Dry-type paper-making method reengineering tobacco production process

A technology for reconstituted tobacco leaves and production process, which is applied in the field of the production process of reconstituted tobacco leaves by a dry papermaking method, and can solve the problems of insufficient surface roughness, poor air permeability, and difficulty in reaching the coating rate and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, setting the finished product flake quantification as 70g / m 2 , spreading rate ≈78%, filling value ≈7.0cm 3 / g.

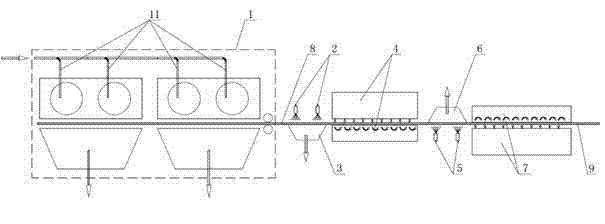

[0023] (1) Metering and crushing: The fluff pulp fiber raw material with a dryness ≥ 80% is transported to the dry air-flow sedimentation molding head 1 through the feeding air duct 11, and the fiber concentration in the feeding air duct is set to 1.5g / m 3 ;

[0024] ⑵Substrate forming: The substrate is made on the air-settling forming head 1 of the dry-laid paper machine, and the basis weight is set to 18g / m 2 , moisture 85%;

[0025] (3) One-time spraying: Spray smoke powder and glue mixture on the front of the substrate 8. When spraying, there is a negative pressure suction box 3 on the back of the substrate 8 for negative pressure vacuum suction, and the absolute dry weight of the spraying is set to 24.0g / m 2 ;

[0026] (4) One-time drying: After the first spraying, the substrate 8 is sent to the No. 1 drying oven 4 for drying until the...

Embodiment 2

[0029] Embodiment two, setting finished product sheet quantification as 110g / m 2 , spreading rate ≈64.8%, filling value ≈6.3cm 3 / g, moisture ≤12%, of which non-tobacco substances ≈32%.

[0030] (1) Metering and crushing: transport the mixture of fluff pulp fiber and tobacco fiber with a dryness ≥ 80% to the dry air-flow sedimentation forming head 1 through the feeding air pipe 11, and set the fiber concentration in the feeding air pipe to 6g / m 3 , set the mixing ratio of tobacco fiber and fluff pulp fiber mixture to 1:4 by mass percentage;

[0031] ⑵Substrate molding: The substrate is made on the air-settling forming head 1 of the dry-laid paper machine, and the basis weight is set to 40g / m 2 , moisture 85%;

[0032](3) One-time spraying: spray smoke powder and rubber mixture on the front of the substrate 8, when spraying, there is a negative pressure suction box 3 negative pressure vacuum suction on the back of the substrate 8, and set the absolute dry weight of spraying ...

Embodiment 3

[0036] Embodiment three, setting finished product sheet quantification as 90g / m 2 , spreading rate ≈51%, filling value ≈6.0cm 3 / g, moisture ≤12%, of which non-tobacco substances ≈3%.

[0037] (1) Metering and crushing: transport the tobacco fiber material with a dryness ≥ 80% to the dry air-flow sedimentation forming head 1 through the feeding air pipe 11, and set the fiber concentration in the feeding air pipe to 3g / m 3 ;

[0038] ⑵Substrate molding: The substrate is made on the air-laid paper machine air-settling forming head 1, and the basis weight is set to 45g / m 2 , moisture 85%;

[0039] (3) One-time spraying: Spray smoke powder and rubber mixture on the front of the substrate 8. When spraying, there is a negative pressure suction box 3 on the back of the substrate 8 for negative pressure vacuum suction, and the absolute dry weight of the spraying is set to 20g / m 2 ;

[0040] (4) One-time drying: After the first spraying, the substrate 8 is sent to the No. 1 drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com