Composite adiabatic insulation board

A composite, thermal insulation board technology, used in thermal insulation, building components, fire protection, etc., to ensure energy saving, ensure thermal insulation and energy saving, and eliminate cold bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

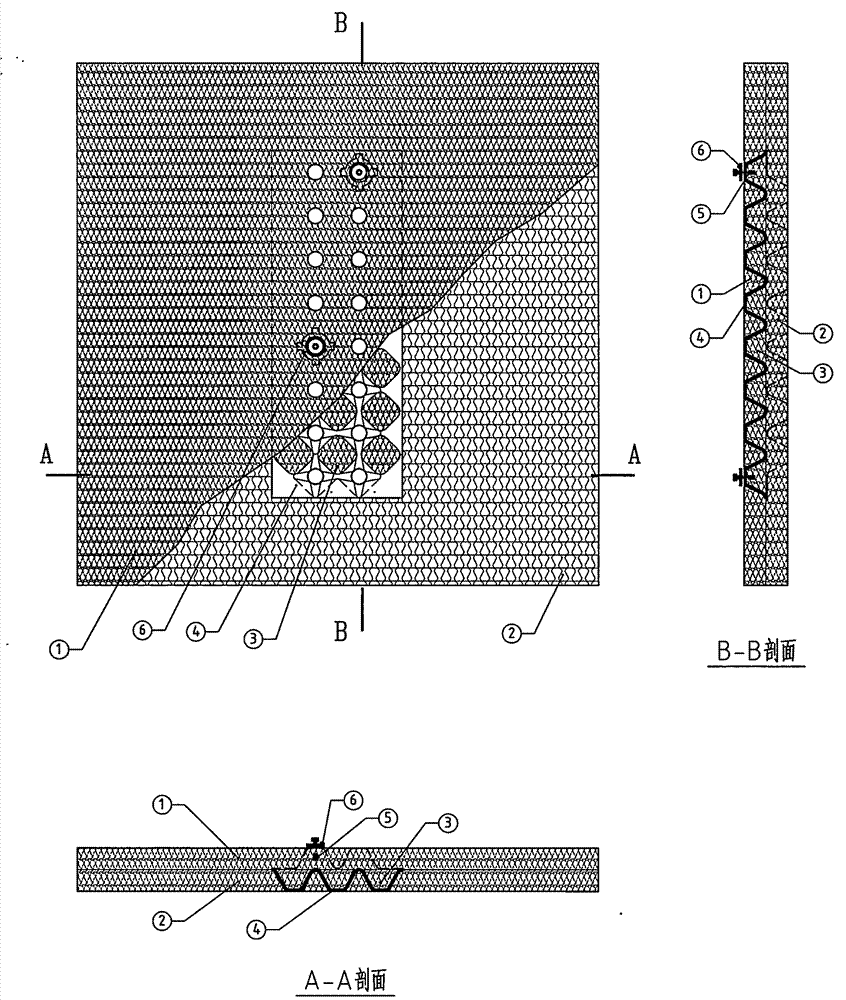

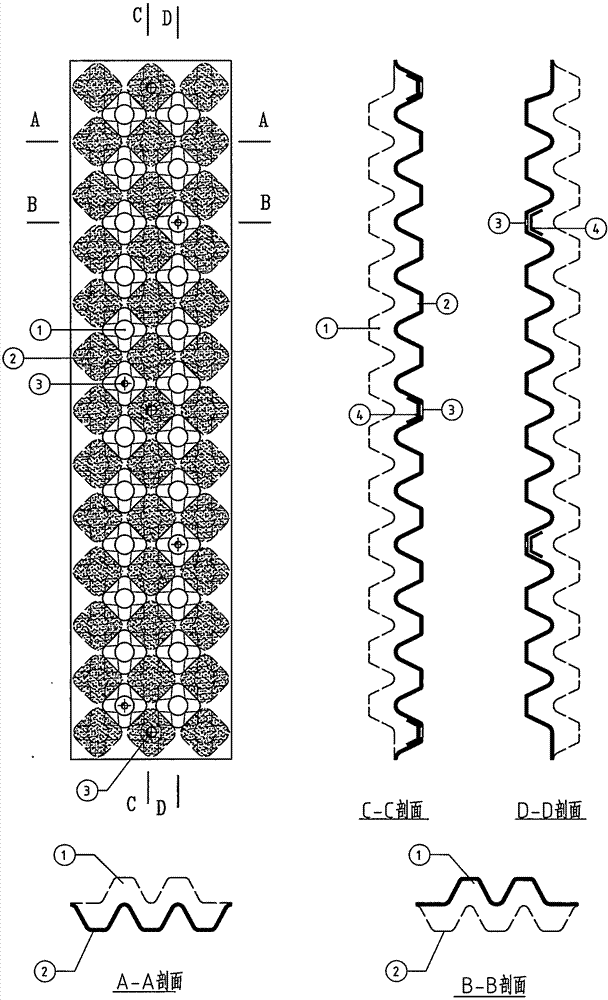

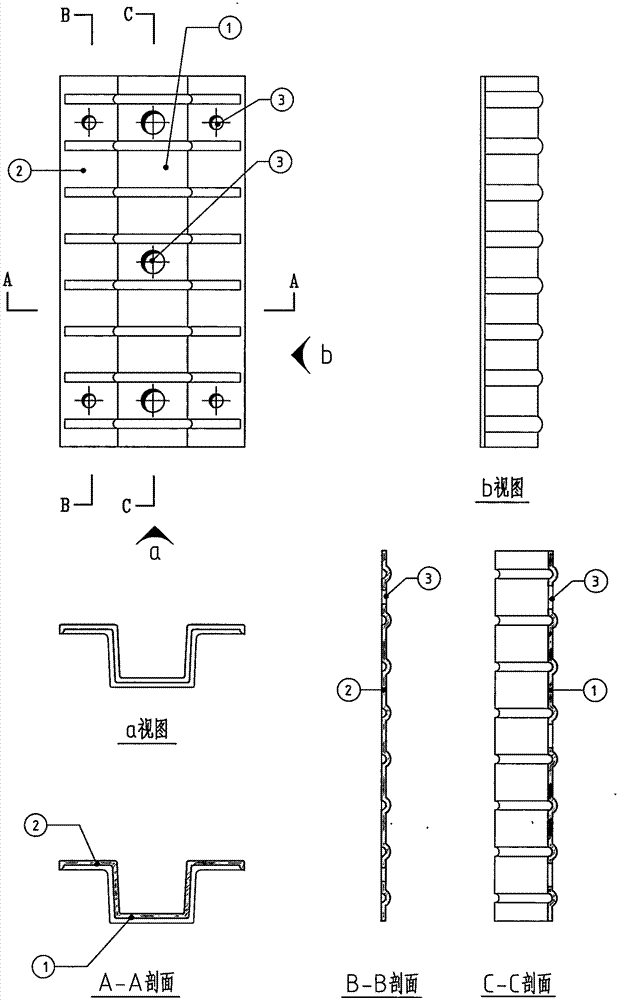

[0053] The invention scientifically and rationally utilizes the characteristics of different materials in terms of thermal insulation performance, mechanical performance, fireproof performance and thermal insulation performance, and combines the thermal insulation material and the thermal insulation component into a composite thermal insulation board. In the specific implementation, the first is the material selection and manufacture of the thermal insulation components, and then the selection and post-processing of the thermal insulation material.

[0054] 5.1. Manufacture of thermal insulation components and selected materials:

[0055] (1). The component is made of high-strength, refractory fiber material, which is impregnated with thermosetting resin and then molded at high temperature.

[0056] (2). The fiber material of the component is selected from the existing high-strength and fire-resistant glass fiber products, carbon fiber products, basalt fiber products, etc.; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com