Mixed molten salt as heat transfer and storage medium low in melting point

A technology of mixing molten salt and heat storage medium, which is applied in the field of physical heat transfer and energy storage in high-tech, can solve the problems of inability to provide thermal properties, general thermal stability, and high melting point, so as to simplify the initial operation procedure and increase safety and stability performance, and the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

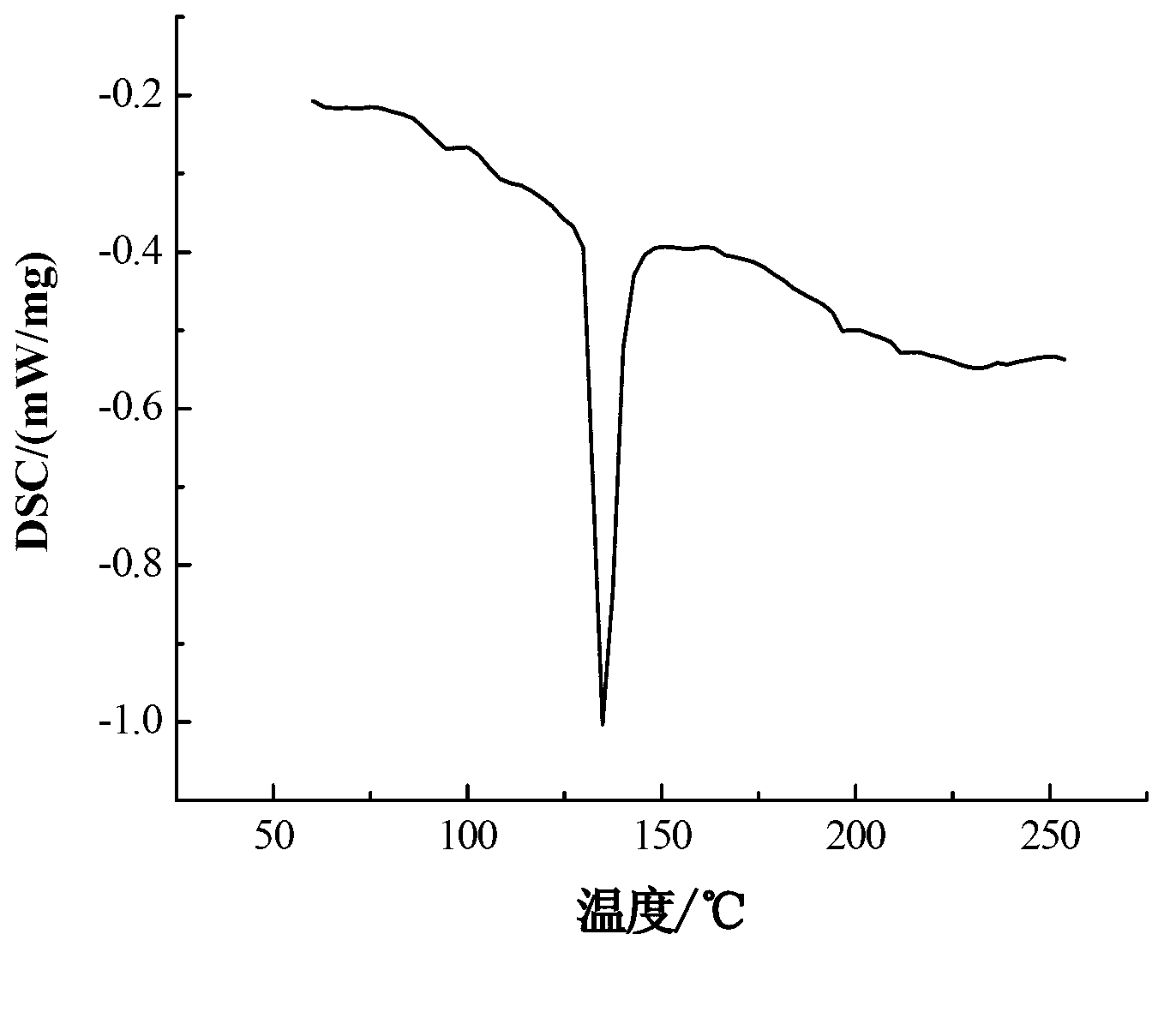

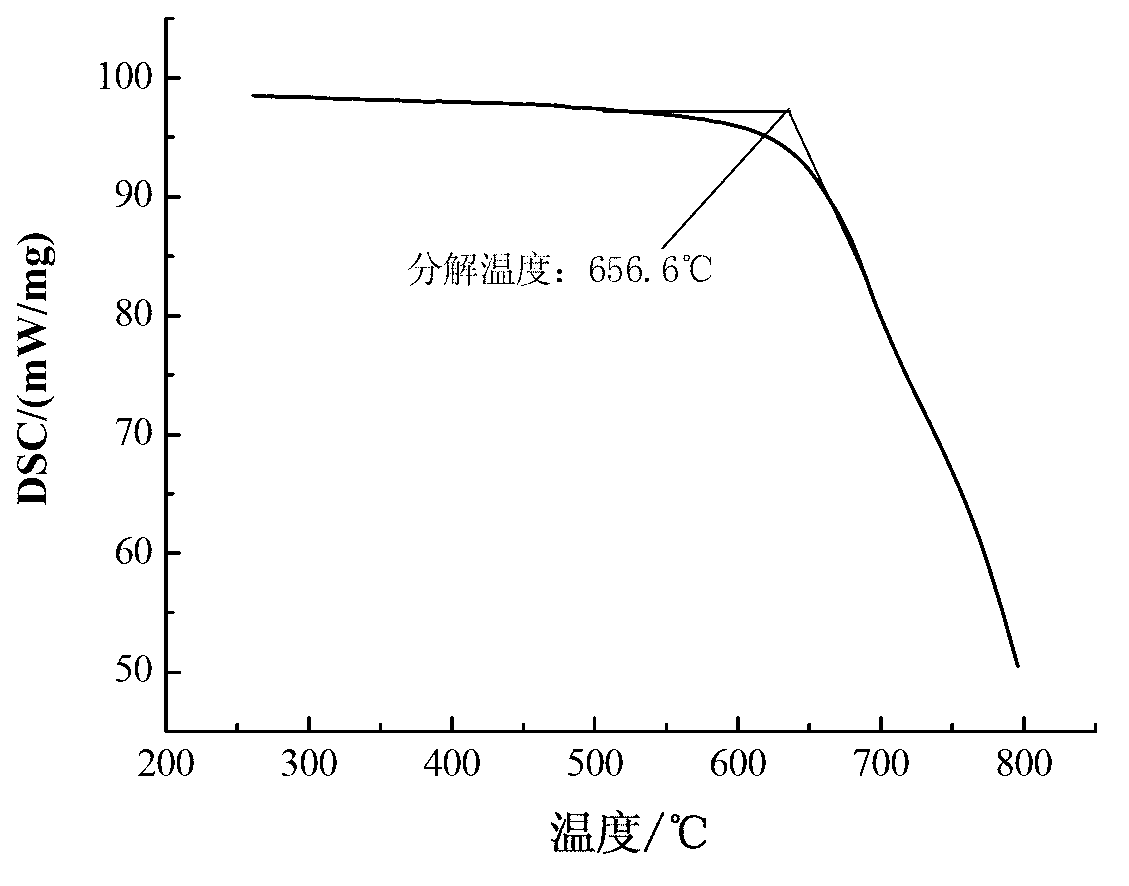

[0036] This mixed molten salt is composed of 10wt% calcium nitrate, 60wt% potassium nitrate, 20wt% sodium nitrate, and 10wt% sodium nitrite. Through DSC (differential scanning calorimetry) analysis, its melting point is 130.2°C, According to TG (thermogravimetric technique) analysis, its decomposition temperature is 656.6°C. likefigure 1 Shown is the DSC curve for this sample. figure 2 Shown is the TG curve for this sample.

[0037] Compared with Solar Salt, the melting point of this formula is lowered by nearly 90°C, and compared with Hitec salt, the melting point of this formula is lowered by nearly 15°C, while the decomposition temperature is as high as above 650°C, which has a wider use temperature range.

Embodiment 2

[0039] This mixed molten salt is composed of 10wt% calcium nitrate, 70wt% potassium nitrate, 10wt% sodium nitrate, and 10wt% sodium nitrite. Through DSC (differential scanning calorimetry) test and analysis, its melting point is 129.0°C, Compared with Solar Salt, the melting point of this formula is lowered by nearly 90°C, and compared with Hitec salt, the melting point of this formula is lowered by nearly 15°C, while the decomposition temperature is as high as above 680°C, which has a wider use temperature range.

[0040] Secondly, in order to further reduce the melting point of the mixed molten salt, the present invention replaces the sodium nitrite component with lithium nitrate to prepare 16 kinds of quaternary mixed nitrates, and the specific operation method is the same as above. After a lot of experimental analysis, two formulations of molten salt were finally selected.

Embodiment 3

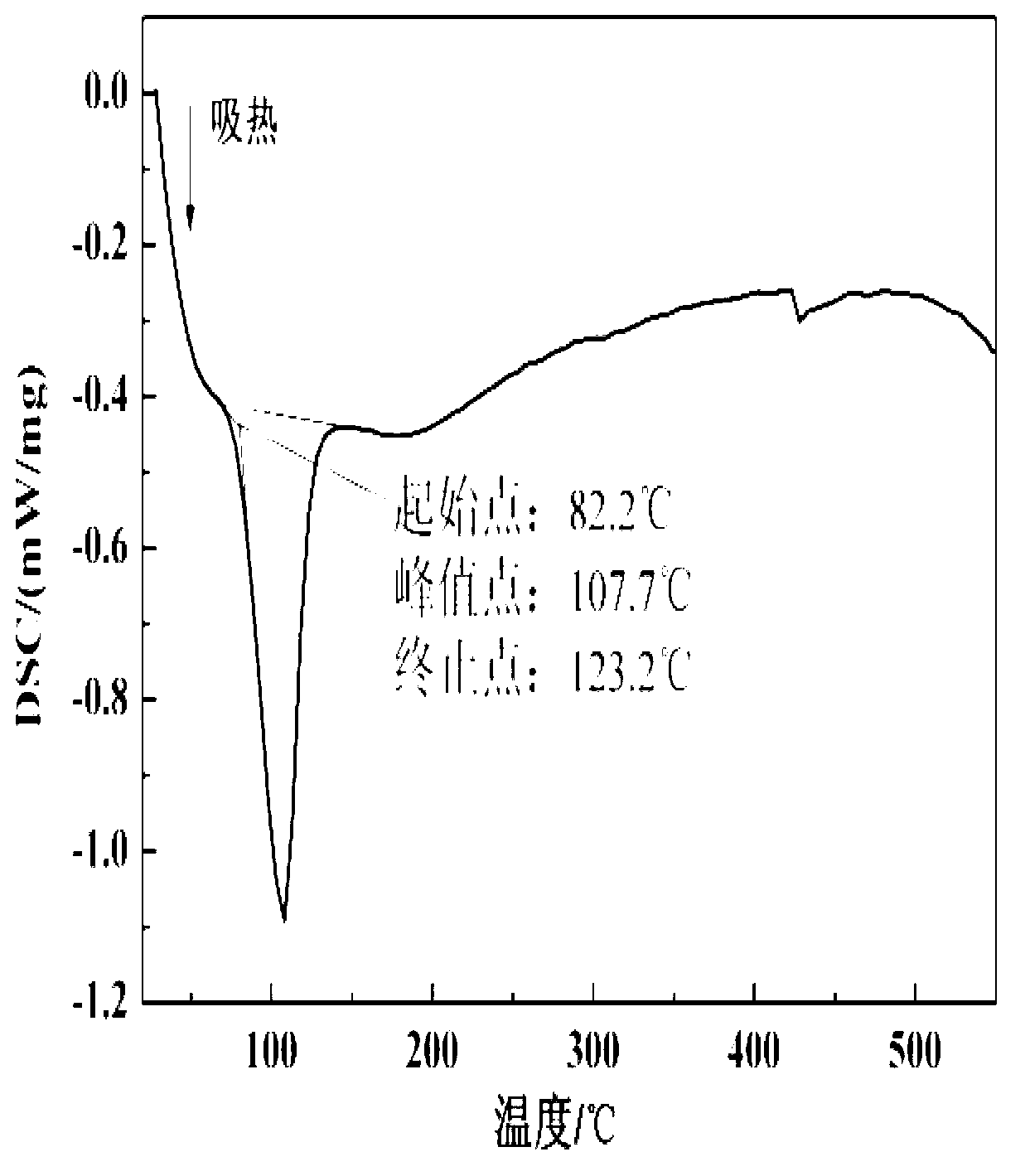

[0042] This mixed molten salt is composed of 20wt% calcium nitrate, 50wt% potassium nitrate, 10wt% sodium nitrate, and 20wt% lithium nitrate. Through DSC (differential scanning calorimetry) test and analysis, its melting point is 82.2 ° C. Heavy technology) analysis, its decomposition temperature is 604.9 ℃. like image 3 Shown is the DSC curve for this sample. Figure 4 Shown is the TG curve for this sample.

[0043] Compared with Solar Salt, the melting point of this formula is lowered by nearly 130°C, and compared with Hitec salt, the melting point of this formula is lowered by nearly 60°C, while the decomposition temperature is as high as above 600°C, which has a wider use temperature range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Density value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com