High-efficiency tablet press with feed chute

A technology of feeding trough and tablet press, which is applied to material molding presses, presses, manufacturing tools, etc., can solve the problems of unsatisfactory molding effect, uneven force on medicinal powder, and difficulty in taking out tablets, etc., so as to achieve the molding effect. Good, uniform force, the effect of preventing the powder from spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

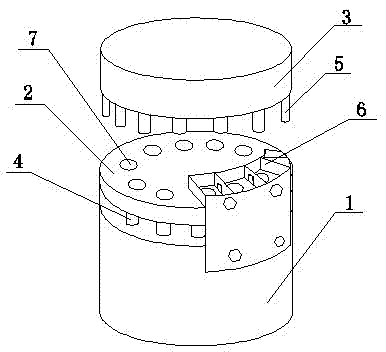

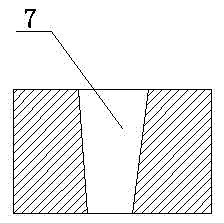

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a support platform 1, a round platform 3 and a disk 2 arranged on the support platform 1. The disk 2 is linked with a stepping motor arranged in the support platform 1, and the disk 2 is provided with a conical molding Hole 7.

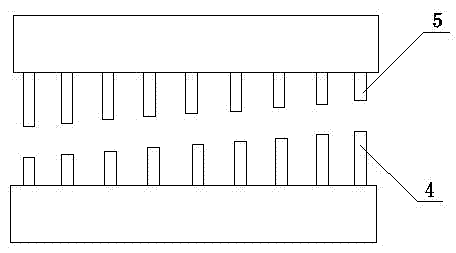

[0020] The lower end face of the round table 3 of this embodiment is provided with a cylindrical upper punch 5, the size of the upper punch 5 matches the size of the forming hole 7, there are at least four upper punches 5, and the upper punch 5 is positioned on the round table. 3 in a circular distribution, and the adjacent upper punches 5 are equally spaced.

[0021] The support table 1 of the present embodiment is provided with a lower punch 4, which corresponds to the forming hole 7 one by one, and the size of the lower punch 4 matches the forming hole 7, and the support table 1 is provided with a bolt fixed The arc-shaped feeding trough 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com