Flexible sensor capable of detecting ammonia at normal temperature and preparation method thereof

A flexible sensor and normal temperature technology, applied in the field of ammonia sensor, can solve the problems of low selectivity, inflexibility, and insufficient sensitivity coefficient, and achieve the effects of avoiding environmental pollution, good adsorption, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method comprises the following steps:

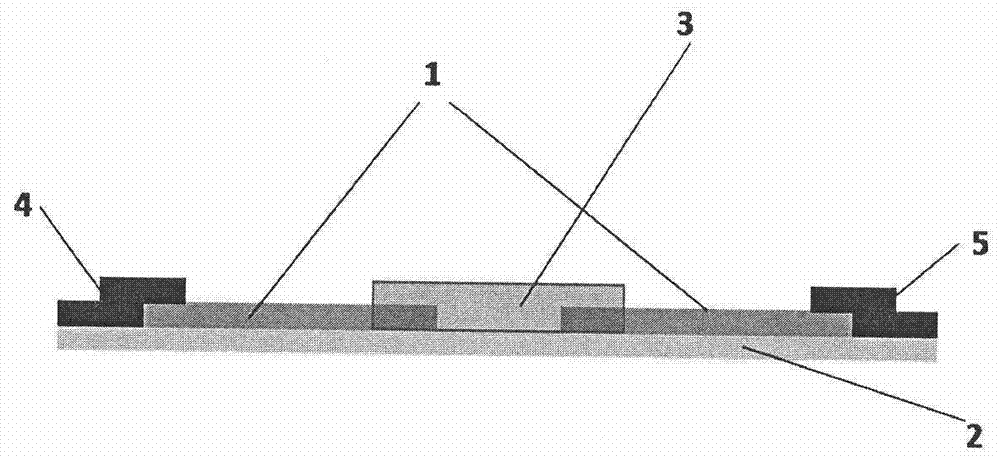

[0026] a Preparation of flexible sensor nano-silver layer two-electrode electrode 1

[0027]Select substrate photo paper 2, and use Dimatix Materials Printer-2800 inkjet printing device to spray-print nano-silver solution with a particle size of 40-82nm and a concentration of 1.10-2.60g / ml on the protective film containing photosensitive emulsion layer of photo paper 2 After several times of spray printing, a symmetrical two-electrode electrode 1 with a nano-silver layer is prepared. Finally, the thickness of the nano-silver layer is 8-30 microns. On the surface of the protective film containing the photosensitive emulsion layer of the photographic paper 2, inkjet prints nano The silver solution is mainly to improve the conductivity of the sensor.

[0028] Wherein, the nano-silver layer two-electrode type electrode 1 is 8-35 mm long and 2-15 mm wide, and the interval between the nano-silver layer two-electrode typ...

Embodiment 1

[0035] a Preparation of flexible sensor nano-silver layer two-electrode electrode

[0036] Select the substrate photo paper, and use the Dimatix Materials Printer-2800 inkjet printing device to print the nano-silver solution with a particle size of about 40nm and a concentration of 1.10g / ml on the surface of the protective film containing the photosensitive emulsion layer of the photo paper, choose 80 Dry at ℃ for 50 minutes to prepare a symmetrical nano-silver layer two-electrode electrode, the thickness of the nano-silver layer is about 8 microns;

[0037] Among them, the nano-silver layer two-electrode electrode is 8mm long and 2mm wide, and the interval between the nano-silver layer two-electrode electrodes is 1.0mm;

[0038] b Preparation of flexible sensor SWNTs-PABS functional layer

[0039] Dissolve the single-walled carbon nanotube particles modified by diethylpropynylamine formate in the deionized water system, and disperse them by high-frequency ultrasound at a fre...

Embodiment 2

[0044] a Preparation of flexible sensor nano-silver layer two-electrode electrode

[0045] Select the substrate photo paper, and use the Dimatix Materials Printer-2800 inkjet printing device to print the nano-silver solution with a particle size of about 60nm and a concentration of 1.50g / ml on the surface of the protective film containing the photosensitive emulsion layer of the photo paper, choose 70 Dry at ℃ for 10 minutes to prepare a symmetrical nano-silver layer two-electrode electrode, the thickness of the nano-silver layer is about 14 microns;

[0046] Among them, the nano-silver layer two-electrode electrode is 10mm long and 3mm wide, and the interval between the nano-silver layer two-electrode electrodes is 2.0mm;

[0047] b Preparation of flexible sensor SWNTs-PABS functional layer

[0048] Dissolve the single-walled carbon nanotube particles modified by diethylpropargylamine formate in the deionized water system, and disperse them by high-frequency ultrasound at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com