Water-saving cover structure of toilet flushed by high-pressure water in closed manner

A technology of high-pressure water and cover structure, which is applied in the field of water-saving sanitary ware, can solve the problems of non-elimination, unclean flushing, inconvenience, etc., and achieve the effect of reliable use, good flushing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

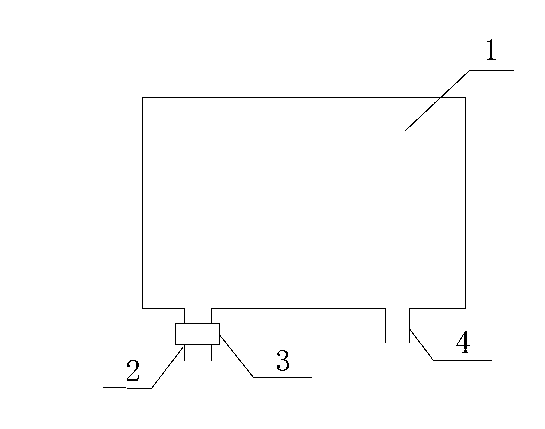

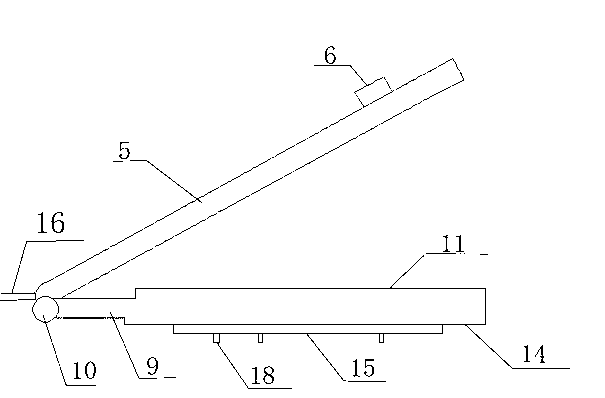

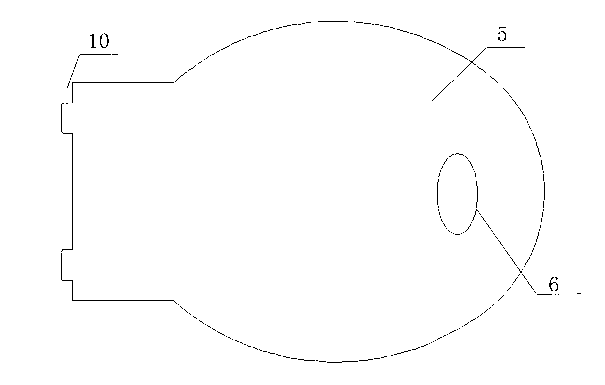

[0019] High-pressure water airtight flushing toilet water-saving cover structure, including toilet bowl, cover body 5, switch 6, annular ring 9, shaft 10, annular flushing pipe 15, water inlet pipe 16, water outlet pipe 17 and water nozzle 18, and the cover body 5 matches with the annular ring 9, and is arranged on the toilet bowl, and the toilet bowl forms a closed cavity; the shaft 10 is fixed on the toilet bowl, and the cover body 5 and the annular ring 9 are installed on the shaft 10 to rotate together; There is a handle, the handle is provided with a switch 6, and the toilet bowl is provided with a water inlet pipe 16 and an outlet pipe 17 near the shaft; The annular flushing pipe 15 is connected successively, and the annular flushing pipe 15 is provided with a downward water spray nozzle 18; the path of the flushing water is the water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com