Enclosed grease damping vibration attenuation clutch

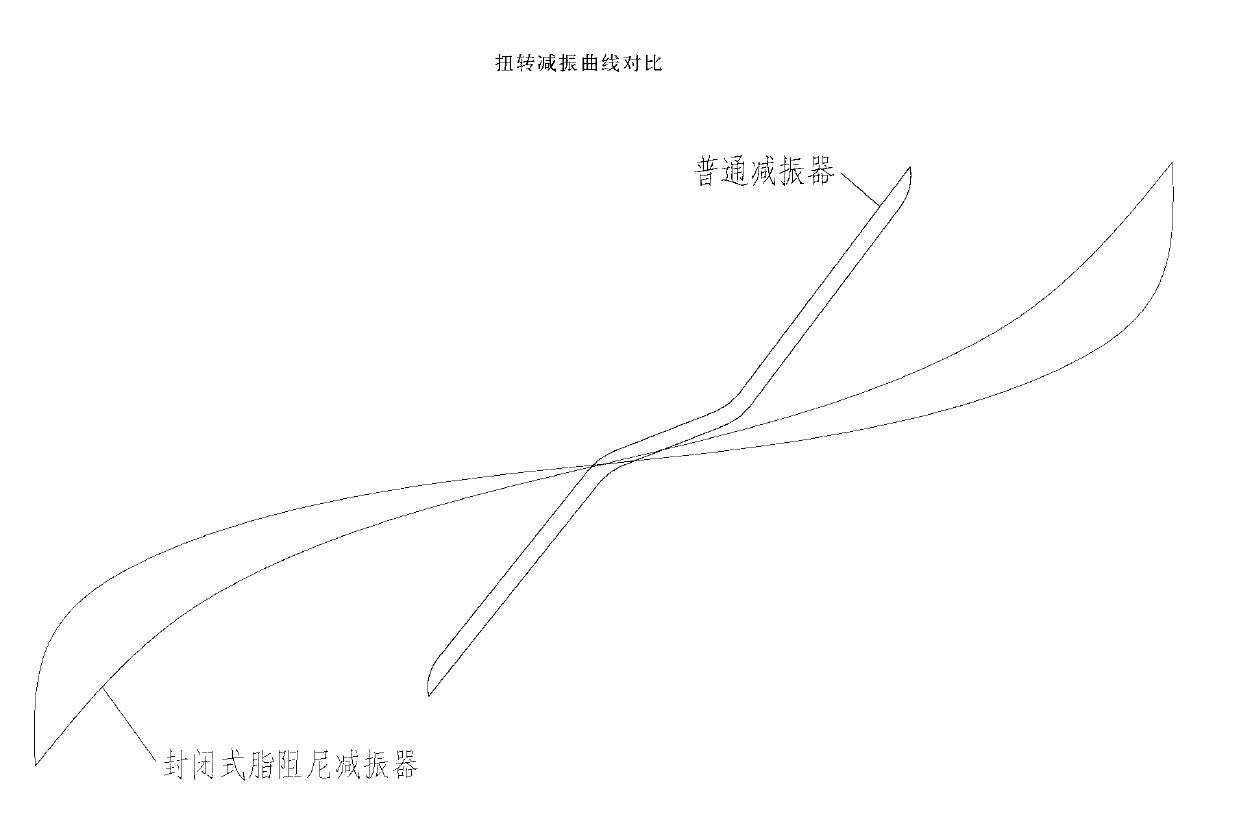

A damping clutch, closed technology, applied in the direction of clutches, friction clutches, solid shock absorbers, etc., can solve the problems of high cost and inability to use large and medium-sized vehicles, and achieve super durability, excellent vibration reduction, and easy adjustment and the effect of controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

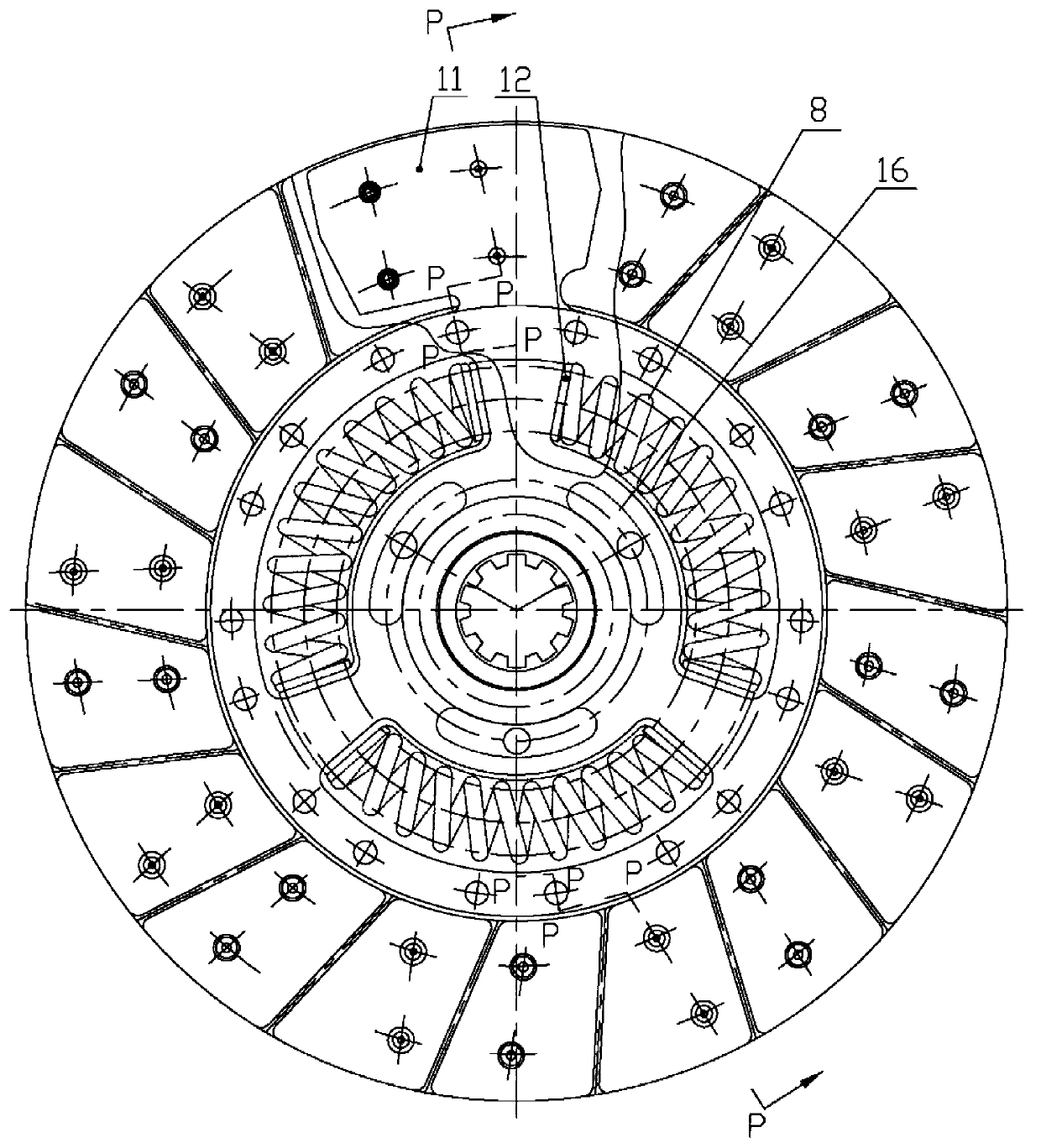

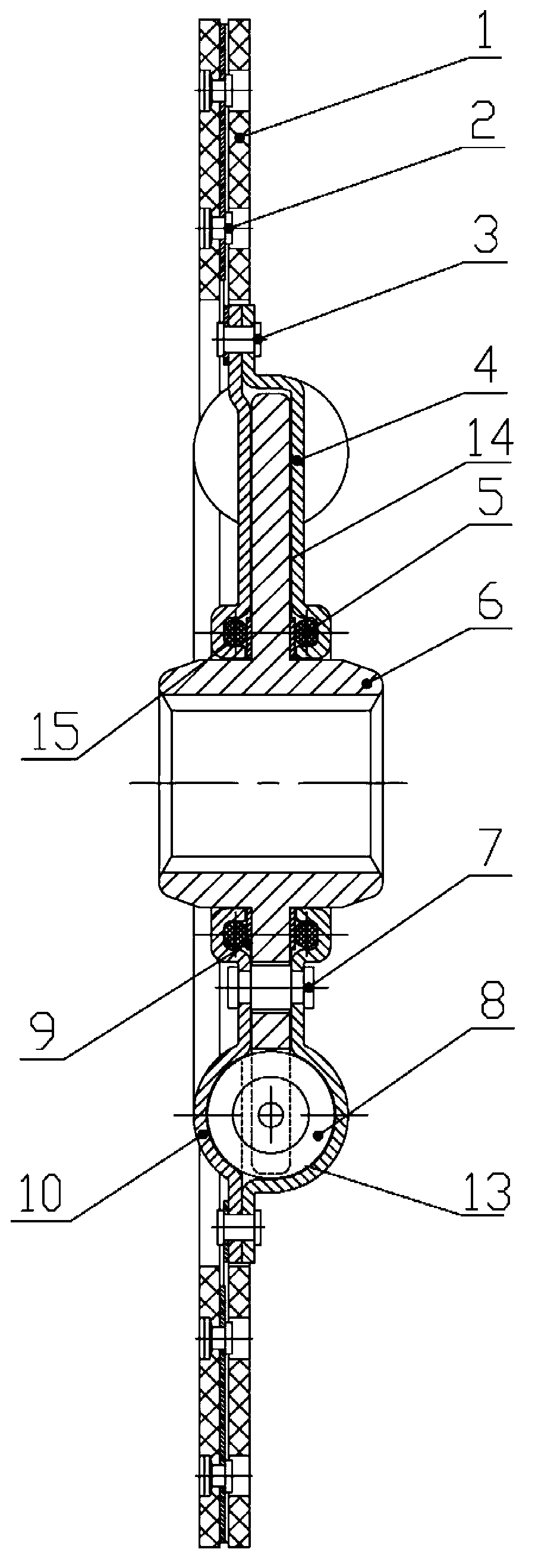

[0021] Example: such as figure 1 , 2 , this kind of closed fat damping vibration damping clutch includes a friction plate 1, a spring plate 11, a damping plate 4, a driven plate 10 and a figure plate hub 6, wherein the friction plate 1 and the spring plate 11 are connected by a friction plate rivet 2, The driven disc 10 and the damping disc 4 form an outer closed annular cavity 13 after being riveted with spring leaf rivets 3. Apply a proper amount of sealant to the contact surface of the vibrating plate 4.

[0022] There are three sections of flat cavities 14 symmetrically distributed in the center of the annular cavity 13, and the annular cavity 13 is divided into three sections. A spring seat 12 is respectively provided at both ends of each section, and a spring seat 12 is provided between the spring seats 12. The spring 8 and the outer circle of the spring seat 12 are consistent with the cross-section of the annular cavity 13, leaving only a small gap, and the center of ...

Embodiment 2

[0027] Embodiment 2: This kind of closed grease damping damping clutch, the center of the annular cavity 13 is provided with three stoppers connected by riveting symmetrically, and there is a sector in the middle of the stoppers that can accommodate the outer edge of the spline keyboard hub 6. The gap through which the protrusion passes, and the middle of the stopper is consistent with the thickness of the outer side of the fan-shaped protrusion on the figure keypad hub 6, and only a small amount of gap is reserved. All the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com