All-digital electro-magnetic induction heater

A technology of electromagnetic induction and induction heating coils, applied in the direction of induction heating, induction heating control, etc., can solve the problems of slow heating of electric heating tubes, large footprint, and long heating equipment, and achieve high dynamic response, high precision, and low power consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

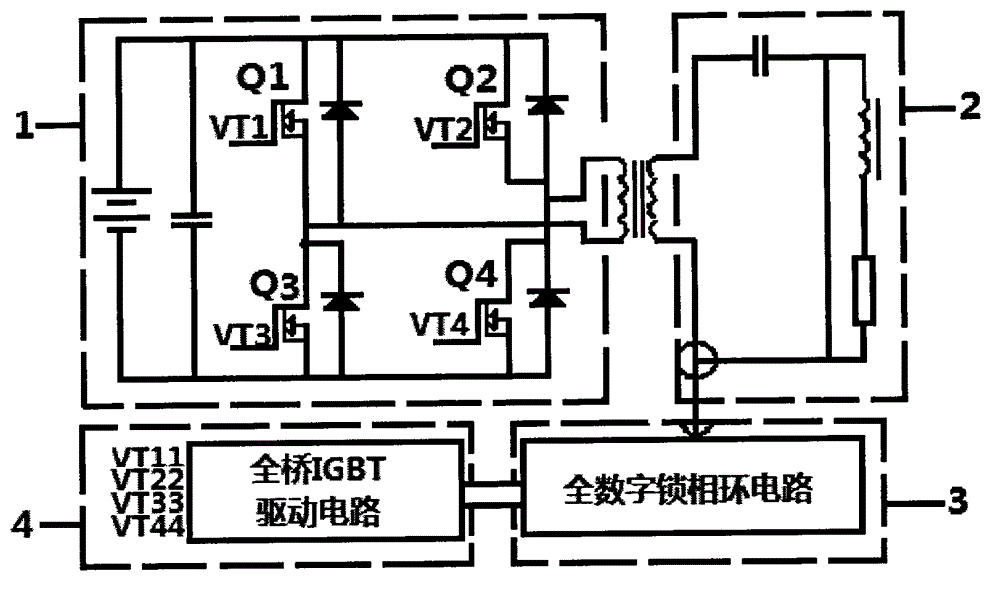

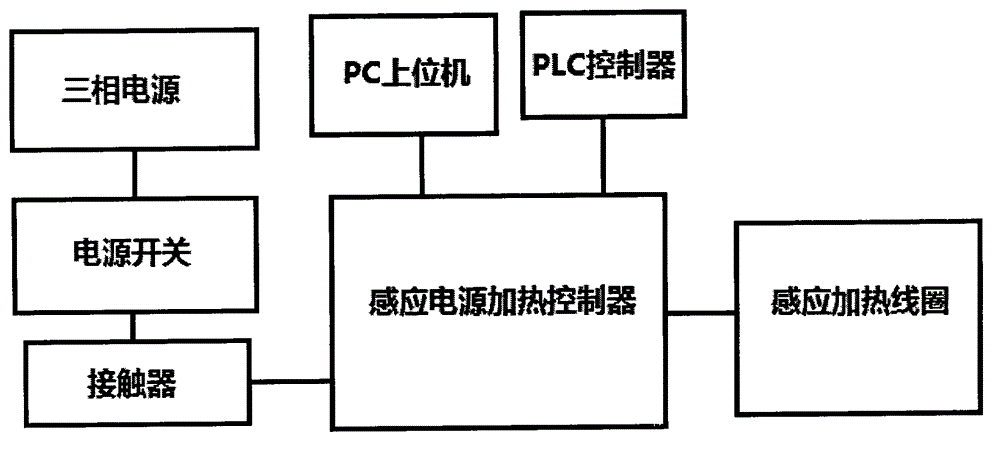

[0022] Such as figure 1 , figure 2 As shown, a full-digital electromagnetic induction heater includes a three-phase power supply, a power switch, and a contactor that are electrically connected in sequence, and also includes an induction power heating controller, and the input end of the induction power heating controller is connected to the contactor. The output end of the induction power heating controller is connected with the PC host computer and the PLC controller respectively, and the output end of the induction power heating controller is connected with an induction heating coil.

[0023] The induction power heating controller includes a full-bridge inverter circuit 1 connected in sequence to make the inverter output an alternating drive waveform, a series resonant circuit 2 consisting of an equivalent circuit formed by the induction heating coil and a heating material, and a An all-digital phase-locked loop circuit 3 for tracking the resonant frequency of the series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com