Four-line segmentation rolling technology of deformed steel bar with diameter of 10mm

A four-wire slit rolling and rebar technology, which is applied in metal rolling, metal rolling, and tool manufacturing, can solve the problems of long distance, large temperature drop at the head of the rolled piece, and easy torsion, etc., to reduce the The effect of production cost, improvement of production efficiency and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

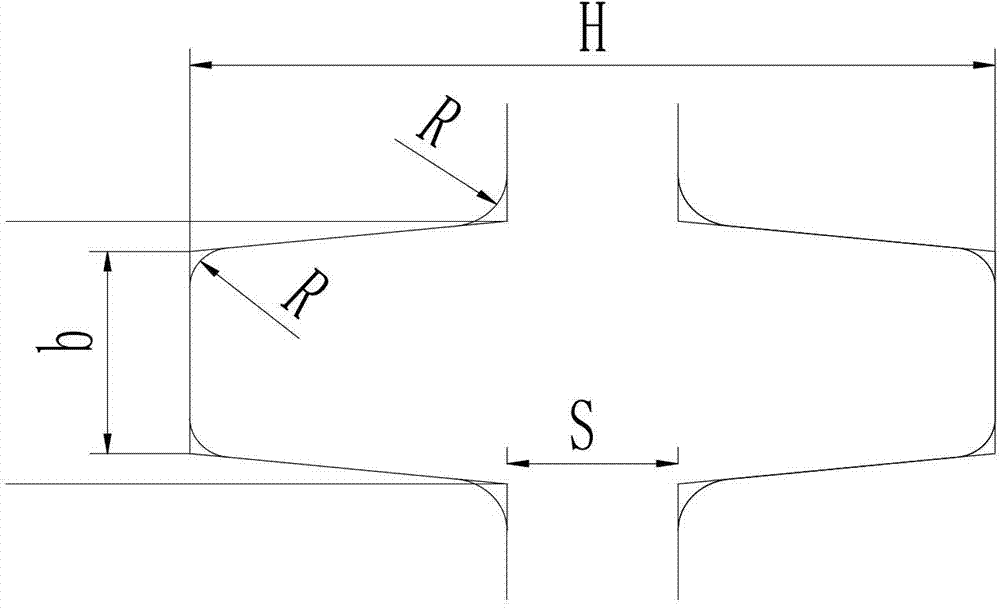

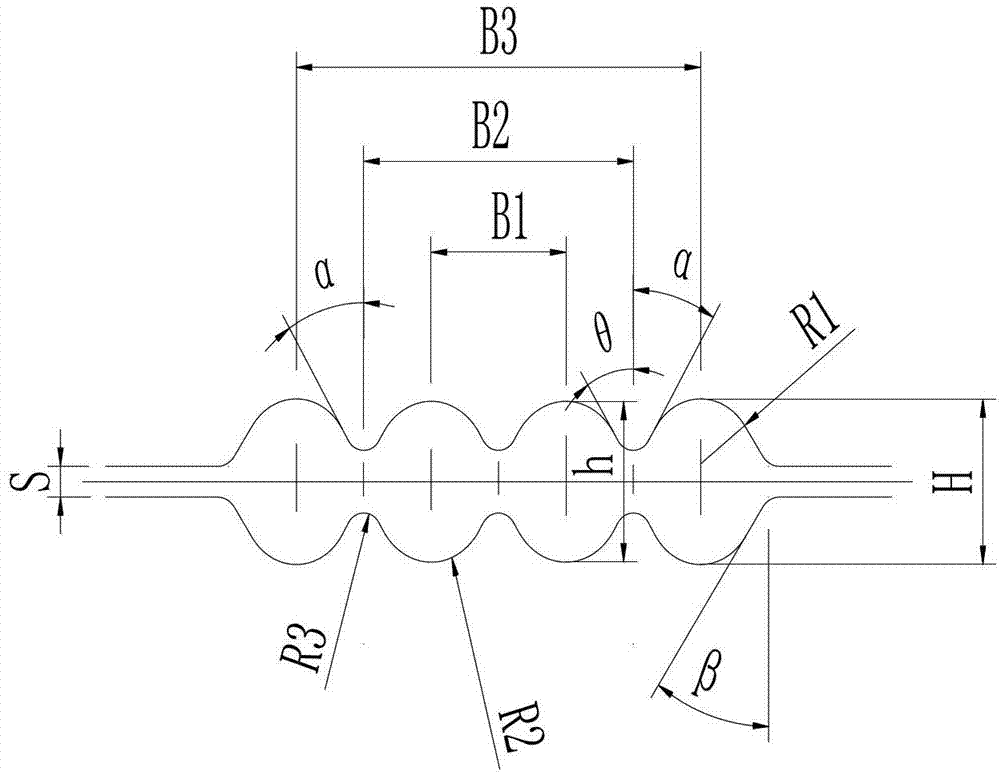

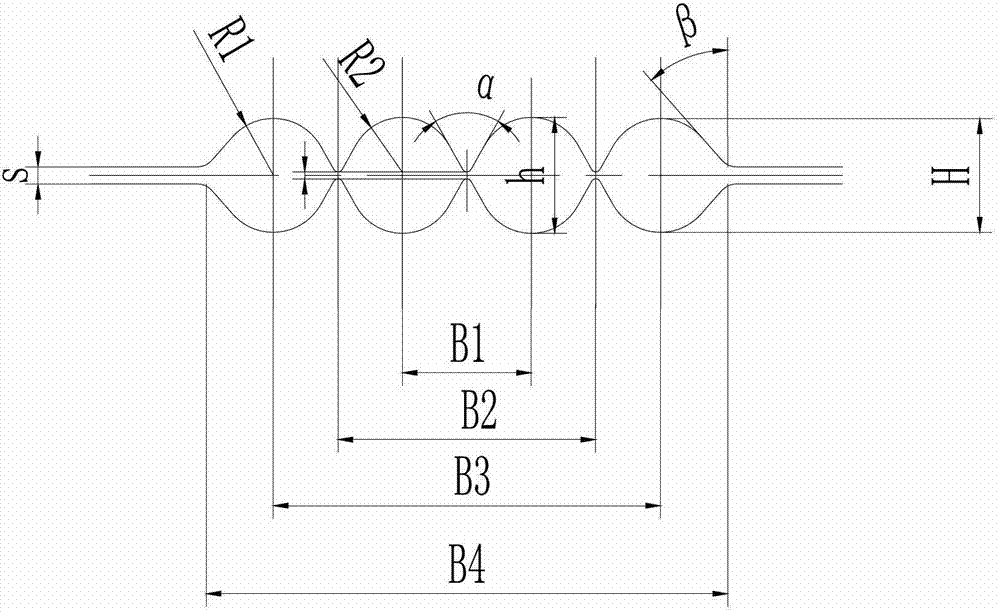

[0027] A bar full continuous rolling production line with 6-8-4 process layout, four-line slit rolling process for ф10mm rebar, using four-slit rolling technology to produce ф10mm rebar, the whole line has a total of 18 rolling mills, arranged alternately horizontally and vertically , all put into use. The 18 rolling mills are divided into three units of rough rolling, intermediate rolling and finishing rolling. Among them, the rough rolling unit has 6 rolling mills, and the rolling mill numbers are 1H, 2V, 3H, 4V, 5H, 6V; the middle rolling unit has 8 rolling mills, numbered 7H, 8V, 9H, 10V, 11H, 12V, 13H, 14V; the finishing rolling mill has 4 rolling mills, and the rolling mill numbers are 15H, 16H / V, 17H, 18H / V; H stands for horizontal sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com