A food product comprising a low temperature rice protein concentrate

A rice protein and concentrate technology, applied in protein food ingredients, protein food processing, food preparation, etc., can solve the problems of fragility, shortened shelf life, setbacks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] The LT process rice protein concentrate was produced using the method described in WO 2005 / 082155 A2. In this example, 10 kg of whole rice was soaked in 40 kg of water overnight while slightly agitated, and then pulverized (more than 95% passed through a 30-mesh sieve) to produce a slurry. The pH of the slurry was adjusted to pH 5.5. Two GSHEs are used to catalyze the hydrolysis of starch: α-amylase G from Genencor-Danisco G997 (2AAU / g starch dry solids) and a granular starch hydrolyzing glucoamylase from Humicola (1.0 GAU / g starch dry solids) (see US Patent No. 7,303,899, incorporated herein by reference). The slurry was incubated at 60°C for 24 hours. A filter press was used to separate the solubilized starch fraction and the residue fraction containing insoluble rice protein to obtain insoluble rice protein in the form of a filter cake. Suspend the filter cake in water, stir well to mix well, and then pass through the filter press again. The rice protein cake from...

Embodiment 2

[0162] The rice protein concentrate was also prepared by the conventional HT process. In a typical experiment, 10 kg of whole rice was soaked in 40 kg of water overnight while slightly agitated, and then crushed (more than 95% passed through a 30-mesh sieve) to produce a slurry. The pH of the slurry was adjusted to pH 5.5. Join G G997 (2AAU / g starch dry solids) and granular starch hydrolyzing glucoamylase from Humicola (1.0 GAU / g starch dry solids), the slurry was incubated at 60°C for 24 hours. Then use a filter press to separate the soluble solids, suspend the insoluble rice protein filter cake in water, stir thoroughly to mix uniformly, and then pass through the filter press again. The rice protein cake from the second filter press was dried in a vacuum oven dryer at 60°C. The composition of the rice protein is shown in Table 2.

[0163] Table 2

[0164] Carbohydrates

Embodiment 3

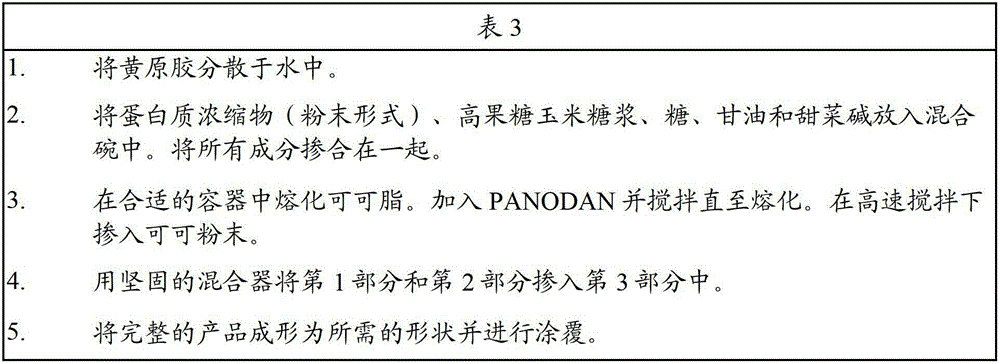

[0166] The rice protein concentrate produced by the LT process was compared with soy protein isolate (Soy Protein Supro516, Solae Company, St. Louis, Missouri, USA) in a chocolate nougat-type core. This type of chocolate core can be used as a component of nutrition bars or candy bars. The rice protein concentrate can also be layered with other bar ingredients. Prepare food products containing protein isolate according to the scheme shown in Table 3:

[0167]

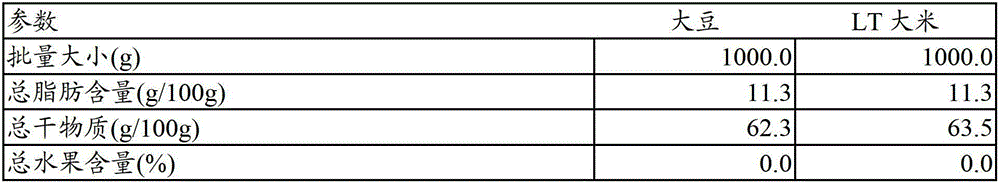

[0168] The composition of the final food product is shown in Table 4. "LT rice" food products contain rice protein concentrate produced by the LT process, and "soy" food products contain soy protein isolate:

[0169] Table 4

[0170]

[0171]

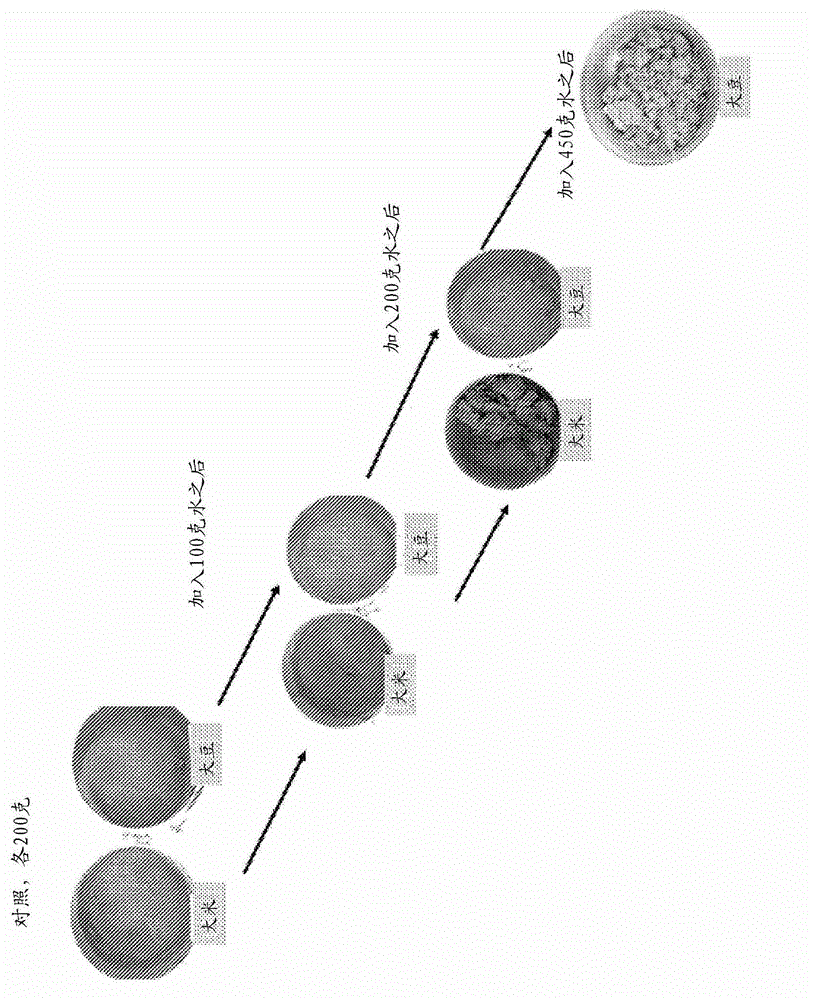

[0172] The water required to prepare the wet dough from the rice protein concentrate is 7% w / w of the final formula. In contrast, the water required to prepare wet dough with soy protein concentrate is 12% w / w of the final formula. Without wanting to be bound by theory, it is belie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com