Anti-aging cushion rubber rope

A buffer rubber and anti-aging technology, applied in the field of rubber, can solve the problems of buffer equipment hidden dangers, buffer rubber ropes are prone to aging and cracking, etc., and achieve the effects of increasing life, reducing the probability of cracks, and improving tensile fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Its raw material ratio is: 100 parts of 1# natural rubber, 1 part of sulfur, TT accelerator (Chinese name: tetramethylthiuram disulfide, molecular formula: C6H12N2S4) 0.2 part, CZ accelerator (Chinese name : N-cyclohexyl-2-benzothiazole sulfenamide, molecular formula: C13H16N2S2) 0.5 parts, zinc oxide 4 parts, stearic acid 0.9 parts, paraffin wax 0.9 parts, D antioxidant (Chinese name: N-phenyl- 2-naphthylamine, molecular formula: C16H13N) 1 part, anti-aging agent 4010NA (Chinese name: N-isopropyl-N'-phenyl-p-phenylenediamine, molecular formula: C15H18N2) 0.4 part.

[0024] The specific production steps are as follows:

[0025] Compound production

[0026] ⑴ Weigh various ingredients according to the specific formula ratio;

[0027] (2) Take 100 parts of 1# natural rubber and add it to the rubber mixing machine. After mixing for 2 minutes, add 1 part of sulfur, 4 parts of zinc oxide, 1 part of D antioxidant, and 0.4 part of 4010NA antioxidant and mix well...

Embodiment 2

[0036] The production process of embodiment 2 is identical with embodiment 1, and difference is that the rubber material component ratio is different, and the rubber material composition of embodiment 2 is calculated as follows by component: 1# natural rubber 110 parts, sulfur 2 parts, accelerator TT (Chinese name: tetramethylthiuram disulfide, molecular formula: C6H12N2S4) 0.25 parts, accelerator CZ (Chinese name: N-cyclohexyl-2-benzothiazole sulfenamide, molecular formula: C13H16N2S2) 0.55 parts, oxidation 5 parts of zinc, 1 part of stearic acid, 1 part of paraffin, anti-aging agent D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C16H13N) 1.5 parts, anti-aging agent 4010NA (Chinese name: N-isopropyl -N'-phenyl-p-phenylenediamine, molecular formula: C15H18N2) 0.5 parts.

Embodiment 3

[0037] The production process of embodiment 3 is identical with embodiment 1, and difference is that the ratio of rubber material components is different, and the rubber material composition of embodiment 3 is counted as follows by component: 120 parts of 1# natural rubber, 3 parts of sulfur, accelerator TT (Chinese name: tetramethylthiuram disulfide, molecular formula: C6H12N2S4) 0.3 parts, accelerator CZ (Chinese name: N-cyclohexyl-2-benzothiazole sulfenamide, molecular formula: C13H16N2S2) 0.6 parts, oxidation 6 parts of zinc, 1.1 parts of stearic acid, 1.1 parts of paraffin, 2 parts of anti-aging agent D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C16H13N), 2 parts of anti-aging agent 4010NA (Chinese name: N-isopropyl -N'-phenyl-p-phenylenediamine, molecular formula: C15H18N2) 0.6 parts.

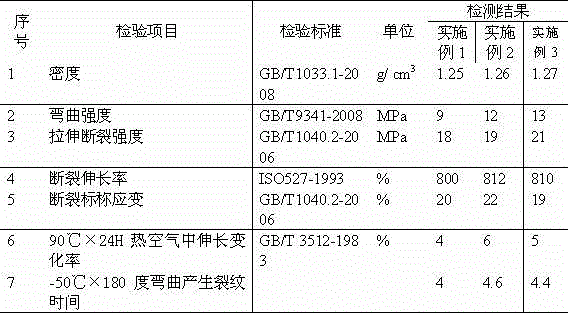

[0038] Performance comparison of three kinds of embodiments

[0039]

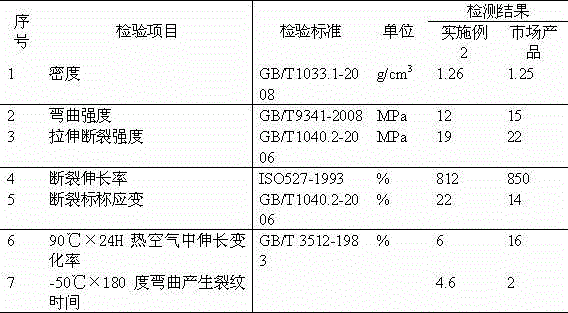

[0040] Embodiment 2 formula compares with the current market product produced by original formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com