Electrolyzer for use in electrolytic in-process dressing metallic bond pellet grinding processing

A technology of grinding and electrolysis device, applied in the field of precision grinding and processing, can solve the problems of difficult to meet the processing requirements of high precision and high efficiency, unchecked patents and references, unstable processing accuracy, etc., and achieve the effect of electrolytic sharpening. Sufficient and stable, reducing electrolysis inhomogeneity, improving the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

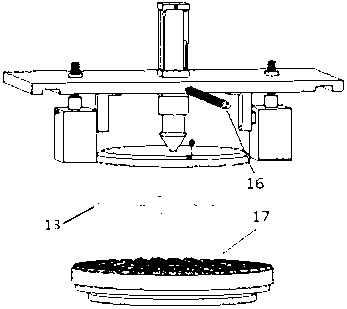

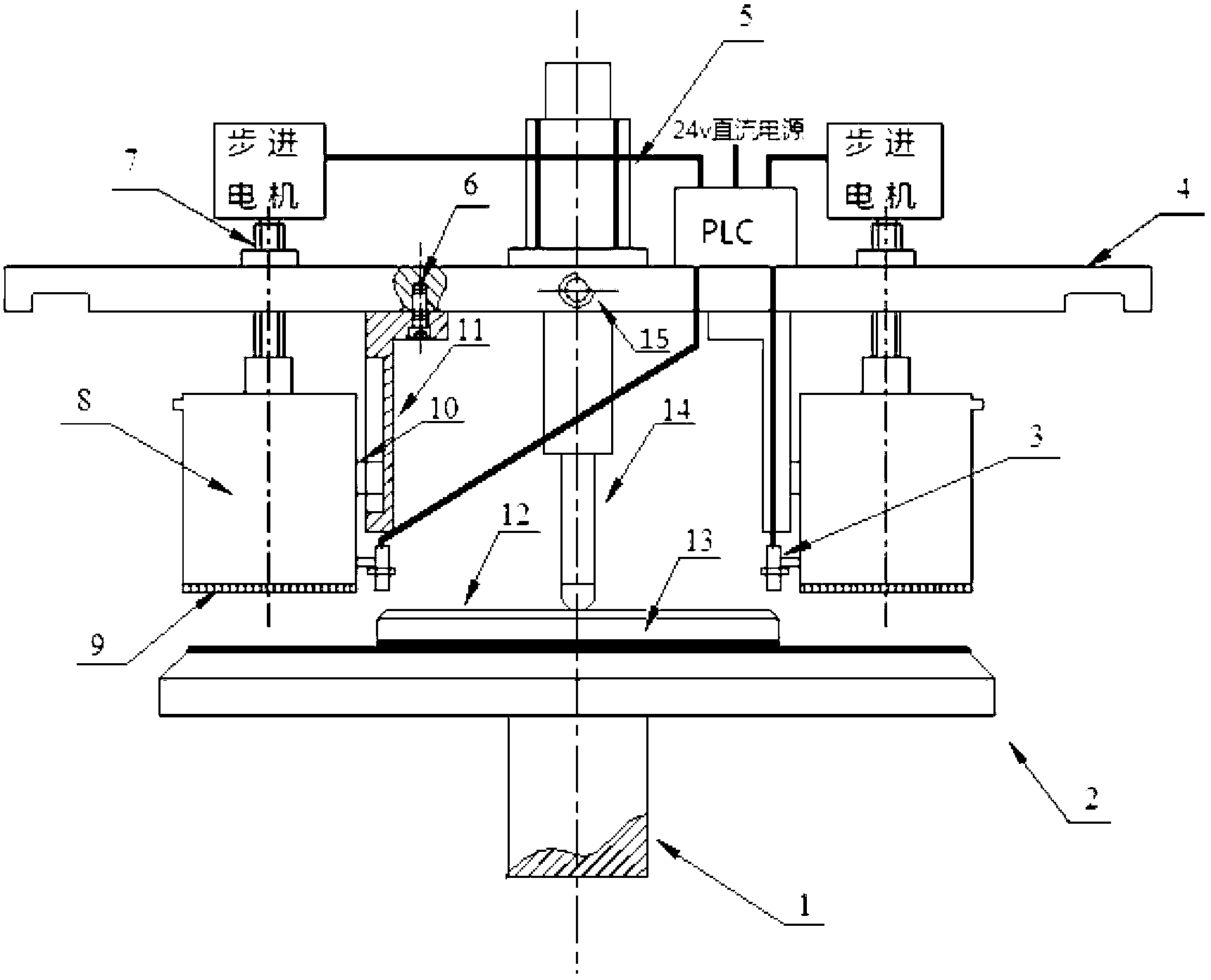

[0015] Such as figure 1 with figure 2 As shown, the device in this embodiment mainly includes a stepper motor, a PLC controller, a sensor 3, a grinding disc 2, a chuck 12, a fan-shaped stainless steel box 8, a flat plate 4, a cylinder 5, a lead screw 7, a guide plate 11, Pressure head 14, leading screw 16, grinding pellet 17. The grinding disc 2 with grinding pellets 17 embedded on the upper surface is installed on the machine tool spindle 1, and is driven to rotate by the machine tool spindle 1; a chuck 12 is arranged above the grinding disc 2, and a coaxial hole is arranged at the lower end of the chuck 12, and the hole The diameter is less than the diameter of the chuck 12, and equal to the diameter of the workpiece disc 13, the height of the hole is less than the height of the chuck 12, and also less than the height of the workpiece; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com