Open caisson sealing bottom water drainage device and construction method

A technology of drainage device and construction method, applied in caisson, infrastructure engineering, construction and other directions, can solve the problems of high leakage plugging treatment cost, high investment cost, water leakage at the bottom of the sealing layer, etc., to improve engineering efficiency, low investment cost, installation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

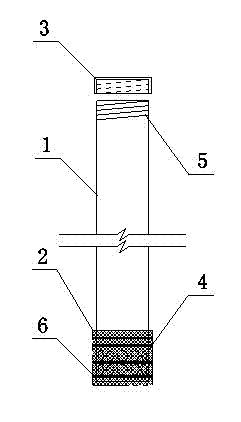

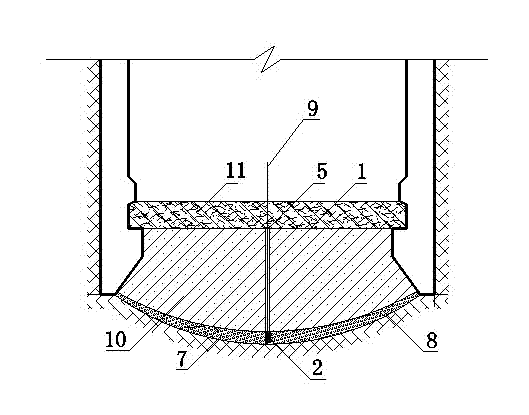

[0019] In the figure, the caisson bottom sealing drainage device of the present invention is mainly composed of a well pipe 1, a filter screen 2, a head cover 3, a water permeable hole 4, a wire tooth 5, an iron wire 6, a water permeable layer 7, a slurry layer 8, a water suction pipe 9, The back cover concrete 10 and the caisson floor 11 are composed.

[0020] The top of the well pipe 1 is connected with a head cover 3, the lower pipe wall is evenly provided with water permeable holes 4, and the bottom end of the well pipe 1 and the lower part of the pipe wall with the water permeable holes 4 are provided with a filter screen 2. 2 is fixed to the lower part of the well pipe 1 through the iron wire 6 . The head cover 3 is connected with the well pipe 1 through the wire teeth 5 . The filter screen 2 is a three-layer dense mesh screen.

[0021] A construction method usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com