Lathe

A technology of machine tools and servo motors, which is applied in the field of ordinary machine tools, can solve the problems of difficult processing of complex and high-precision workpieces, impossible automatic processing, and difficult guarantee of precision, so as to improve precision, save money, and realize automatic processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

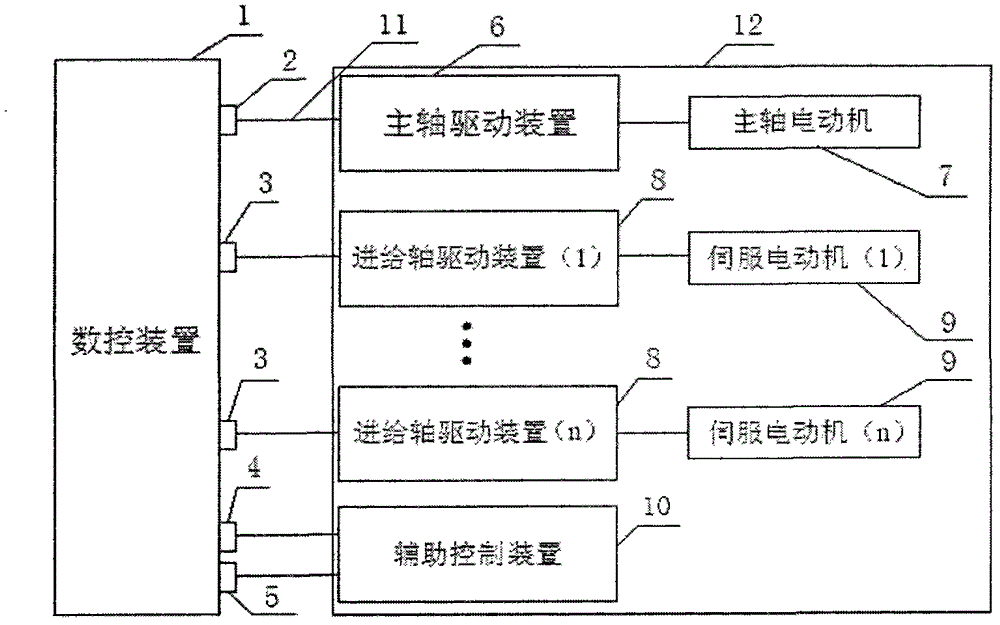

[0012] As shown in the embodiment of the accompanying drawings: on the common machine tool 12, the main shaft driving device 6 is connected with the provided main shaft motor 7, and several feed shaft driving devices 8 are connected with the corresponding servo motor 9; the common machine tool 12 is provided with an auxiliary control device 10. The spindle drive device 6, several feed axis drive devices 8 and auxiliary control device 10 on the above-mentioned common machine tool 12 are respectively connected to the numerical control device 1 through data lines 11. The spindle driving device 6 is connected to the spindle control interface 2 of the numerical control device 1 through a data line 11 . Several feed axis drive devices 8 are respectively connected to the feed axis control interface 3 of the numerical control device 1 through data lines 11 . The digital input interface 4 and the digital output interface 5 on the numerical control device 1 are respectively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com