Anti-explosion combination wrench with replaceable bayonets

A dual-purpose wrench and bayonet technology, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve problems such as inconvenience in carrying, and achieve the effects of convenient carrying, reduced number of tools, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

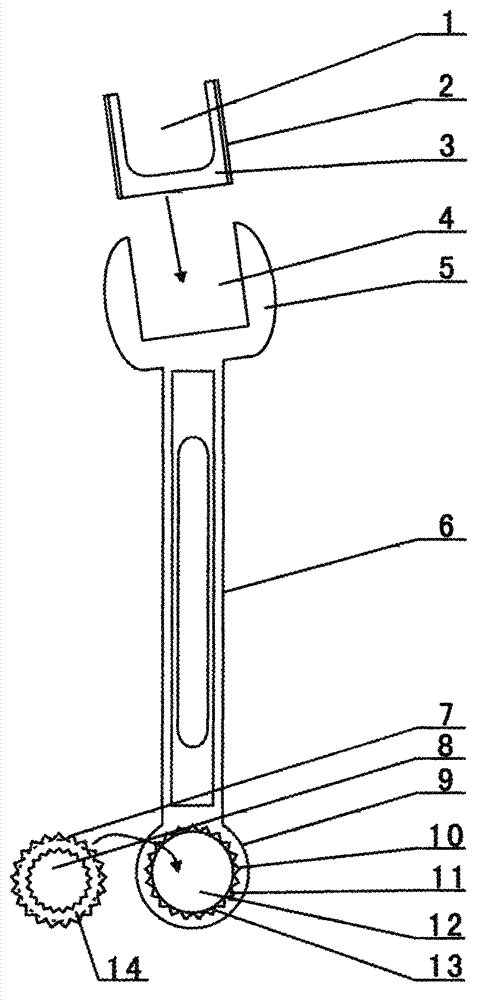

[0020] combined with Figure 1-14 The explosion-proof double-purpose wrench with replaceable bayonet socket includes a handle 6, an open end 5, a "U"-shaped connector 3, a plum blossom end 9 and an embedded kit 14, and the open end 5 and the plum blossom end 9 are set respectively. At both ends of the handle 6, the open end 5 has a socket 4, and grooves 15 are respectively arranged on the two side walls of the socket 4, and rubber layers 16 are respectively arranged in the grooves 15 on both sides of the socket 4, in a "U" shape. The protruding strips 2 provided on the outer walls on both sides of the connector 3 are plugged into the groove 15 of the socket 4; Figures 11-14 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com