Laser device wide-temperature circuit

A laser and circuit technology, applied in the field of laser applications, can solve the problems of damaged laser performance, large circuit parameter drift, large volume, etc., and achieve the effects of easy processing and assembly, strong portability, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

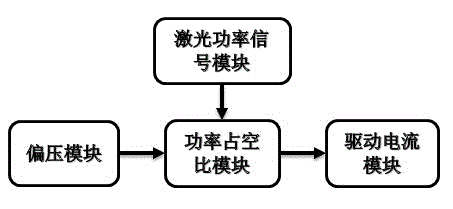

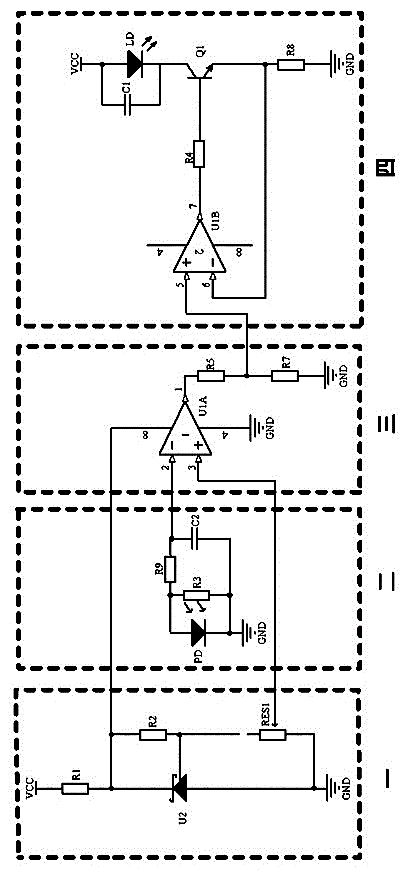

[0021] One: Bias module.

[0022] Two: laser power signal module.

[0023] Three: power duty cycle module.

[0024] Four: drive current module.

[0025] The laser wide temperature circuit of the present invention includes a bias voltage module, a laser power signal module, a power duty ratio control module, and a driving current module, wherein the bias voltage module and the laser power signal module are all connected to the power duty ratio module, and the power duty ratio The module and the drive circuit module are connected. The bias voltage module includes a reference voltage regulator chip and a potentiometer. The reference voltage regulator chip outputs a reference voltage, and then uses the potentiometer to divide the voltage to output a suitable voltage range. The voltage of the middle tap of the potentiometer is used as the setting of the power duty cycle module. value, the power is continuously adjustable within the set range. The laser power signal module inclu...

Embodiment 2

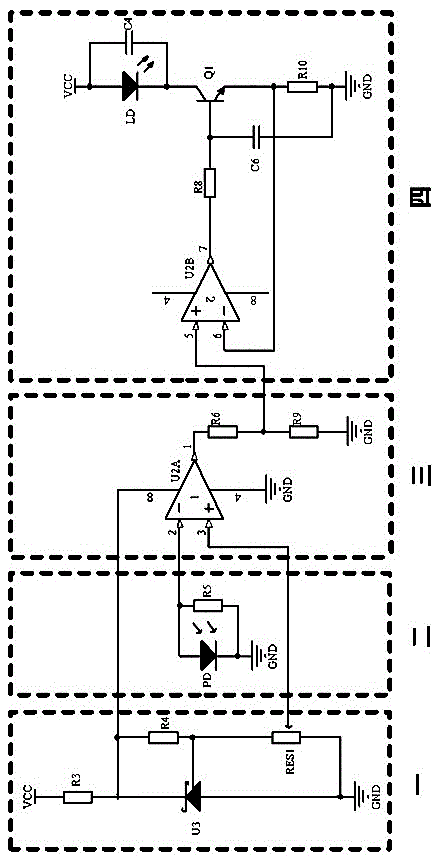

[0036] One: Bias module.

[0037] Two: laser power signal module.

[0038] Three: power duty cycle module.

[0039] Four: drive current module.

[0040] The difference between this embodiment and Embodiment 1 is that the laser power signal module of this embodiment omits the low-pass filter circuit, and also realizes the high-speed import of the power signal to the power duty cycle module for comparison, and quickly adjusts the optical power.

[0041]The laser power signal module of this embodiment: According to the characteristic that the photodiode (PD) generates a corresponding amount of optical feedback current for different power laser light intensity signals, we add an optical feedback component containing a photodiode (PD) to the light output optical path of the laser (APD). The current-voltage conversion is performed on the feedback current, and the laser power signal is imported to the power duty cycle module at high speed, providing an instant power signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com