Regulating valve of axial flow sleeve

A sleeve regulating valve, axial flow technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of assembly and maintenance difficulty, graphite column wear, low safety, etc., to improve the maximum flow capacity, improve the internal Organizational structure, the effect of expanding the adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

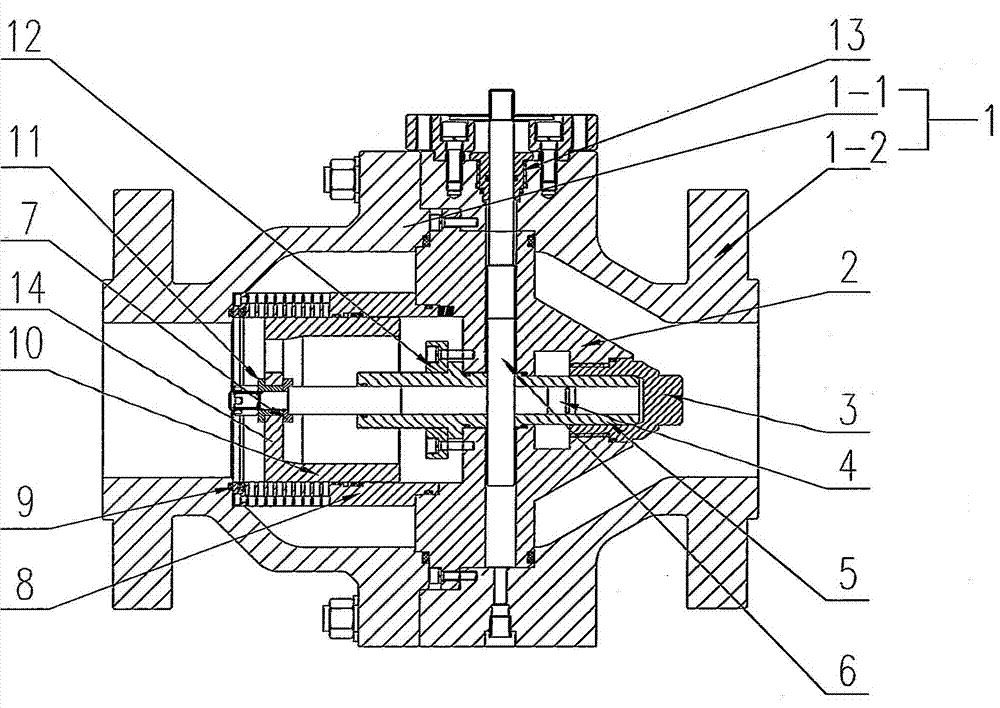

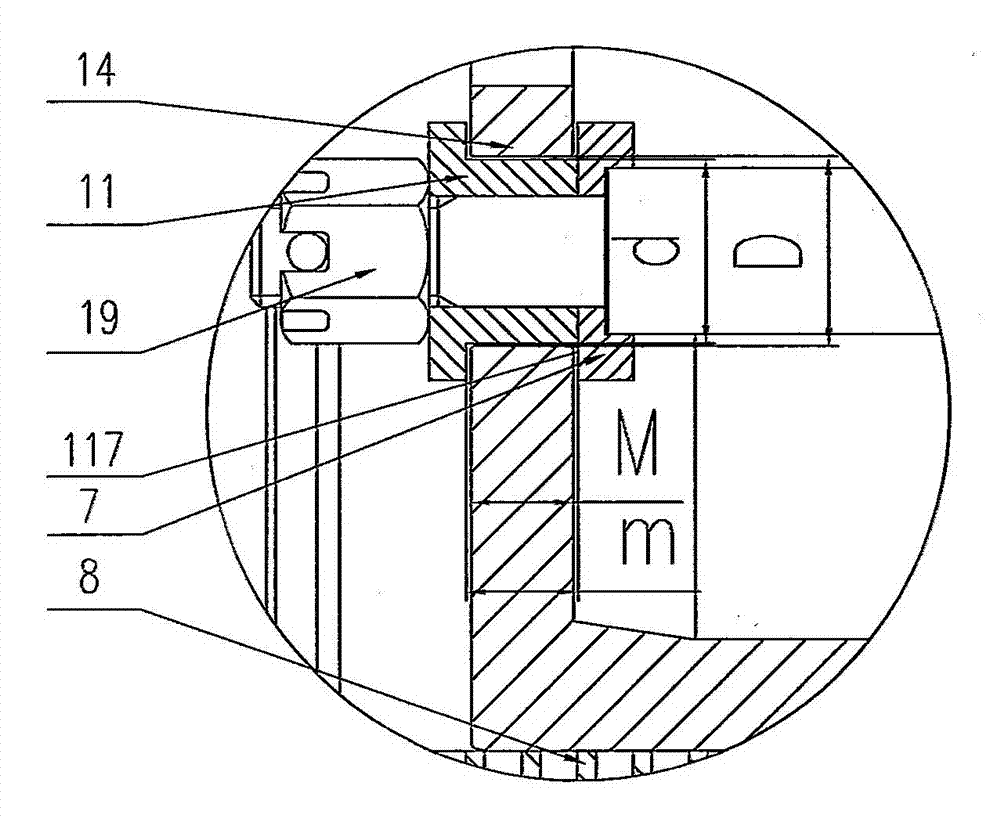

[0025] Such as figure 1 , 3 , 4, an axial flow sleeve regulating valve, including a split valve body 1, a valve core 2, a guide sleeve 5, a valve cage 8, a valve seat 9, a valve cylinder 10 and a transmission valve stem 4 and a transmission valve that can be The rod 4 moves axially in the guide sleeve 5 to drive the valve rod 6, the valve core 2 is installed in the split valve body 1, and one end of the driving valve rod 4 can be axially moved in the guide sleeve 5, and the guide sleeve 5 Inserted in the valve core 2, one end of the driving valve stem 6 passes through the split valve body 1, and the other end is inserted into the valve core 2 to be movably connected with the driving valve stem 4, and the valve cylinder 10 is movably inserted in the valve cage 8, There are several axial flow holes 8-1 on the valve cage 8, and the valve cage 8 is fixedly connected with the valve seat 9, the valve seat 9 is installed in the split valve body 1, and the other end of the transmissi...

Embodiment 2

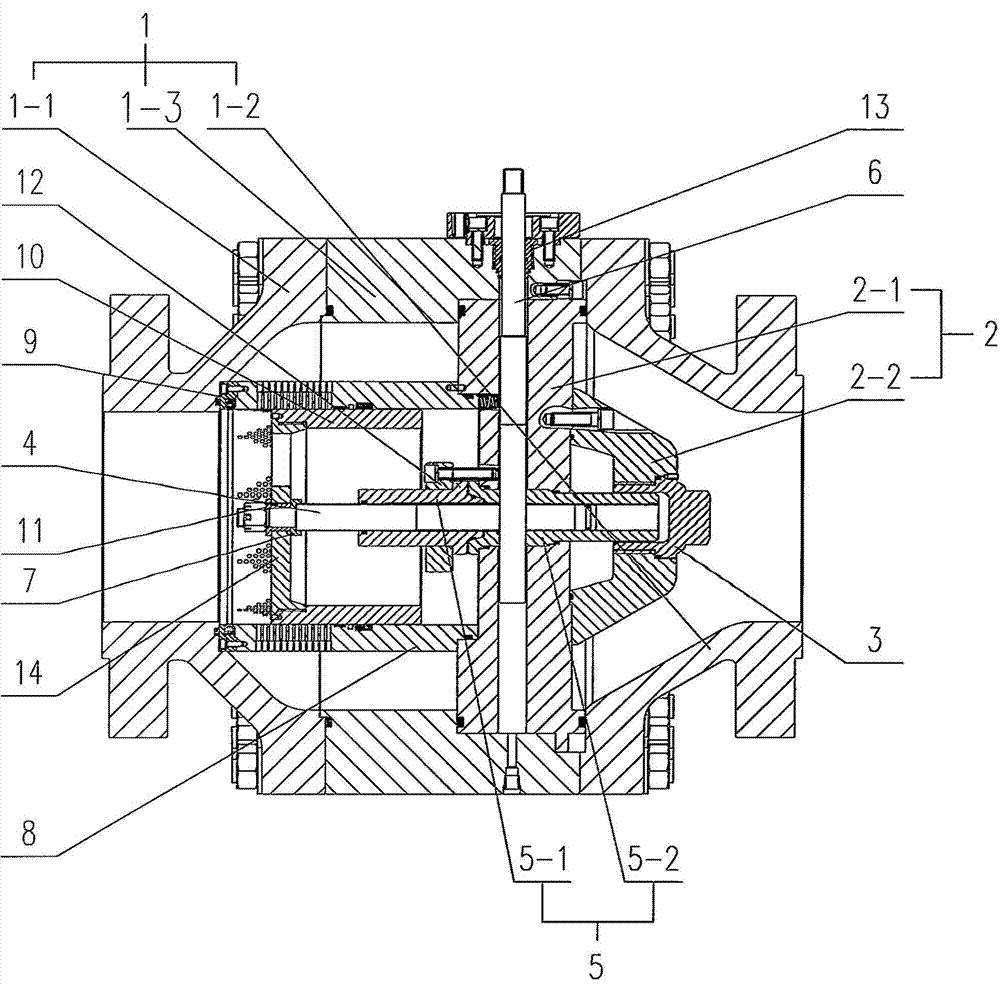

[0029] Such as figure 2 , 3 , 4, an axial flow sleeve regulating valve, including a split valve body 1, a valve core 2, a guide sleeve 5, a valve cage 8, a valve seat 9, a valve cylinder 10 and a transmission valve stem 4 and a transmission valve that can be The rod 4 moves axially in the guide sleeve 5 to drive the valve rod 6, the valve core 2 is installed in the split valve body 1, and one end of the driving valve rod 4 can be axially moved in the guide sleeve 5, and the guide sleeve 5 Inserted in the valve core 2, one end of the driving valve stem 6 passes through the split valve body 1, and the other end is inserted into the valve core 2 to be movably connected with the driving valve stem 4, and the valve cylinder 10 is movably inserted in the valve cage 8, There are several axial flow holes 8-1 on the valve cage 8, and the valve cage 8 is fixedly connected with the valve seat 9, the valve seat 9 is installed in the split valve body 1, and the other end of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com