Wheel rim driving system

A wheel-side drive and wheel technology, which is applied in the direction of power plant, motion deposition, vehicle parts, etc., can solve the problem of large impact on the vertical, longitudinal and lateral performance of the vehicle, high requirements for installation and layout space, and space utilization of the vehicle. Low-level problems, to achieve the effect of low layout space requirements, good sealing performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

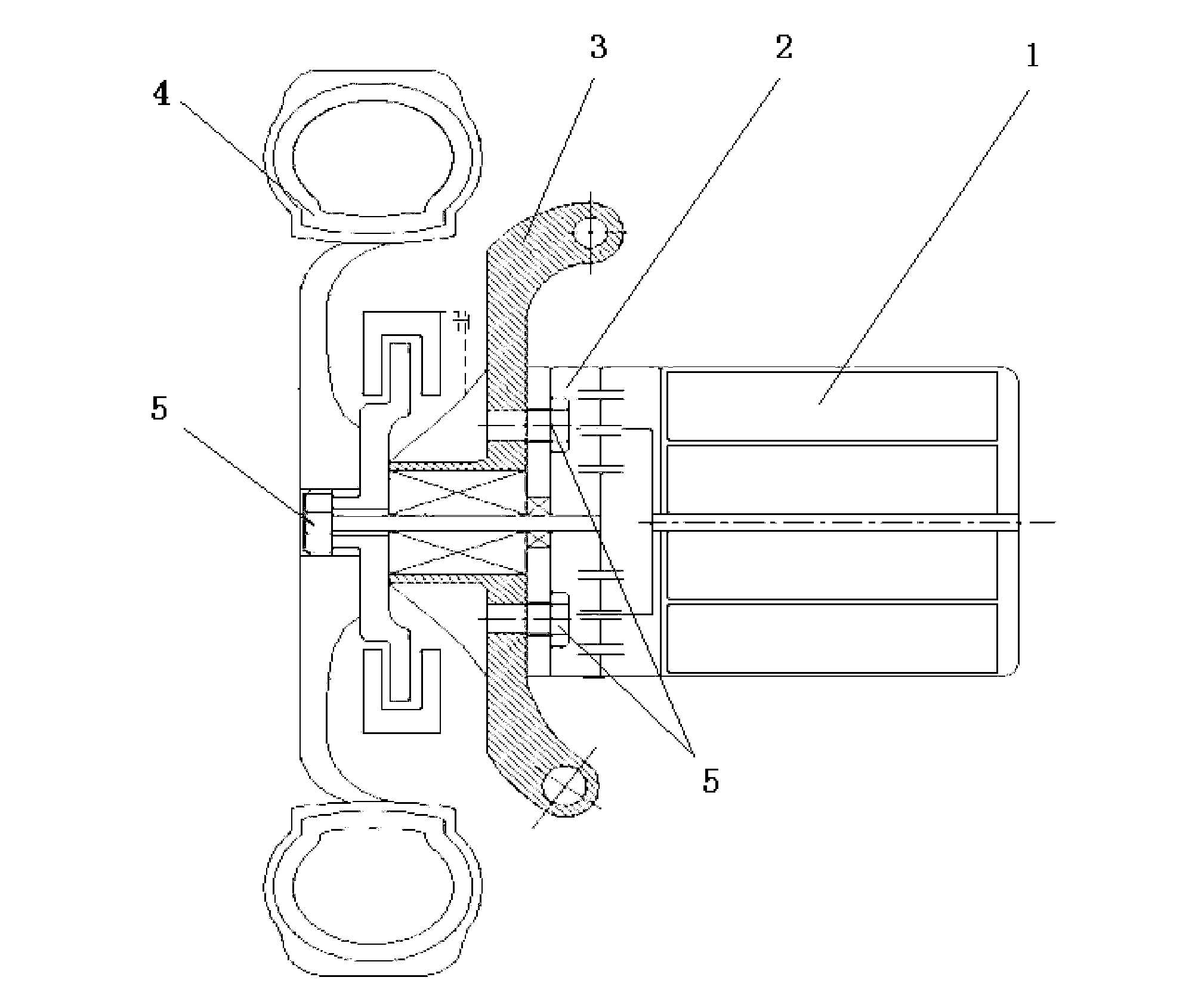

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a wheel side drive system, located inside the wheel hub, the wheel side drive system includes a motor 1 and a planetary reducer 2 fixedly arranged on the suspension, the outer shell of the motor 1 It is integrally connected with the outer ring gear of the planetary reducer 2 . The output shaft of the motor 1 , the output shaft of the planetary reducer 2 and the drive shaft of the wheel 4 are all located on the same axis. The driving force of the motor 1 is first transmitted to the wheels 4 through the planetary reducer 2 .

[0024] The outer casing of the motor 1 of the present invention is connected with the outer ring gear of the planetary reducer 2 as a whole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com