Cellulosic fiber fabric reactive dye salt-free deep-color dyeing method

A cellulose fiber and reactive dye technology, applied in dyeing method, fiber treatment, plant fiber and other directions, can solve the problems of low utilization rate of dyes, heavy burden of dyeing wastewater treatment, large amount of salt, etc., achieving obvious effect and affordable cost. Control, easy to operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

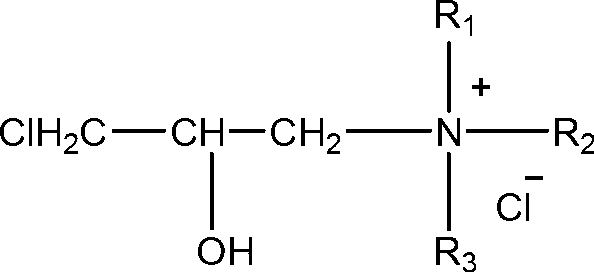

[0055] Prepare modification solution (bath ratio 1:10, cationic modifier 30g / L), heat up to 60°C, add cotton fabric, stir for 5-15min, add alkali agent 15g / L, stir for 15-30min, wash with water, dry .

[0056] Prepare dye solution (bath ratio 1:10, ED-Q black 3.7% owf, Kehuasu 3RS yellow 0.44%owf, Kehuasu 3BSN red 0.19%owf), leveling agent O-250.5g / L, heat up to 60 ℃, add the modified cotton fabric, stir and dye for 20~30min, add 2g / L substitute alkali, stir and keep warm for dyeing for 30~45min, cool down to room temperature at 2~5℃ / min, soap wash (neutral soap flakes 2g / L L, soda ash 2g / L, 95°C, 10min, liquor ratio 1:20), washed with water, dried, and tested for performance (results are shown in Table 1).

[0057] Table 1

[0058]

Embodiment 2

[0060] Prepare modification solution (bath ratio 1:10, cationic modifier 45g / L), heat up to 60°C, add cotton fabric, stir for 5-15min, add alkali agent 15g / L, stir for 15-30min, wash with water, dry .

[0061] Prepare dye solution (bath ratio 1:10, ED-Q black 3.7% owf, Kehuasu 3RS yellow 0.44%owf, Kehuasu 3BSN red 0.19%owf), leveling agent O-250.2g / L, heat up to 60 ℃, add modified cotton fabric, stir and dye for 20~30min, add substitute alkali 2g / L, stir and keep warm for dyeing for 30~45min, cool down to room temperature at 2~5℃ / min, soap wash (neutral soap flakes 2g / L, Soda ash 2g / L, 95°C, 10min, liquor ratio 1:20), washed with water, dried, and tested for performance (results are shown in Table 2).

[0062] Table 2

[0063]

Embodiment 3

[0065] Prepare modification solution (bath ratio 1:10, cationic modifier 15g / L), heat up to 60°C, add modal fiber fabric, stir for 5-15min, add alkali agent 15g / L, stir for 15-30min, wash with water, dry Dry.

[0066] Prepare dye solution (bath ratio 1:10, ED-Q black 3.7% owf, Kehuasu 3RS yellow 0.44%owf, Kehuasu 3BSN red 0.19%owf), leveling agent O-251g / L, heat up to 60°C , adding modified modal fiber fabric, stirring and dyeing for 20~30min, adding 2g / L of substitute alkali, stirring and keeping warm for dyeing for 30~45min, cooling to room temperature at 2~5℃ / min, soaping (neutral soap flakes 2g / L, Soda ash 2g / L, 95°C, 10min, liquor ratio 1:20), washed with water, dried, and tested for performance (results are shown in Table 3).

[0067] table 3

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com