A convective catalytic combustion method, burner and application thereof

A catalytic burner and catalytic combustion technology, applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of high energy consumption, low purification rate, and low efficiency of catalytic combustion, and achieve pollution reduction, energy conservation, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention provides a convective catalytic combustion method, a burner and its application. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

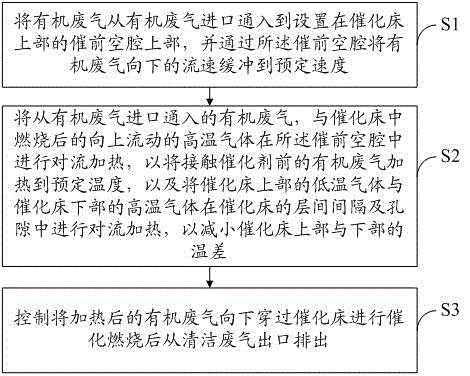

[0038] As a preferred embodiment of the convection catalytic combustion method of the present invention, as figure 1 As shown, it includes the steps:

[0039] S1. Pass the organic waste gas from the organic waste gas inlet to the upper part of the pre-catalyst cavity arranged on the upper part of the catalytic bed, and buffer the downward flow velocity of the organic waste gas to a predetermined speed through the pre-catalyst cavity;

[0040] In the method of the embodiment of this step, before the organic waste gas enters the catalytic bed for cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com