Unit curtain wall with new structural upper transverse frame assembly

A technology of unit curtain wall and horizontal frame, applied in the direction of building components, walls, building structures, etc., can solve the problem of high material cost, achieve the effects of eliminating cold bridges, reducing end-cutting procedures, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

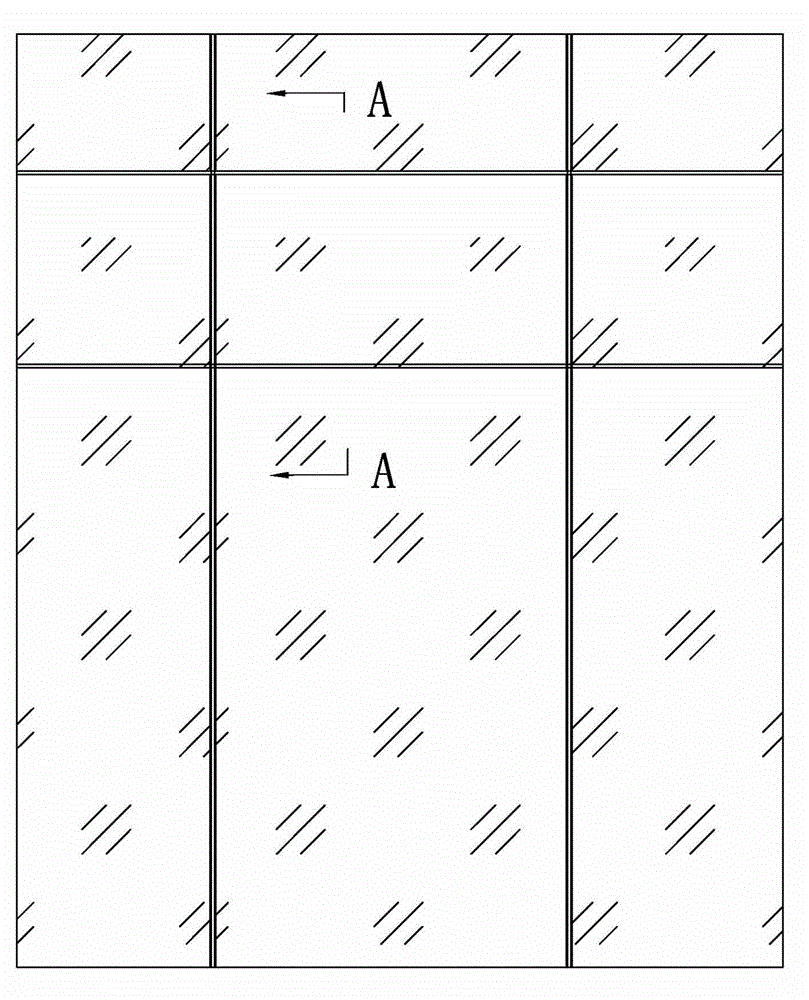

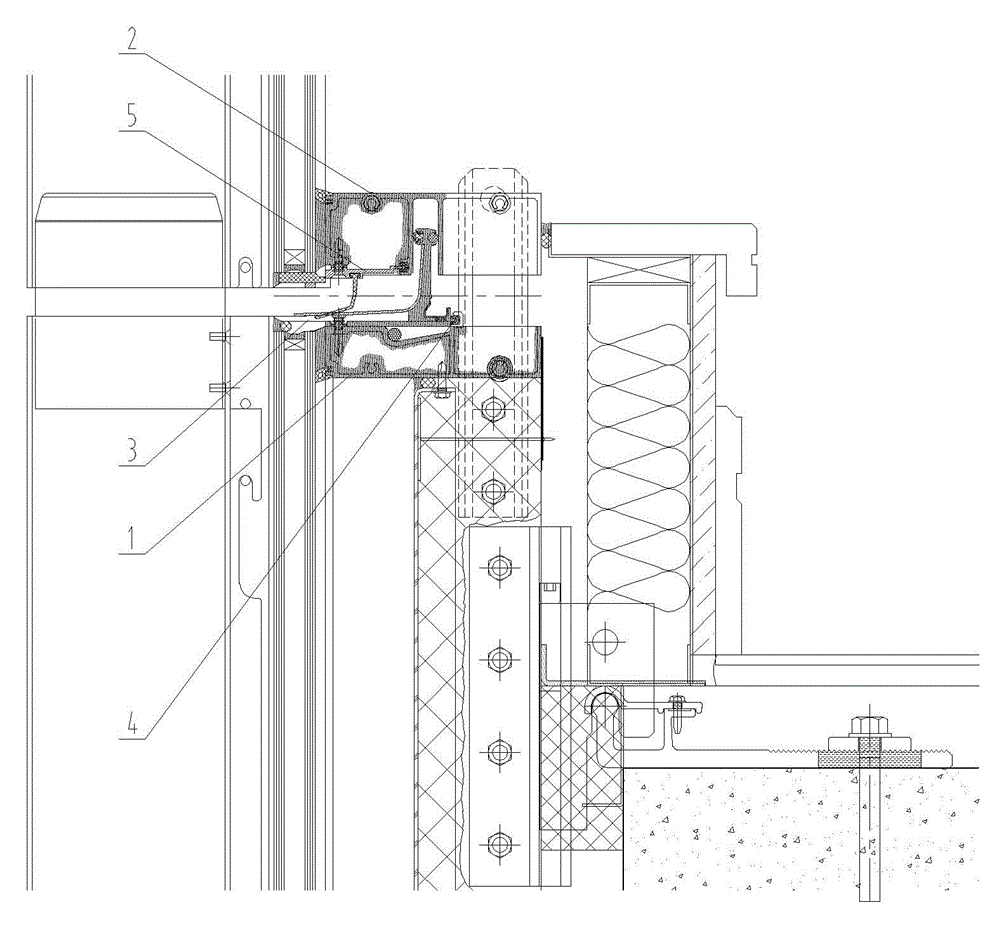

[0010] Combine below figure 1 and figure 2 The specific structure of the present invention will be further described.

[0011] This kind of unit curtain wall adopting the new structure horizontal frame assembly is composed of the unit upper horizontal frame 1, the unit lower horizontal frame 2, the unit upper horizontal frame assembly 3, and the unit bottom frame 5, which are not processed by the end cutting process. The unit upper horizontal frame assembly 3 and the unit upper horizontal frame 1 are connected through the heat insulating strip 4, so that the cold bridge between the unit upper horizontal frame assembly 3 and the unit upper horizontal frame 1 is eliminated.

[0012] During the production and assembly of the unit curtain wall, it should be noted that when the plug-in of the upper horizontal frame component 3 of the unit that has not been processed by the end cutting process is connected with the upper horizontal frame 1 of the unit, the stainless steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com