A fine-grained lightweight powder blending device

A technology of fine particle size and powder, which is applied in the field of fine particle size and light weight powder blending device, can solve the problems of easy agglomeration of powder, achieve the effect of eliminating powder agglomeration, eliminating dust pollution, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

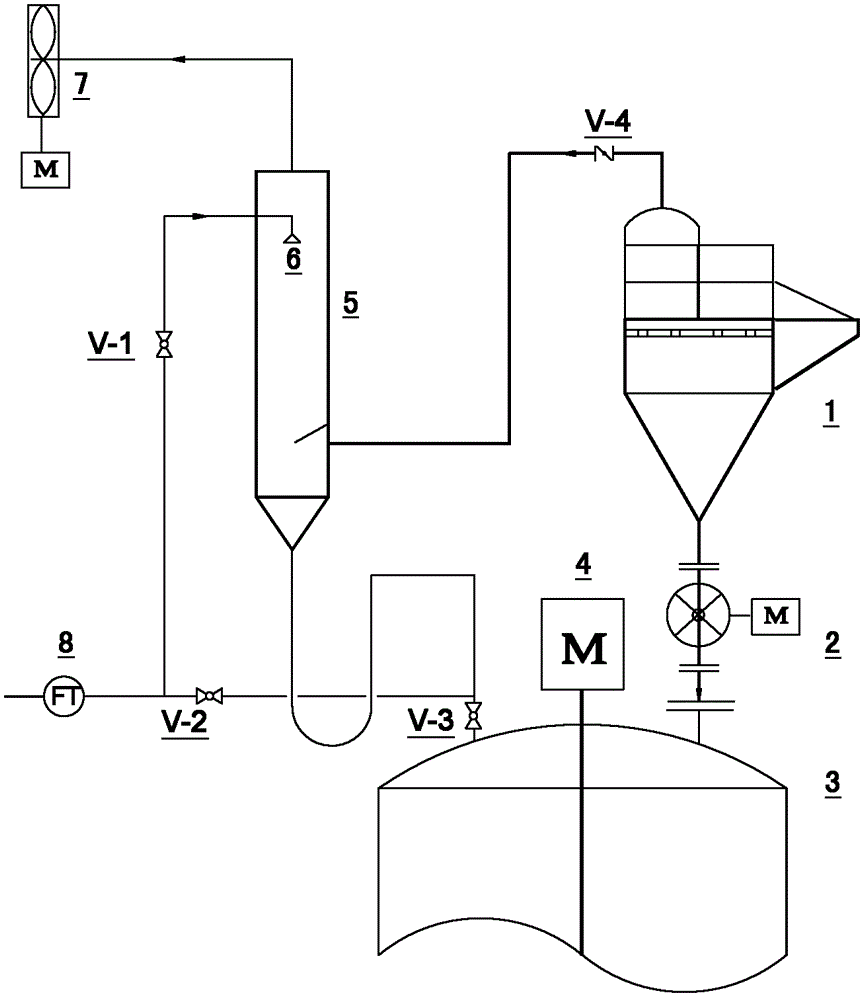

[0021] Such as figure 1 Shown is a fine-grained lightweight powder blending device, including a powder stocker 1, a speed-adjustable feeder 2, a batching tank 3, a liquid supply device, a dust collector 5, and an atomizer The spraying device of the nozzle 6 and the ventilator 7, the upper part of the powder stocker 1 is provided with a powder feeding port and an air discharge port, the middle part is a dust raising area, and the lower part is a feeding cone, and above the feeding cone is provided A grid plate to prevent foreign matter from falling into; the feeder 2 is provided with a feeder inlet and a feeder outlet; the batching tank 3 is provided with a batching tank feed port and a batching tank inlet There is an agitator 4 in it; the dust collector 5 is a cylindrical hollow cavity, the upper end is provided with a vent, and the lower end is provided with a dust c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com