Method for preparing natural pyrrole derivative from plant brassica rapa L. by extraction, purification and separation

A technology of pyrrole derivatives and turnips, applied in the field of natural product extraction, can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

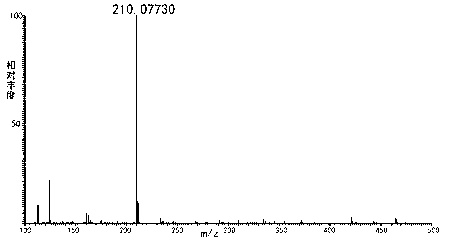

Image

Examples

Embodiment 1

[0024] 2. Add 5000ml of 75% ethanol aqueous solution with glacial acetic acid to adjust the pH value to 3.2, soak for 30 minutes, ultrasonically extract (180w, 25°C, 40kHz) for 30min, filter, add 5000ml of 75% ethanol aqueous solution to the filter residue, and then ultrasonicate (180w , 25°C, 40kHz) ultrasonic extraction for 30min, filter, discard the filter residue, combine the two extraction filtrates, and use a rotary evaporator to concentrate the filtrate to a viscous extract to obtain the extract extract;

[0025] 3. Dissolve the extract in 500ml of distilled water, add an equal volume of ethyl acetate to extract 4 times, combine the ethyl acetate extraction phase, evaporate under reduced pressure to remove the ethyl acetate solvent, and obtain 2.55g of crude product;

[0026] 4. Dissolve 200 mg of the crude product described in step 3 in 5 ml of water, and refine using preparative high performance liquid chromatography;

[0027] Chromatographic column packing: C18 bonde...

Embodiment 2

[0040] 2. Add 15000ml PH=5.0 hydrochloric acid aqueous solution and soak for 7 days, filter, discard the filter residue, and use a rotary evaporator to concentrate the filtrate to a viscous extract to obtain the extract extract;

[0041] 3. Dissolve the extract in 1000ml of distilled water, add an equal volume of ethyl acetate to extract 8 times, combine the ethyl acetate extract phase, evaporate under reduced pressure to remove the ethyl acetate solvent, and obtain 7.1g of crude product;

[0042] 4. Dissolve 300 mg of the crude product described in step 3 in 5 ml of water, and refine using preparative high performance liquid chromatography;

[0043] Chromatographic column packing: C8 bonded silica gel column (250mm*30mm)

[0044] The mobile phase A phase is: 20mmol / L ammonium formate aqueous solution with pH=6.4

[0045] The mobile phase B phase is: acetonitrile

[0046] The gradient program is: 0~5min, A: 2%, B: 98%

[0047] 5~15min, A: 15%, B: 85%

[0048] 15~20min, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com