water to the condensation section 4 of the vacuum heat pipe 1 at the inlet 6, the outlet 7 of the heat exchanger 5. A thermocouple 8 is arranged at each location, and the output ends of the thermocouple 8, the solar radiation meter 9, the wind speed sensor 10, and the environmental thermometer 11 are connected to the data recorder 12.

[0016] The vacuum heat pipe 1 contains different working fluids such as water or nanofluid, and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com