Molecular sieve catalyst and preparation method thereof

A molecular sieve and catalyst technology, applied in the field of molecular sieve catalyst and its preparation, can solve the problems of complex production process of the molecular sieve catalyst, and achieve the effect of solving the difficulty of slurry grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

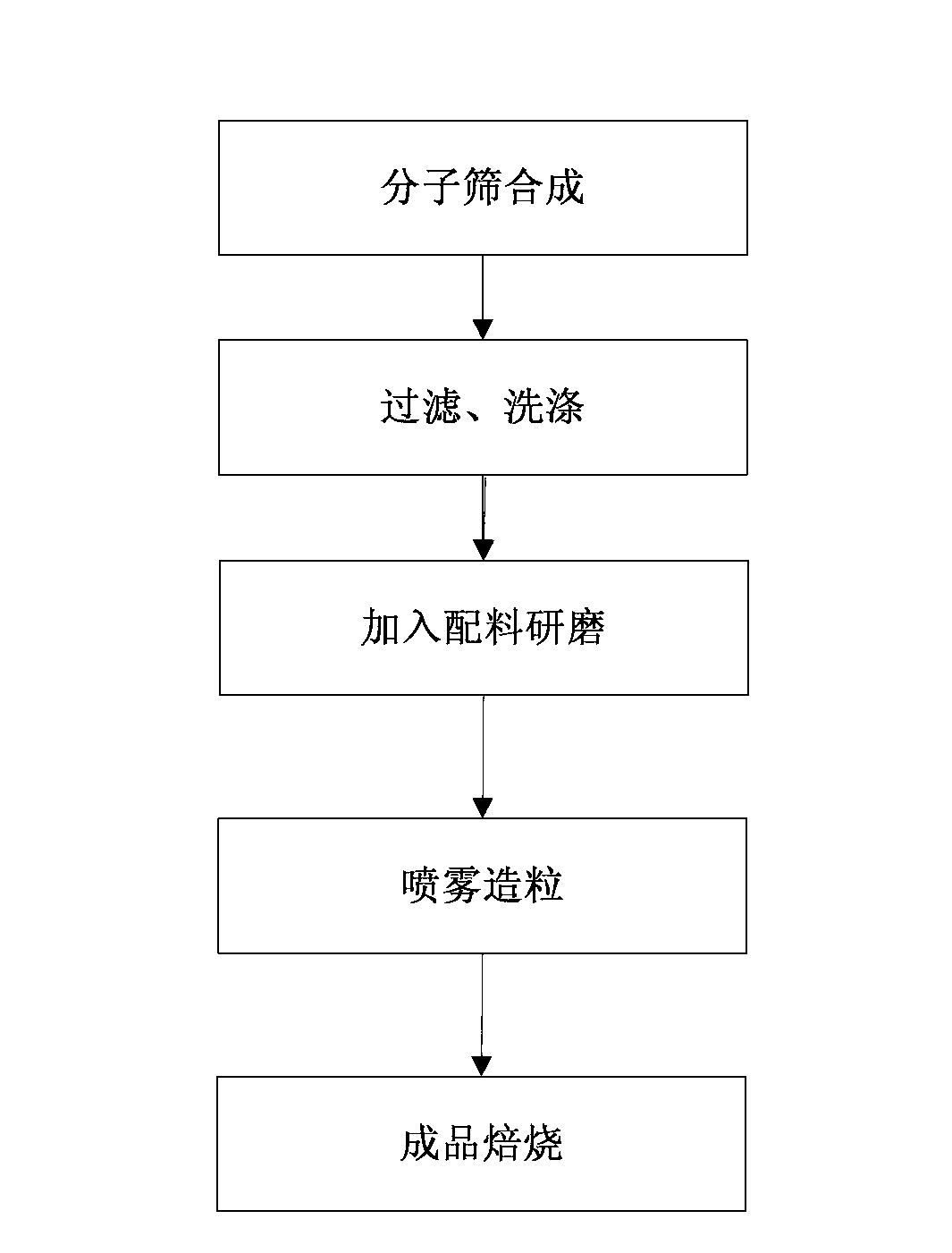

[0018] According to a typical embodiment of the present invention, such as figure 2 As shown, the preparation method of the molecular sieve catalyst includes the following steps: S1, using aluminum source, silicon source, phosphorus source and template as raw materials to prepare the molecular sieve precursor solution by hydrothermal method; S2, directly mixing the molecular sieve precursor solution with water, grinding, Obtaining molecular sieve slurry, adding ingredients to the molecular sieve slurry and continuing to grind for 2-4 hours to obtain a semi-finished molecular sieve catalyst; and S3, granulating, drying and roasting the semi-finished molecular sieve catalyst to obtain a molecular sieve catalyst.

[0019] Washing and filtering the prepared molecular sieve precursor solution is directly mixed with water for grinding to prepare molecular sieve slurry. Compared with the production process in the prior art, the steps of washing and filtering the molecular sieve precu...

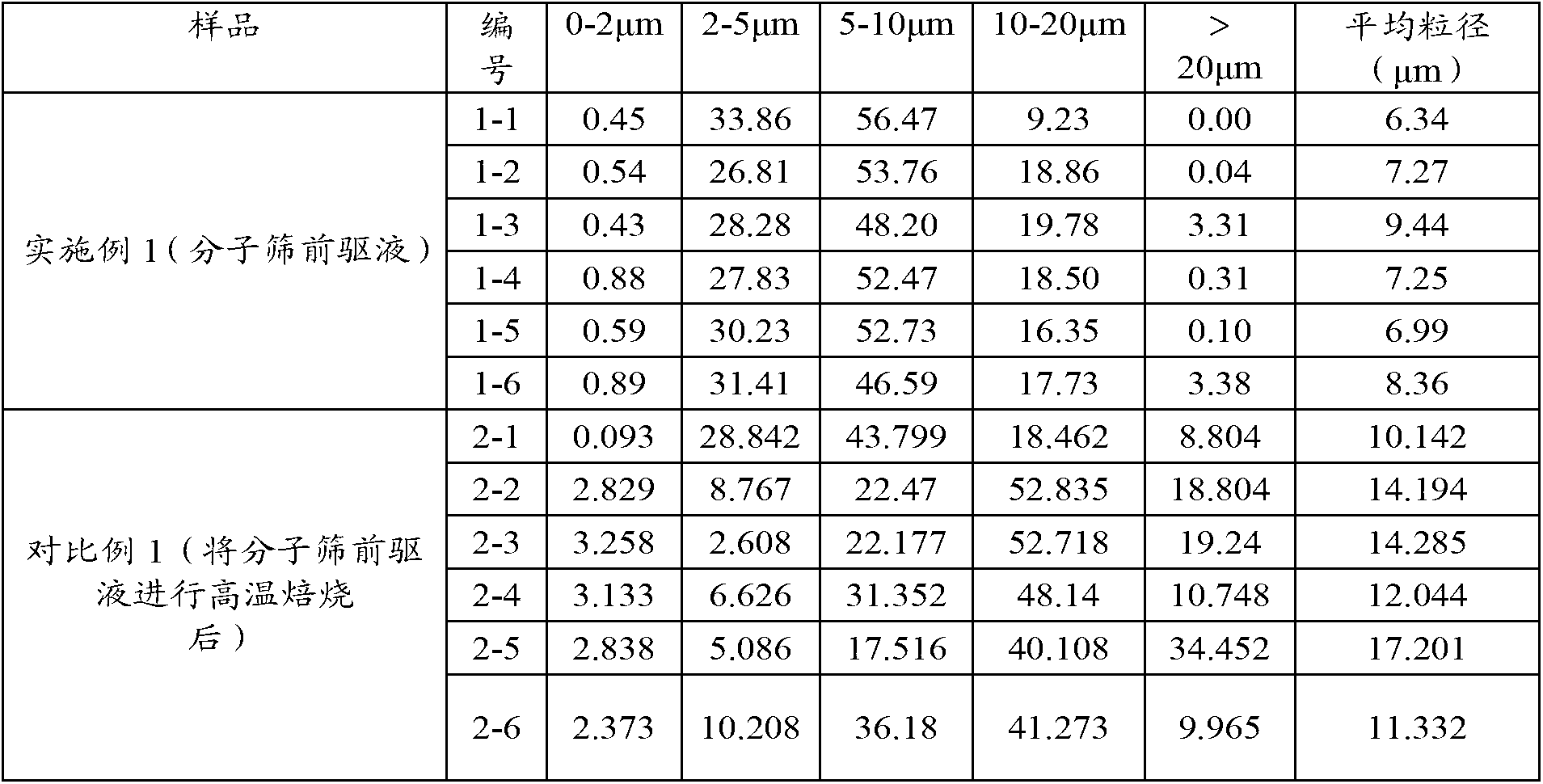

Embodiment 1

[0027] Triethylamine is used as template, silica sol, pseudoboehmite, phosphoric acid and water are used as raw materials respectively, and the raw materials are weighed according to the molar ratio of template: Si:A1:P:H2O=3.0:0.5:1.0:1.5:30 , mix, transfer the obtained mixture into an autoclave, and react at 200° C. and autogenous pressure for 48 hours to obtain a molecular sieve precursor. Wherein the weight percentage of the molecular sieve particles with a particle diameter of 2-10 μm in the molecular sieve precursor liquid accounts for 90%. After the crystallization, the molecular sieve precursor solution is subjected to three-stage washing and filtration using a belt suction filter to remove impurity ions adsorbed on the surface of the molecular sieve. The filtered and washed molecular sieve is not dried and roasted, but added to a batching tank filled with water, mixed with water, ground and fully beaten to obtain a molecular sieve slurry, and pseudo-boehmite is added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com