Large current source for running test of direct-current transmission converter valve and compensation method thereof

A technology of operation test and direct current transmission, which is applied in the direction of circuit breaker test, measurement of electricity, measurement of electric variables, etc., can solve problems such as test circuit and test equipment hazards, and achieve the effect of eliminating DC components and avoiding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

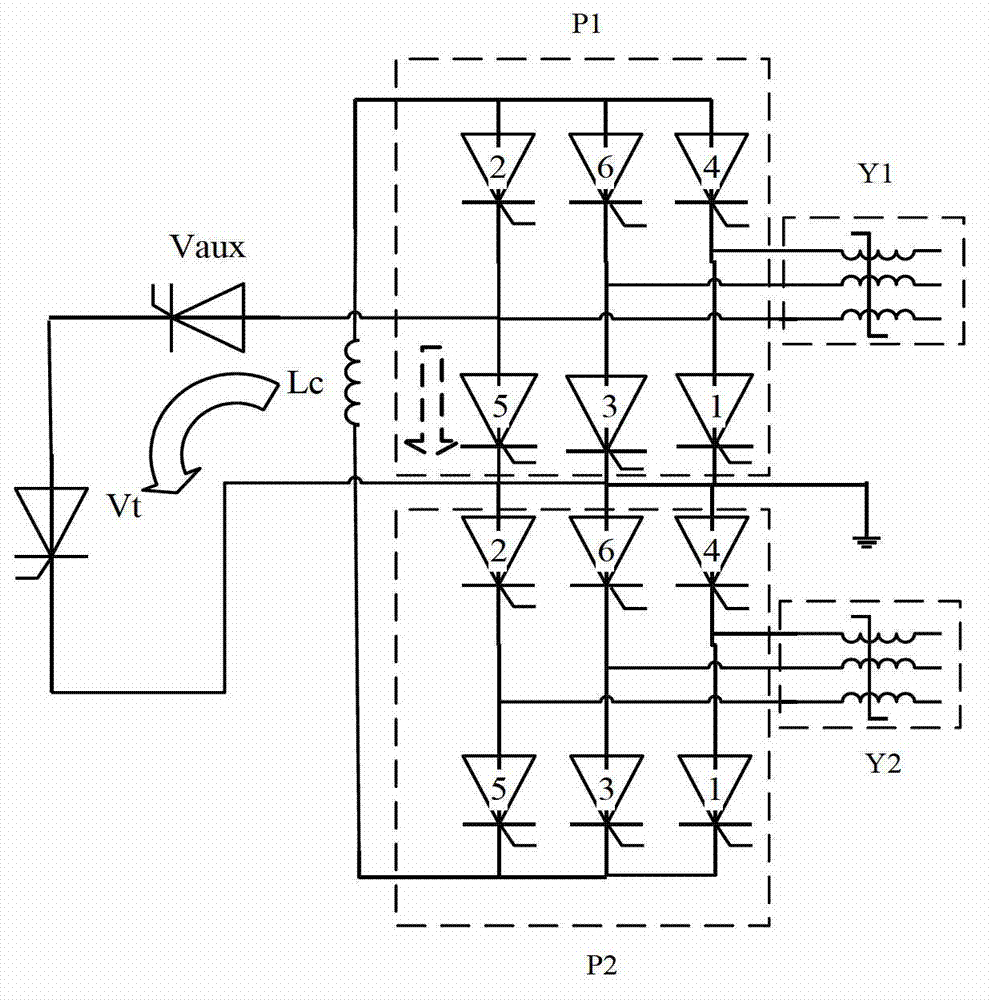

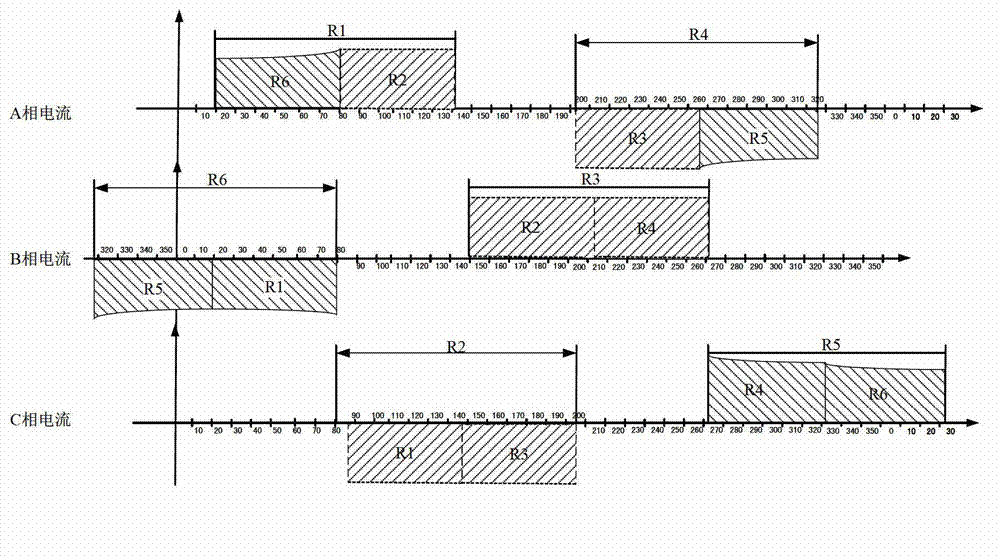

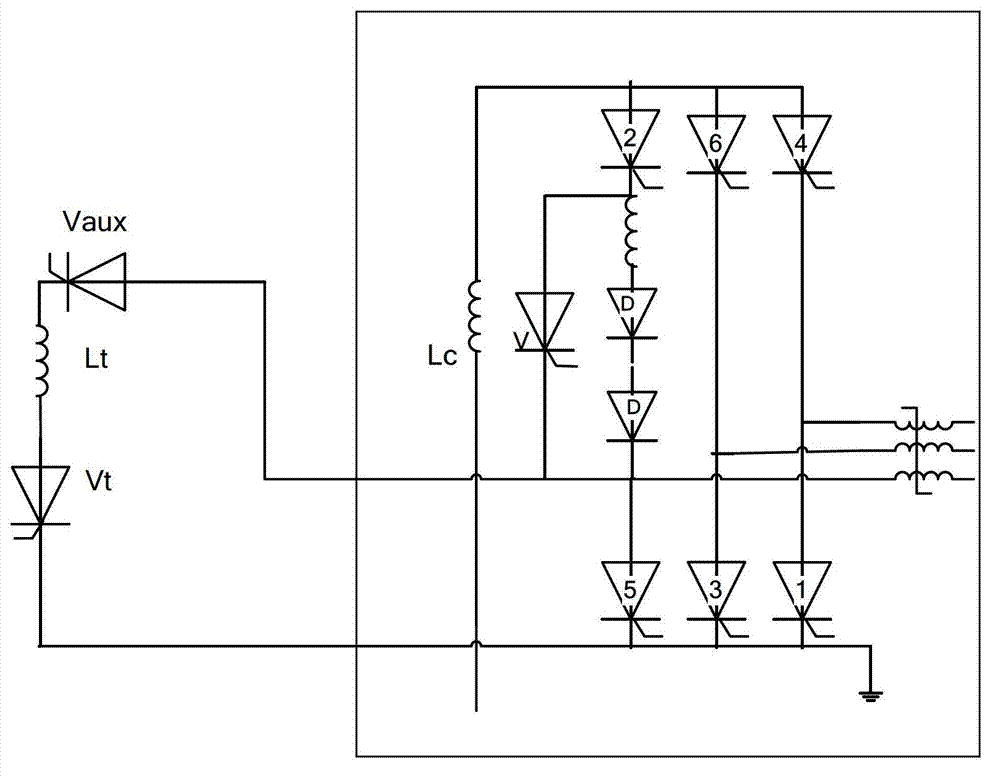

[0013] During the operation test of the high-voltage DC converter valve, the current source converts the energy of the distribution network into a low-voltage and high-current on the valve side through the converter transformer, and outputs a large current through back-to-back double 6 pulses. Since the current source of the test circuit adopts double 6-pulse back-to-back operation mode, the output waveform is close to the actual situation in the project, and the test mode adjustment flexibility is good. Therefore, during normal operation, the energy provided by the converter transformer is only used to supplement the energy lost in the turn-on and turn-off of the thyristor in the test loop and the loop resistance loss, and this part of energy is relatively small. The power requirements for the current source are small, and with appropriate re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com