Process for extracting mannan from beer yeast powder

A technology of brewer's yeast powder and mannan, which is applied in the field of bioengineering, can solve the problems of low product purity and environmental pollution, and achieves the effects of high physical and chemical stability, reduced production cost and good enrichment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

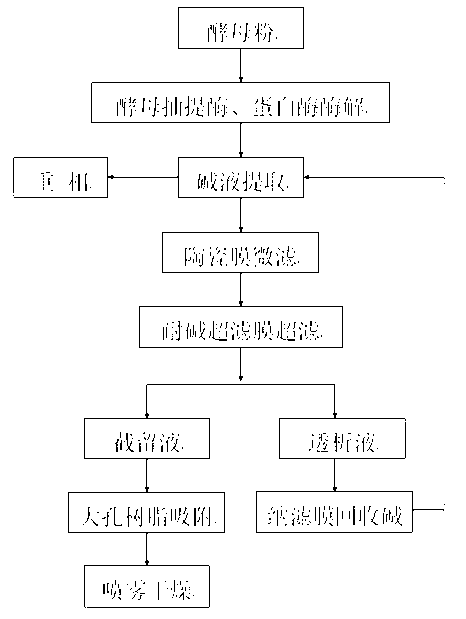

Method used

Image

Examples

Embodiment 1

[0045] A process for extracting mannan in brewer's yeast powder, using brewer's yeast powder as a substrate, comprising the steps of:

[0046] (1) Enzymolysis and alkali extraction: Weigh 48Kg of the substrate brewer’s yeast powder, add 352Kg of water, stir and mix well, adjust the pH value to 6 with glacial acetic acid solution with a mass fraction of 5%, add yeast to extract at a temperature of 60°C Enzyme hydrolysis with 2Kg of enzyme and 2Kg of neutral protease for 2 hours to obtain an enzymolysis solution; then add 8.08 Kg of sodium hydroxide solid to the enzymolysis solution and stir at 65°C for 1 hour to obtain an extract;

[0047] (2) Microfiltration: The extract obtained in step (1) is separated into a heavy phase and a light phase by a centrifuge, and the heavy phase is then filtered by a filter press to separate the slag and the filtrate, and the filtrate is mixed with the light phase Finally, the ceramic membrane microfiltration equipment with a pore size of 0.2 μm...

Embodiment 2

[0053] A process for extracting mannan in brewer's yeast powder, using brewer's yeast powder as a substrate, comprising the steps of:

[0054] (1) Enzymolysis and alkali extraction: Weigh 60Kg of the substrate brewer’s yeast powder, add 340Kg of water, stir and mix well, adjust the pH value to 5.5 with glacial acetic acid solution with a mass fraction of 20%, and add yeast to extract at a temperature of 55°C 0.4Kg of enzyme and 0.4Kg of alkaline protease were used for enzymolysis for 8 hours to obtain an enzymolysis solution; then 24.05 Kg of potassium hydroxide solid was added to the enzymolysis solution, and stirred at 60°C for 2 hours to obtain an extract;

[0055] (2) Microfiltration: The extract obtained in step (1) is separated into a heavy phase and a light phase by a centrifuge, and the heavy phase is then filtered by a filter press to separate the slag and the filtrate, and the filtrate is mixed with the light phase Finally, the ceramic membrane microfiltration equipm...

Embodiment 3

[0061] A process for extracting mannan in brewer's yeast powder, using brewer's yeast powder as a substrate, comprising the steps of:

[0062] (1) Enzyme hydrolysis and alkali extraction: Weigh 140Kg of the substrate beer yeast powder, add 860Kg of water, stir and mix well, adjust the pH value to 7.5 with glacial acetic acid solution with a mass fraction of 10%, and add yeast to extract at a temperature of 57°C 2Kg of enzyme and 4Kg of alkaline protease were subjected to enzymolysis for 6 hours to obtain an enzymolysis solution; then 100.6 Kg of sodium hydroxide solid was added to the enzymolysis solution, and stirred at 75°C for 0.5 hours to obtain an extract;

[0063] (2) Microfiltration: The extract obtained in step (1) is separated into a heavy phase and a light phase by a centrifuge, and the heavy phase is then filtered by a filter press to separate the slag and the filtrate, and the filtrate is mixed with the light phase Finally, the ceramic membrane microfiltration equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com