Automatically overturning machine

An automatic turning and turning arm technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of laborious handling, and achieve the effect of convenient operation, simple handling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

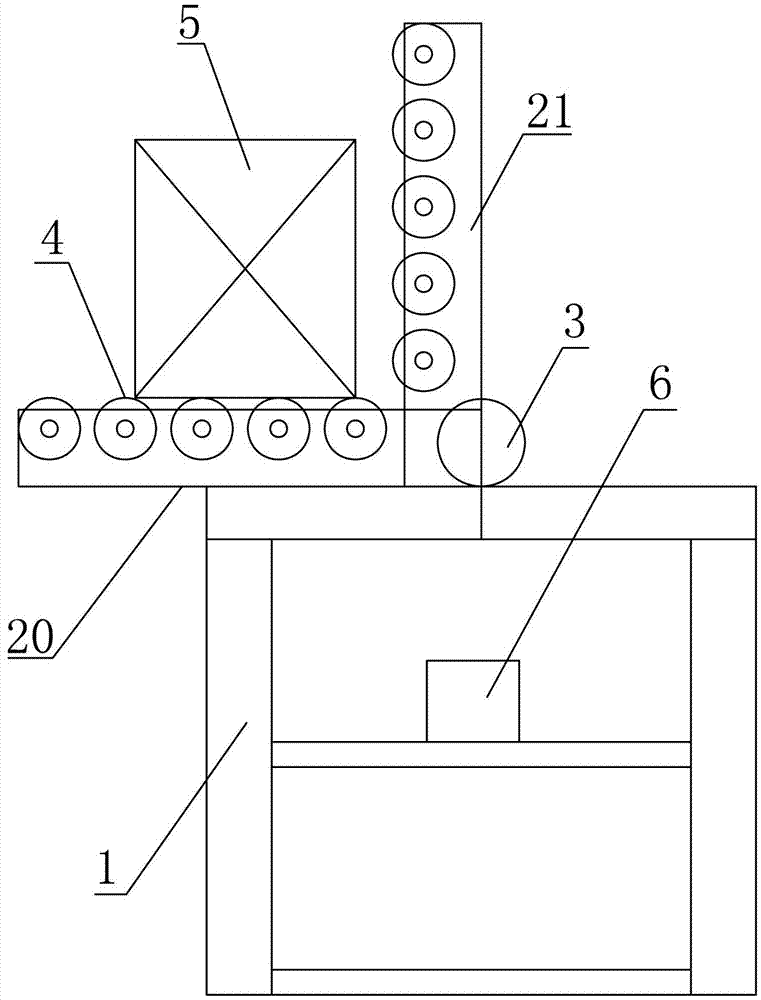

[0016] like figure 1 , 2 An automatic turning machine is shown, which includes a frame 1, a turning part arranged on the upper part of the frame 1, and a driving part that drives the turning part to turn over. Each component is described in detail as follows:

[0017] The overturning part includes a pair of overturning arms 20, 21 that can be overturned along the same rotating shaft 3, and the pair of overturning arms 20, 21 are arranged close to vertically. In this embodiment, the workpieces of the pair of overturning arms 20, 21 are arranged in an L shape. , the rotating shaft 3 is arranged at the joint of a pair of flipping arms 20, 21, and the surface of a pair of flipping arms 20, 21 is provided with several rollers 4, the axes of several rollers 4 are parallel, and the rollers 4 facilitate the rotation of the rotor / stator 5 transport.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com