Coalescing vacuum type oil cleaning device

A vacuum type, oil purification technology, applied in chemical instruments and methods, filtration separation, filtration circuits, etc., can solve problems such as low oil purification treatment efficiency, reduced oil lubrication and cooling effects, and damage to running parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

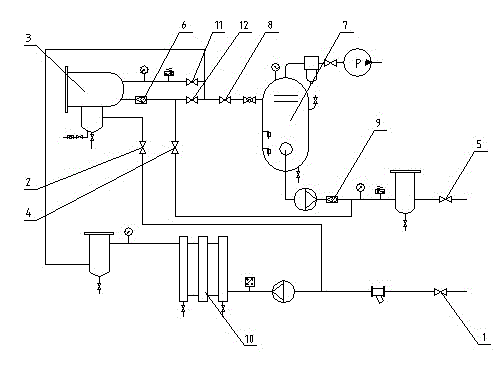

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] As shown in the figure, a coalescing vacuum oil purification device includes an oil inlet valve 1, a first switching valve 2, a coalescing separator 3, a second switching valve 4 and an oil outlet valve sequentially connected in series in the main oil circuit. Valve 5, a first check valve 6 is provided between the coalescence separator 3 and the second switching valve 4, and a vacuum separator assembly 7 is connected in parallel at both ends of the second switching valve 4, and the vacuum separator assembly 7, a third switching valve 8 is connected in series at the oil inlet, and a second check valve 9 is connected in series at the oil outlet of the vacuum separator assembly 7. A heater 10 is connected in parallel at both ends of the first switching valve 2 to the first check valve 6, and the oil outlet of the heater 10 is respectively provided with a fourth switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com