Device and method for directionally growing fluoride single crystal via lifting small-gradient thermal field

A technology of directional growth and fluoride, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as solid-liquid interface shape, low success rate, waste, etc., to reduce internal defects of crystals and avoid massive The effect of spillover and crystal quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

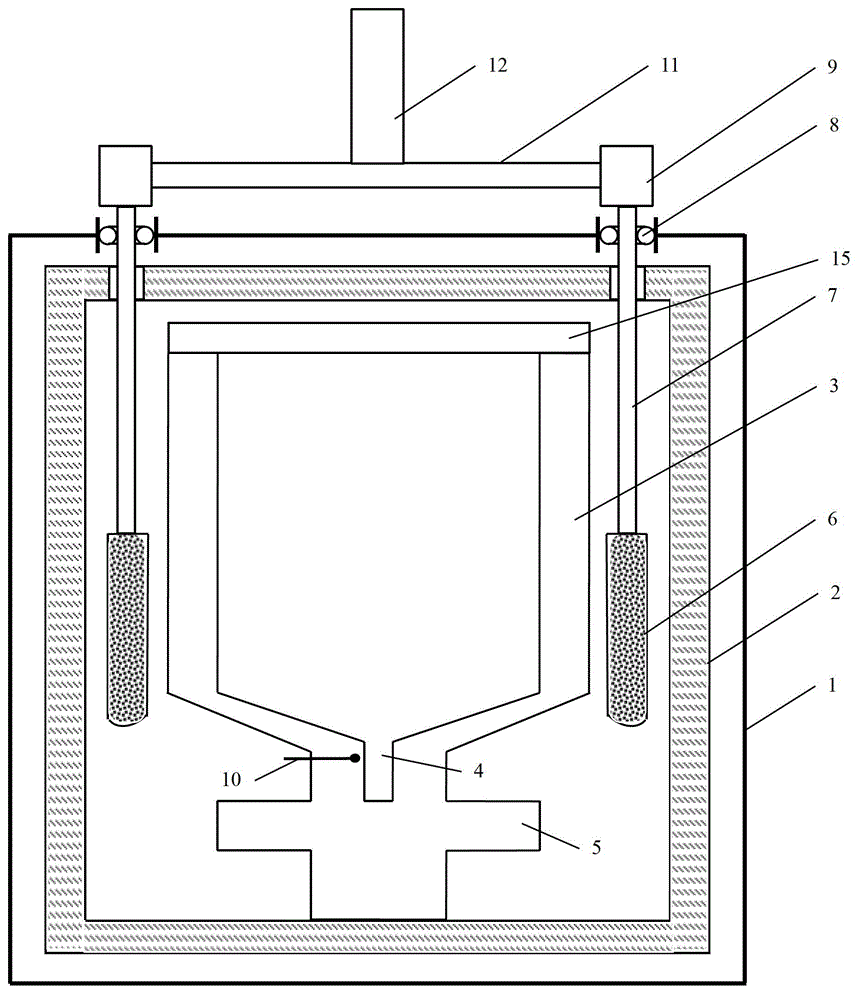

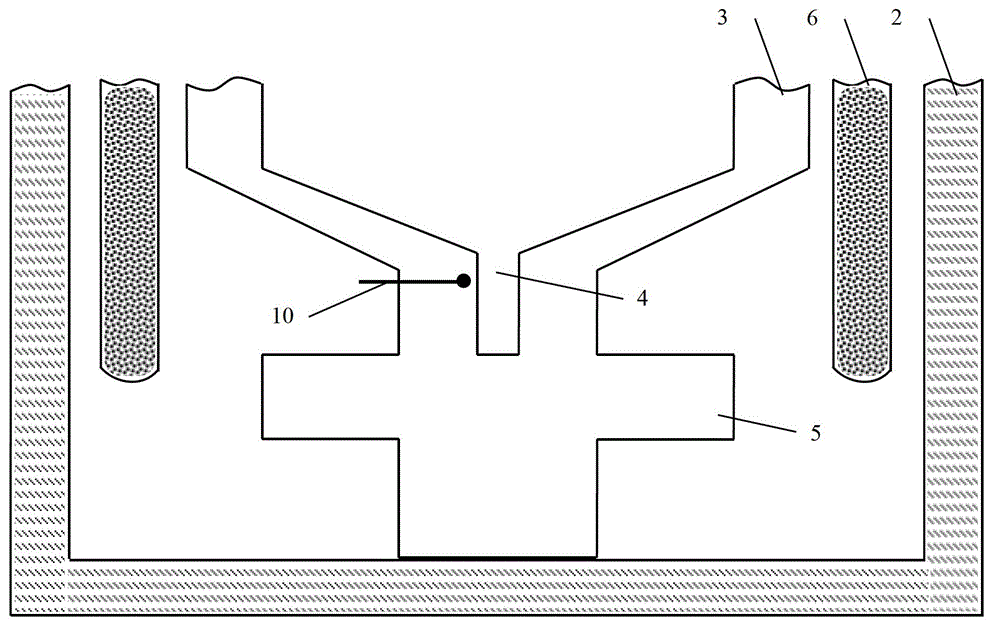

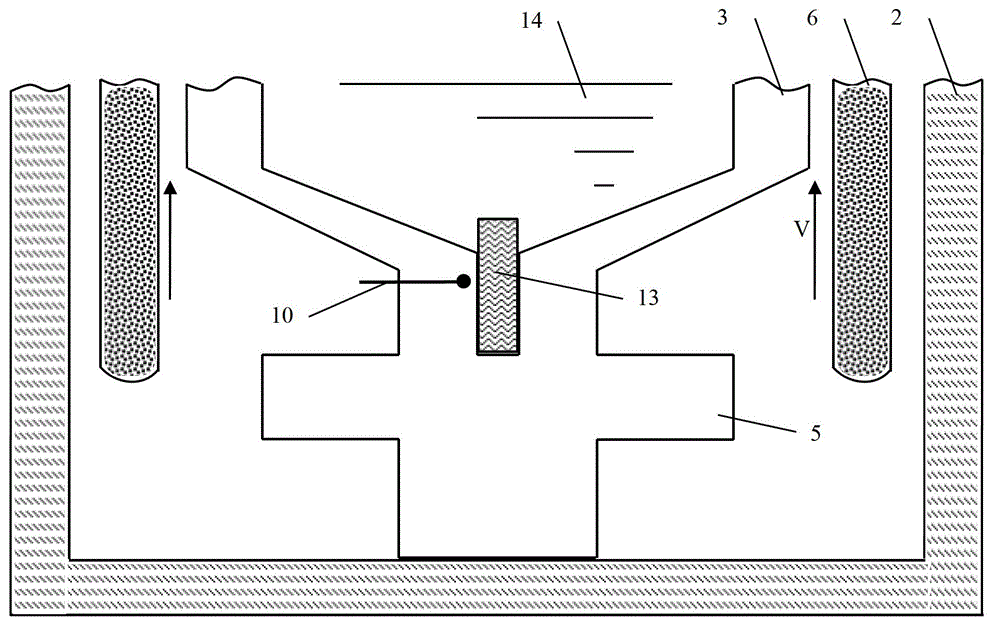

[0012] In the device for directional growth of fluoride single crystal with small gradient temperature field rising in the present invention, the inner periphery of the vacuum chamber 1 is a thermal insulation cover 2, the material of the thermal insulation cover 2 is composite carbon fiber, the crucible 3 is located in the center of the thermal insulation cover 2, and the crucible 3 Add graphite material crucible cover 15 to prevent the heat loss of the growth material melt and prevent the growth material from volatilizing, such as figure 1 Shown; in the center of the bottom of the crucible 3 there is a crystal cylinder 4, the crucible base 5 is below the crystal cylinder 4, and the crucible base 5 is made of graphite; several heating bodies 6 are suspended around the side walls of the crucible 3 at equal heights, and the upper end of the heating body 6 Connect the water-cooled electrode rod 7, the electrode rod 7 first passes through the top of the insulation cover 2 and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com