Production method of melt direct spinning high-modulus low-shrinkage polyester industrial filament

A high modulus, low shrinkage, melt direct spinning technology, applied in the field of chemical fiber product manufacturing, can solve the problems of energy consumption and high waste yarn rate, achieve the effects of shortening the reaction time, ensuring the color of the melt, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

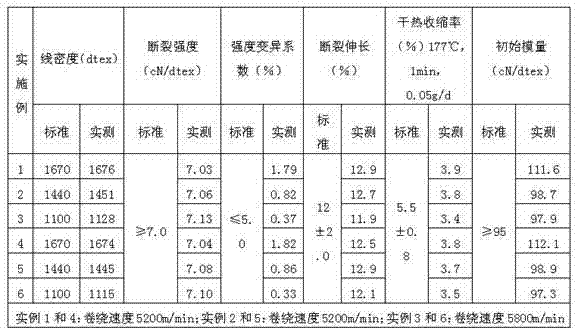

Embodiment 1

[0026] 1. The process parameters are as follows:

[0027] Equipment: LSP liquid phase polymerization equipment; spinning equipment; stretch winding equipment.

[0028] Product specifications: 1670dtex / 360f.

[0029] Raw materials: glossy polyester melt with a viscosity of 1.05dl / g after thickening; terminal carboxyl group-COOH≤25mol / t; diethylene glycol≤1.2%.

[0030] Liquid phase polymerization temperature: 278-285°C.

[0031] Spinning temperature: 290°C.

[0032] Slow cooling and heating temperature: 340°C.

[0033] Dosage pump supply: 867g / min.

[0034] Ring air cooling parameters

[0035] Wind pressure difference: 20Pa; Humidity: 65%; Wind temperature: 60°C.

[0036] Stretching conditions (two-stage stretching)

[0037] Primary stretch ratio: 1.3

[0038] Total stretch ratio: 1.97

[0039] Stretching roller speed m / min temperature ℃

[0040] GR1 2748

[0041] GR2 3572 98

[0042] GR3 5413 250

[0043] GR4 5413 255

[0044] GR5 5413 254

[0045] GR6 5310 130 ...

Embodiment 2

[0058] 1. The process parameters are as follows:

[0059] Equipment: LSP liquid phase polymerization equipment; spinning equipment; stretch winding equipment.

[0060] Product specification: 1440dtex / 360f

[0061] Raw materials: glossy polyester melt with a viscosity of 1.05dl / g; terminal carboxyl group-COOH≤25mol / t; diethylene glycol≤1.2%

[0062] Liquid phase polymerization temperature: 278~285℃

[0063] Spinning temperature: 290°C

[0064] Slow cooling and heating temperature: 340°C

[0065] Pump supply: 751g / min

[0066] Ring air cooling parameters

[0067] Wind pressure difference: 18Pa; Humidity: 65%; Wind temperature: 60℃

[0068] Stretching conditions (two-stage stretching)

[0069] Primary stretch ratio: 1.3

[0070] Total stretch ratio: 1.96

[0071] Stretching roller speed m / min temperature ℃

[0072] GR1 2780

[0073] GR2 3614 98

[0074] GR3 5449 250

[0075] GR4 5449 255

[0076] GR5 5449 254

[0077] GR6 5280 130

[0078] Relaxation rate: 3.21%

...

Embodiment 3

[0090] 1. The process parameters are as follows:

[0091] Equipment: LSP liquid phase polymerization equipment; spinning equipment; stretch winding equipment.

[0092] Specifications: 1110dtex / 240f

[0093] Raw materials: glossy polyester melt with a viscosity of 1.05dl / g; terminal carboxyl group-COOH≤25mol / t; diethylene glycol≤1.2%

[0094] Liquid phase polymerization temperature: 278-285°C

[0095] Spinning temperature: 290°C

[0096] Slow cooling and heating temperature: 340°C

[0097] Pump supply: 644g / min

[0098] Ring air cooling parameters

[0099] Wind pressure difference: 17Pa; Humidity: 65%; Wind temperature: 60℃

[0100] Stretching conditions (two-stage stretching)

[0101] Primary stretch ratio: 1.3

[0102] Total stretch ratio: 2.06

[0103] Stretching roller speed m / min temperature ℃

[0104] GR1 2935

[0105] GR2 3816 90

[0106] GR3 6046 240

[0107] GR4 6046 254

[0108] GR5 6046 254

[0109] GR6 5880 130

[0110] Relaxation rate: 2.84%

[011...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com