Hard alloy bar difficultly loosing weld

A technology of hard alloy and alloy strips, applied in the direction of slender components, building components, etc., can solve the problems of easy desoldering, poor welding performance of hard alloy strips, etc., so as to achieve not easy to fall off, improve welding performance, and improve bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

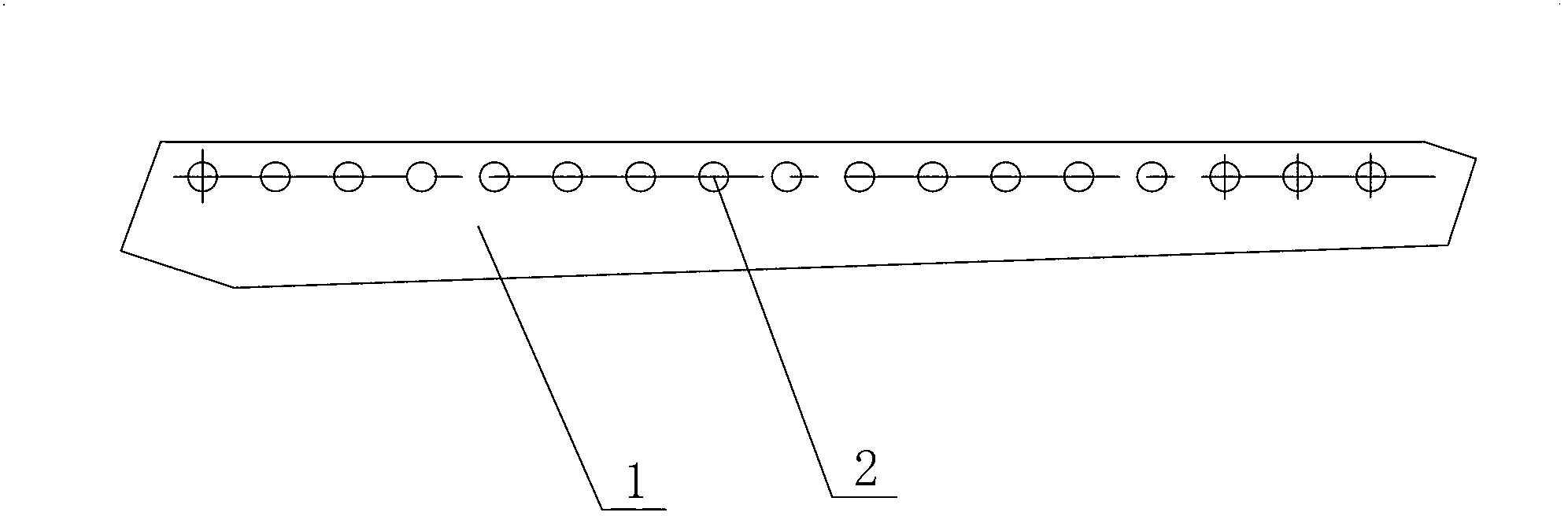

[0011] see figure 1 as shown, figure 1 It is a schematic structural view of the difficult-to-de-solder hard alloy strip provided in Embodiment 1 of the present invention.

[0012] In this embodiment, a cemented carbide strip that is not easy to desoldering includes a long strip-shaped alloy strip body 1, and a plurality of through holes 2 are opened on the alloy strip body 1, and the through holes 2 are evenly distributed in a row. On the alloy bar body 1, the through hole 2 is designed so that when the product is being welded, the welding liquid can effectively fix the alloy bar body 1 and the matrix through the through hole 2, and improve its bonding strength to improve the welding performance of the product. It does not fall off easily.

[0013] The above embodiments have only set forth the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com