Metakaolin-based inorganic composite cementitious material and its toughening modifier

A toughening modifier and metakaolin technology, which is applied in the field of metakaolin-based inorganic composite cementitious materials and their toughening modifiers, can solve the problems of affecting the fiber toughening effect, high market price of carbon fiber, and high requirements for preparation conditions , to achieve the effect of compressive strength without side effects, low production cost and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw material weight ratio is:

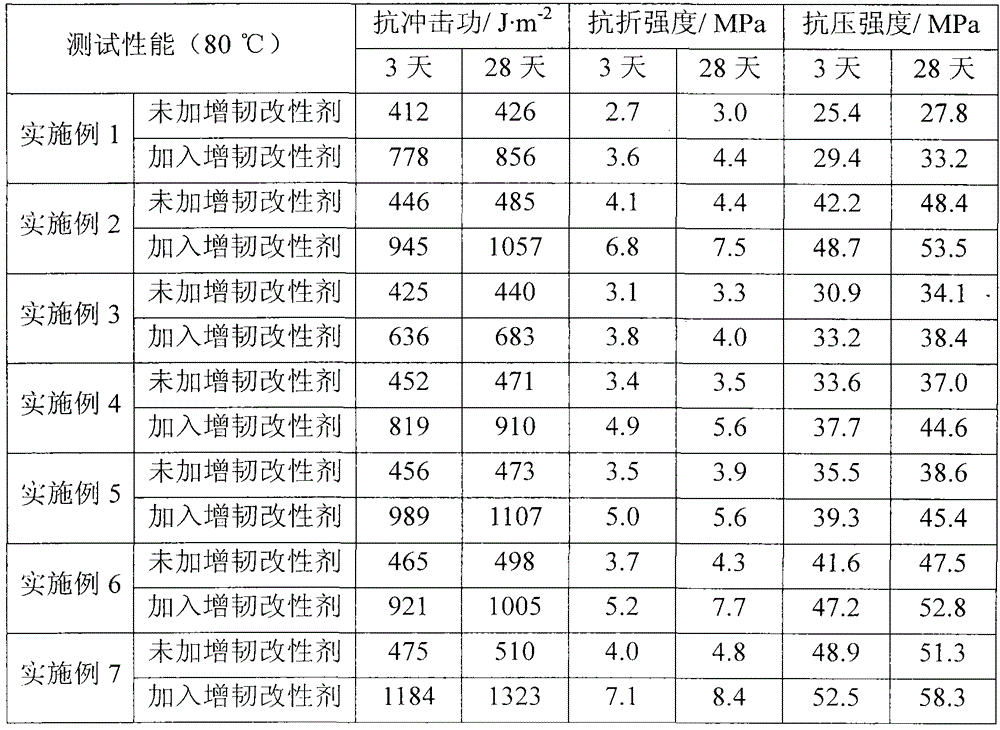

[0027] Metakaolin (100 mesh) 700g, slag (600 mesh) 300g, toughening modifier 10g, wherein in the toughening modifier 6.0g of medium-alkali glass fiber, 4.0g of hydroxyethyl cellulose, mixed with this ratio The performance of the prepared metakaolin-based inorganic composite cementitious material is tested, and the performance results of the metakaolin-based inorganic composite cementitious material prepared without toughening modifier are shown in Table 1.

Embodiment 2

[0029] Raw material weight ratio is:

[0030] 300g of metakaolin (400 mesh), 700g of slag (400 mesh), 12g of toughening modifier, wherein 9.6g of polypropylene fiber and 2.4g of carboxymethyl cellulose in the toughening modifier are prepared after mixing in this proportion Table 1 shows the performance of the metakaolin-based inorganic composite cementitious material tested and the properties of the metakaolin-based inorganic composite cementitious material prepared without toughening modifier.

Embodiment 3

[0032] Raw material weight ratio is:

[0033] Metakaolin (300 mesh) 700g, slag (200 mesh) 300g, toughening modifier 6g, wherein in the toughening modifier, polypropylene fiber 2.4g, medium alkali glass fiber 2.4g, hydroxyethyl cellulose 1.2g, Table 1 shows the performance of the metakaolin-based inorganic composite cementitious material prepared after mixing with this ratio and the performance of the metakaolin-based inorganic composite cementitious material prepared without toughening modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com