New tobacco pulp treatment method

A treatment method and technology of tobacco pulp, applied in the fields of tobacco, tobacco preparation, application, etc., to achieve the effects of improving extraction rate, low power consumption, and increasing product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

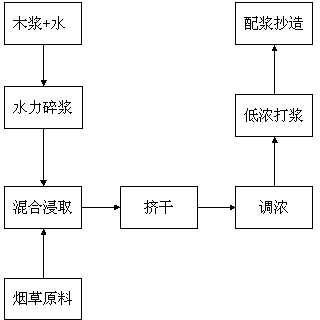

[0021] Such as figure 1 As shown, a new tobacco pulp processing method includes the following steps:

[0022] 1) After mixing wood pulp with water, hydraulic pulping machine is used for 20 minutes at 60℃ to obtain wood pulp slurry, and the mass concentration of wood pulp in the wood pulp slurry is 4%;

[0023] 2) The wood pulp slurry is mixed with the tobacco raw materials and placed in an extraction tank at 55°C for 20 minutes; the addition amount of the wood pulp slurry is 15% of the weight of the tobacco raw materials;

[0024] 3) Squeeze the mixed slurry obtained after leaching to a dryness of 30% (weight percent), then add water to thicken the slurry to a slurry concentration of 4% (weight percent). After the thickening, the slurry enters 5 sets in series The low-consistency refiner performs beating treatment, and the slurry after beating treatment is sent to the paper machine for papermaking.

Embodiment 2

[0026] Such as figure 1 As shown, a new tobacco pulp processing method includes the following steps:

[0027] 1) After mixing wood pulp with water, hydraulic pulping machine is used for 30 minutes at 45℃ to obtain wood pulp slurry. The mass concentration of wood pulp in the wood pulp slurry is 4%;

[0028] 2) After mixing the wood pulp slurry with the tobacco raw materials, place them in an extraction tank at 65°C for 15 minutes; the addition amount of the wood pulp slurry is 25% of the weight of the tobacco raw materials;

[0029] 3) Squeeze the mixed slurry obtained after leaching to a dryness of 30% (weight percentage), and then add water to thicken the slurry to a slurry concentration of 4% (weight percentage). After the thickening, the slurry enters 6 sets in series The low-consistency refiner performs beating treatment, and the slurry after beating treatment is sent to the paper machine for papermaking.

[0030] The comparison between the traditional method and the tobacco pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com