Fire-proof adiabatic concrete sandwich wallboard and mounting method thereof

A concrete and sandwich wall technology, applied in the building exterior wall and construction field, can solve the problem of the fire resistance limit being difficult to meet the design standards, and achieve the effects of preventing direct flame burning, eliminating cold bridges, and improving fire performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

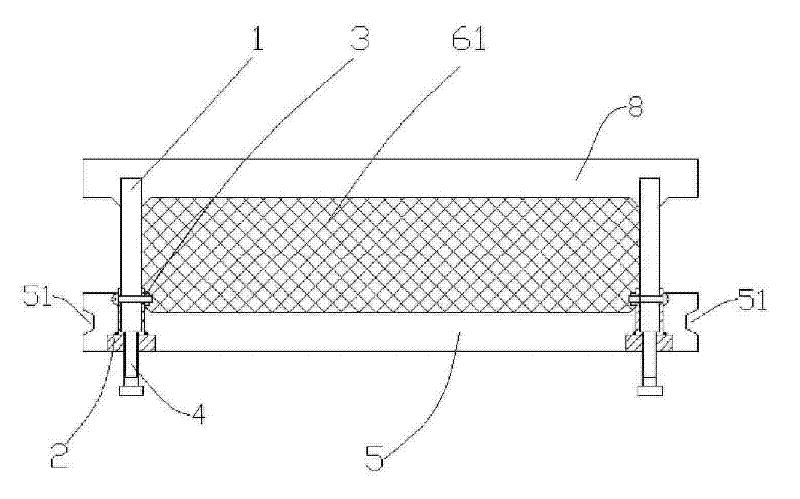

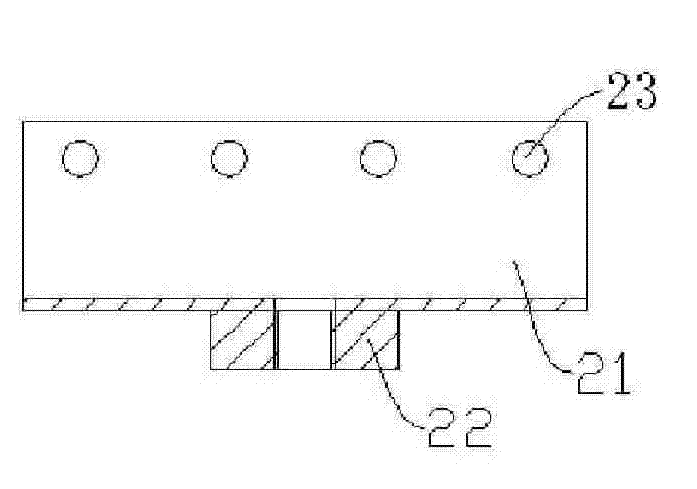

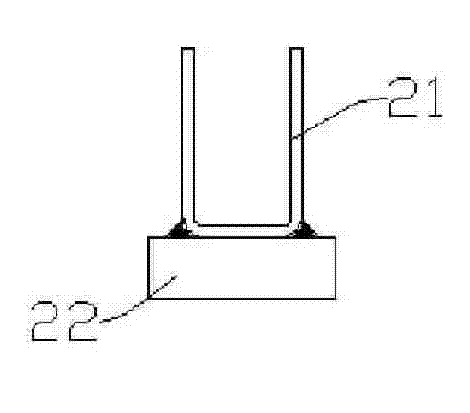

[0024] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 as shown in:

[0025] Taking the strip-shaped refractory and heat-insulating concrete sandwich wallboard as an example, the present invention includes a concrete inner panel 5 and a concrete outer panel 8, and the two sides in the width direction of the concrete inner panel 5 and the concrete outer panel 8 are provided with concrete The anchor 1 of the inner panel 5 and the concrete outer panel 8, the base material of the anchor in this embodiment is a plywood strip. An epoxy resin adhesive coating is provided on the surface of the plywood slats, and evenly distributed sand grains are arranged on the edges of the long sides of the plywood slats. The epoxy resin adhesive coating is carbon fiber impregnated adhesive. A thermal insulation core material 61 is arranged between the concrete inner panel 5 and the concrete outer panel 8, and the thermal insulation core material 61 is selected to...

Embodiment 2

[0033] Example 2, such as Image 6 as shown in:

[0034] In this embodiment, a reinforcing anchor 7 for strengthening the tension between the inner concrete panel 5 and the outer concrete panel 8 is provided between the inner concrete panel 5 and the outer concrete panel 8 . In addition, a fire-proof and heat-insulating layer 62 is provided between the heat-insulating core material 61 and the concrete inner panel. The thickness of the heat insulating core material 61 is 30mm. Suitable for use in southern regions. The insulating core material 61 is foamed plastics, such as EPS, XPS, PU and other foamed plastics.

[0035] When making the fire-resistant and heat-insulating concrete sandwich wallboard of the present invention, the inner panel 5 of fine stone concrete is poured on the mold bottom plate, and after being flattened and compacted, the reinforced anchor 7 is placed, and the reinforced anchor 7 and the The material of the anchor 1 is the same, but the embedded part 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com