Preparation method of polyether-modified organic silicon defoaming agent

A technology of polyether modification and defoaming agent, which is applied in the direction of foam dispersion/prevention, which can solve the problems of reducing the proportion of silicone and the impact of copolymer performance, and achieves improved safety, good alkali resistance, and good foam suppression performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

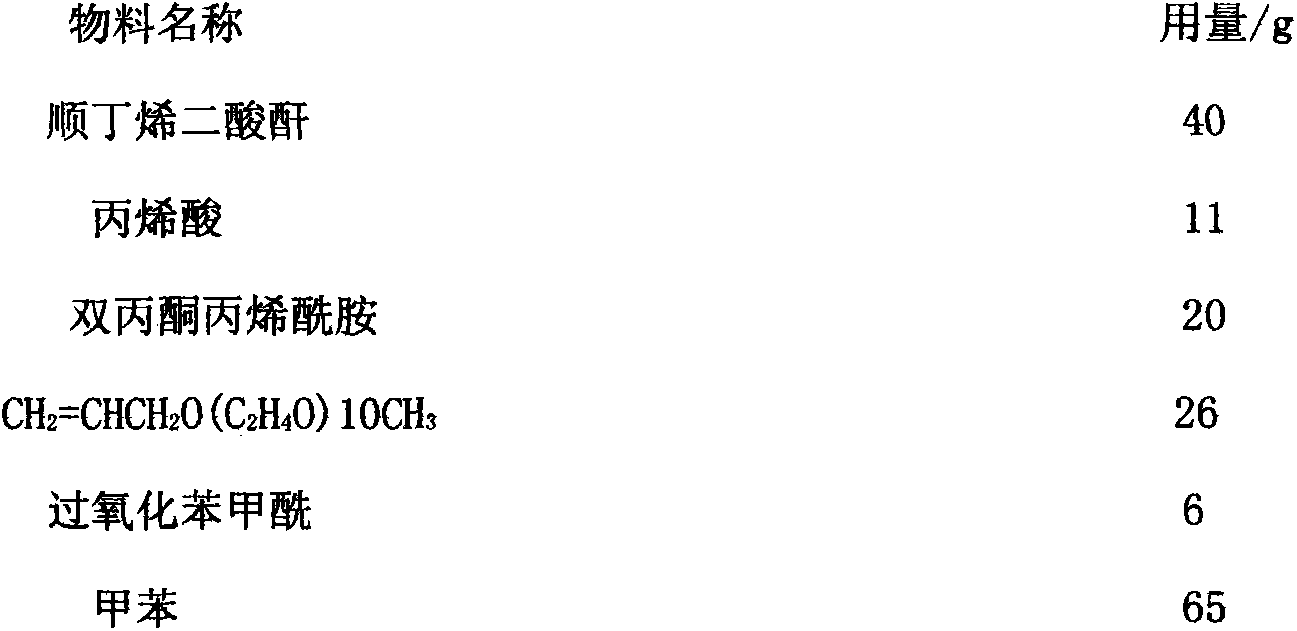

[0024] 1. Polyether polymer preparation examples

[0025]

[0026] The above-mentioned components are loaded into a reactor, which is equipped with a condenser, a nitrogen input pipe, a thermometer and a stirrer. Then, the temperature is increased to 90-100°C under nitrogen atmosphere, and the copolymerization reaction is carried out continuously for 2-4 hours under the protection of nitrogen.

[0027] After the reaction, the toluene was distilled out under reduced pressure at 100°C to obtain a light yellow viscous liquid copolymer.

[0028] The obtained copolymer is hydrolyzed in a 5% NaOH aqueous solution at a temperature of 70° C. for 1-1.5 h to obtain a defoamer hydrolyzate.

[0029] 2. Preparation example of polyether modified organosiloxane defoaming agent

[0030] In a four-necked flask, put the hydrogen-containing silicone oil and the polyether polymer obtained in Example 1 in a ratio of 1:1.5, vacuum dehydration to a water content ≤0.1%, and add 25% of the total mass of the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com