Forming method of TiAl pipe target material in large length-diameter ratio

A large aspect ratio, tube target technology, applied in the field of large aspect ratio TiAl tube target forming, can solve the problems of unable to meet the quality requirements of the target, low material utilization rate, high oxygen content, etc., to achieve overall binding, Realize the effect of densified molding and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

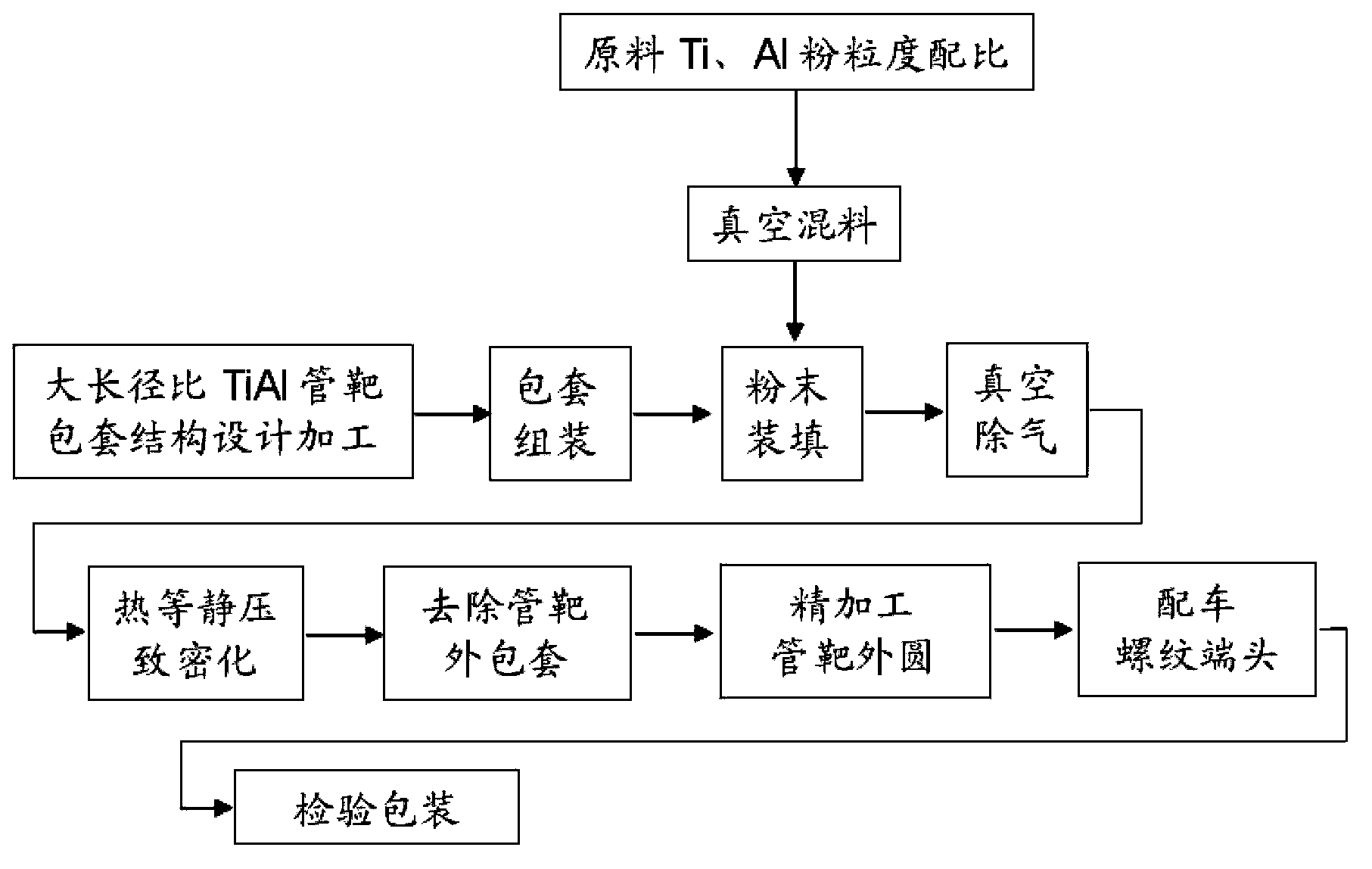

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] to manufacture a size of A tubular TiAl target is taken as an example to illustrate the specific implementation of the method.

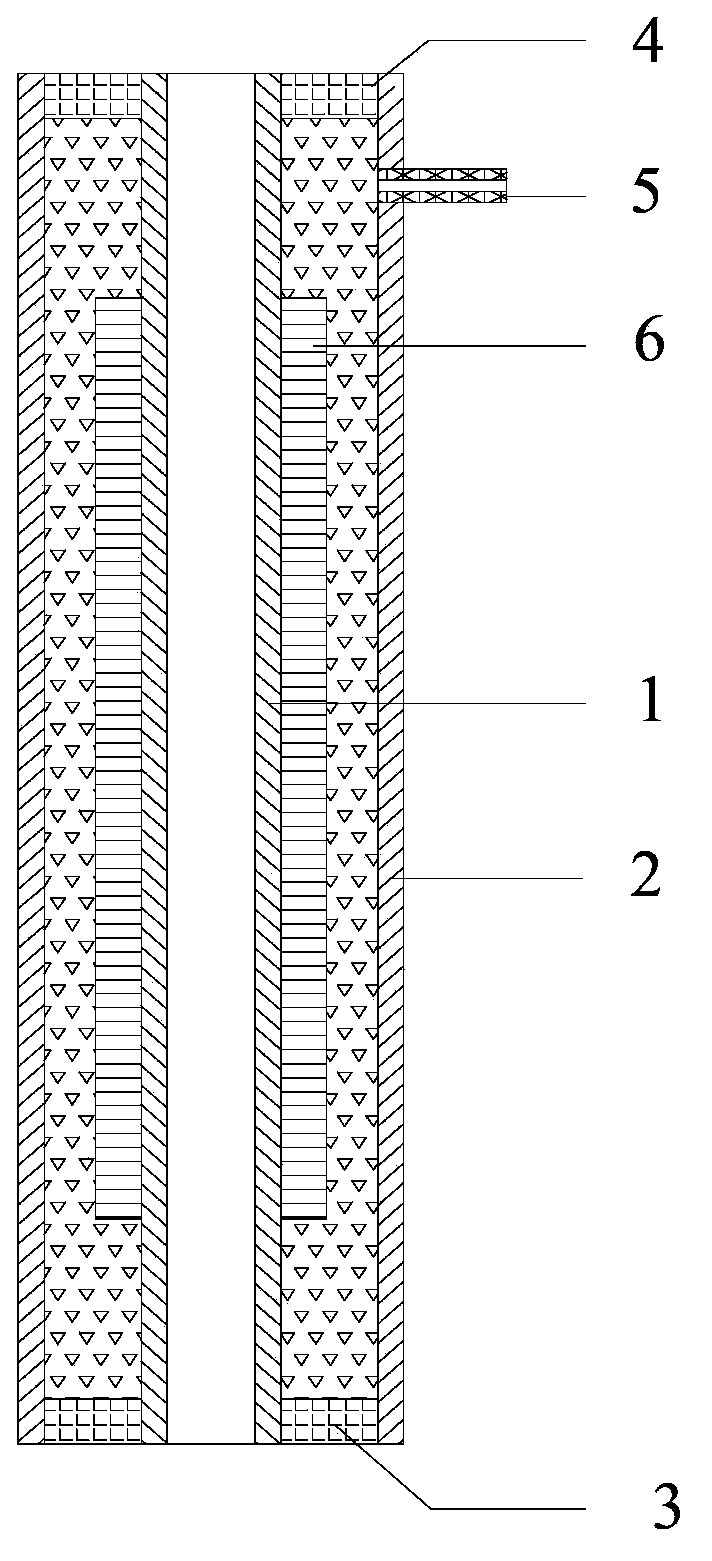

[0034] Step (1), package mold design and processing, assembly

[0035] According to the shape and size of the formed TiAl tube target product, considering the shrinkage of the powder, the overall formation of the target material and the back tube, and the weldability of the sheath, the sheathing mold is designed, and the appropriate sheathing material and structure are selected. The sheath mold of the present invention comprises inner sheath 1, outer sheath 2, sheath bottom cover 3, sheath upper cover 4, air guide tube 5 and back pipe 6, as figure 1 Shown is a schematic diagram of the assembly of the sheath mold in the TiAl tube target forming method of the present invention. First, the cylindrical inner shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com