Hopper bin wall vibrating air hammer

A technology of hopper bin and pneumatic hammer, which is applied in the direction of container, packaging, transportation and packaging, etc., can solve the problems that coal blocking cannot be fundamentally eliminated, the area of action of the air cannon is small, and the anti-blocking coal liner is loose, etc., to achieve The effect of simple structure, saving manpower and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

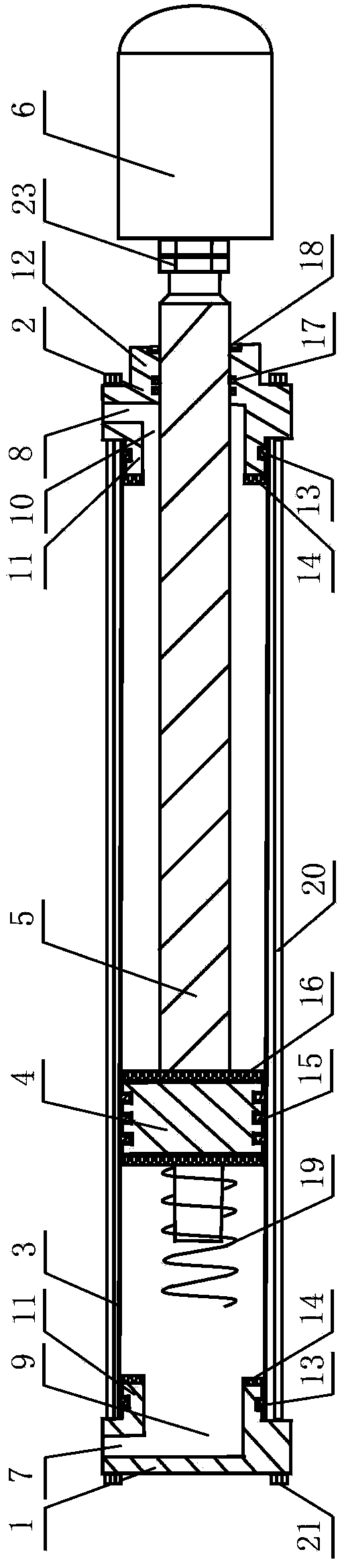

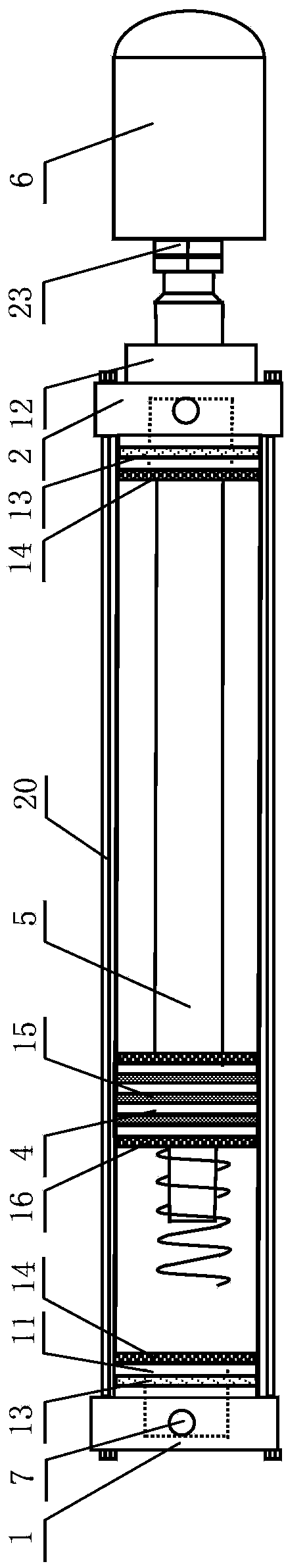

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] The present invention comprises left support 1, right support 2, cylinder body 3, piston 4, piston rod 5, hammer head 6 etc.

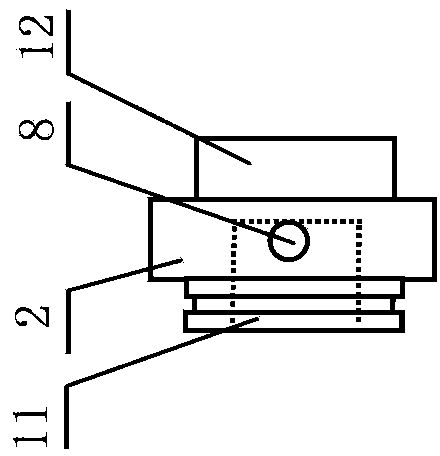

[0033] Such as figure 1 , 2 As shown, the left support 1 is provided with a left air intake hole 7, a left air intake channel 9 and a circular boss 11 with grooves, and the right support 2 is provided with a right air intake hole 8 and a right air intake channel. 10. A circular boss 11 and an end platform 12 with grooves. The outer ring of the circular boss 11 is provided with a male thread, and the two ends of the cylinder body 3 are provided with a female thread, and the two are screwed together. On the circular bosses 11 of the left support 1 and the right support 2, grooves are provided for installing the sealing ring I13, and impact-resistant rubber pads I14 are arranged on the end faces of the circular bosses. A seal ring III ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com