Smart ball valve

A smart ball valve and smart ball technology, applied in the field of pressure valves, can solve problems such as valve failure, and achieve the effects of energy saving, simple operation, and extended valve life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

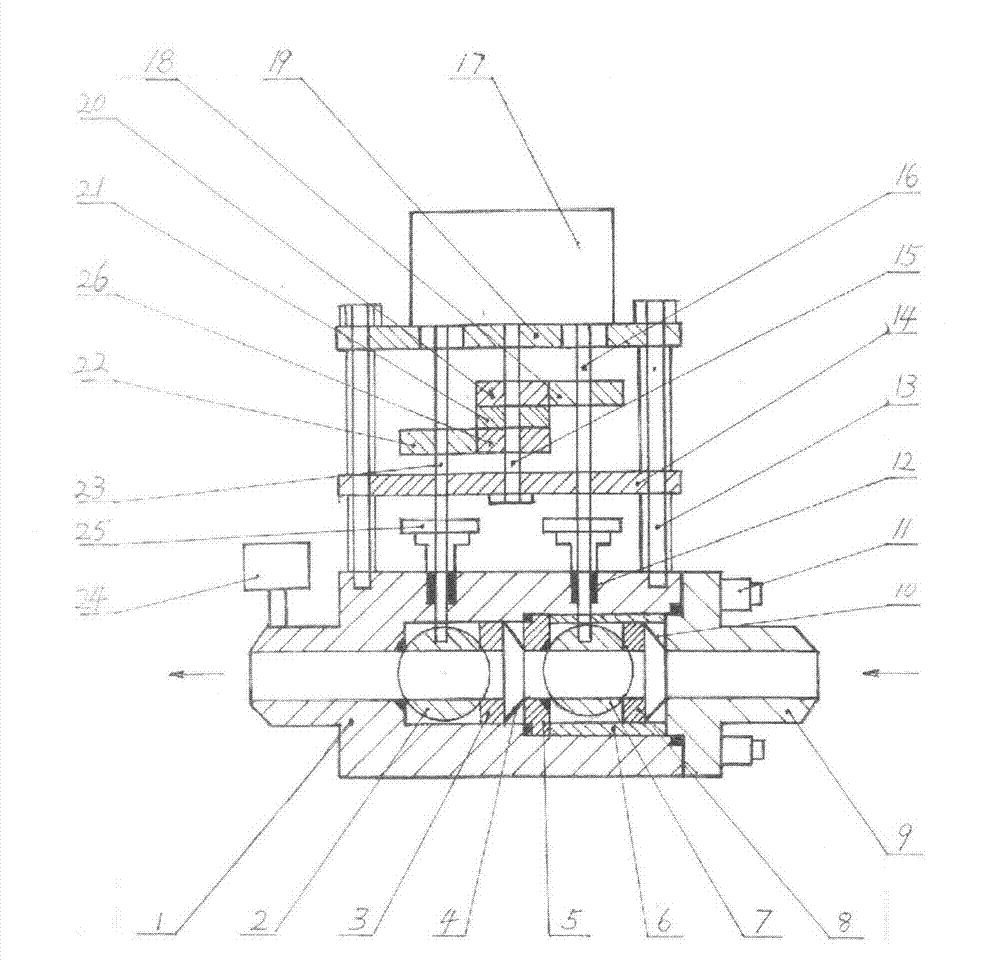

[0022] 1. The present invention will be further explained below in conjunction with the drawings, and the embodiments of the present invention will be made.

[0023] 2. Among them figure 1 An example is given with a sealing surface made of cemented carbide and ceramics. The smart ball valve includes a valve body, a leak detector and a bracket respectively connected to the valve body, and the transmission device mounted on the bracket passes The two driving wheels on the main shaft connected to it are connected to the two driven gears on the two valve stems connected with the two independent spheres installed in the valve body. A two-way clutch is installed between the two driving gears. , A sealing sphere in the valve body and a valve seat on the valve body form a sealing unit. A sealing sphere in the valve body and a movable valve seat installed in the valve body and fixed by a gasket, an adapter sleeve and a side valve body form a second unit. The two spheres are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com