Locking and safety protection mechanism of slush molding machine die and powder box

A technology of safety protection and slush molding machine, applied in the direction of coating, etc., can solve the problems of locking pins and safety pins that cannot be opened, poor wear resistance, and easy entry of powder, so as to reduce the frequency of replacement and improve wear resistance , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

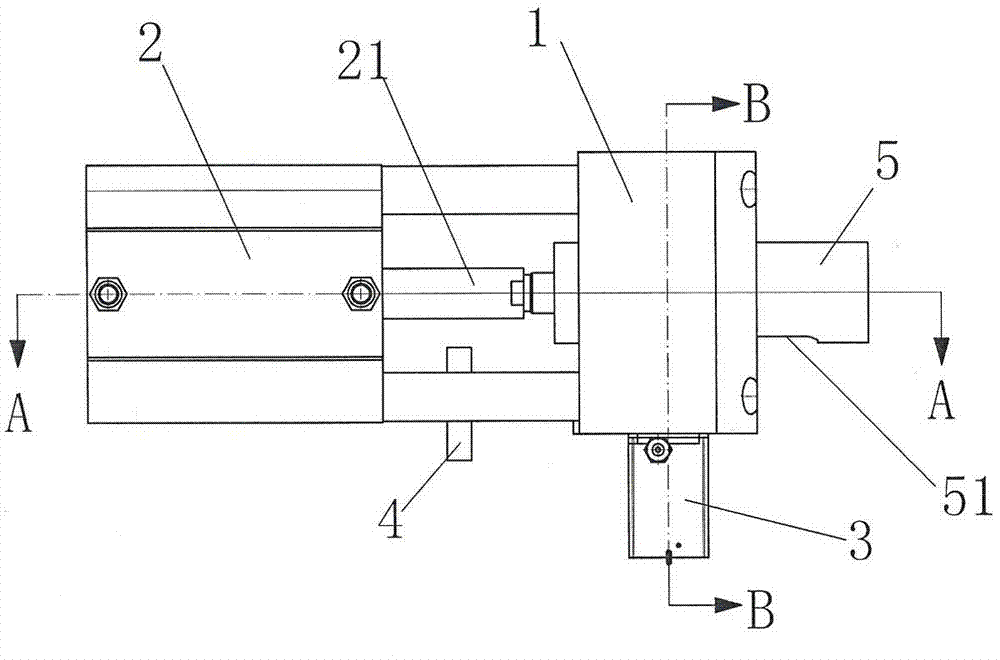

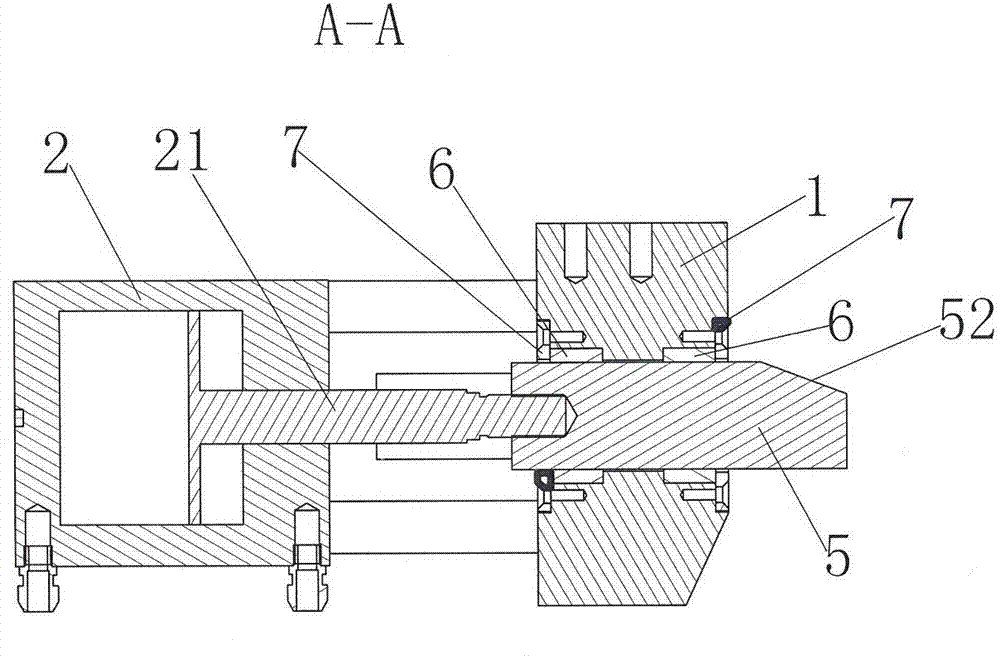

[0013] see figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment is composed of a cylinder block 1, a locking cylinder 2, a safety cylinder 3 and a detection proximity switch 4. Both the locking cylinder 2 and the safety cylinder 3 are installed on the cylinder block 1, and the locking cylinder 2 is located on the cylinder block 1, the safety cylinder 3 is located on the side of the cylinder block 1, the cylinder block 1 is provided with a locking pin 5, and a pin sleeve 6 is set between the locking pin 5 and the cylinder block 1, and the pin sleeve 6 is two , the two pin sleeves 6 are located on the front and rear sides of the cylinder block 1, and the two pin sleeves 6 are respectively fixed on the cylinder block 1 with a gland 7. The pin sleeves 6 are copper sleeves, and the tail of the locking pin 5 is locked The piston rod 21 of the cylinder 2 is connected together. In this embodiment, the tail of the locking pin 5 is screwed together with the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com