Flattening ophthalmotonometer

A technology of manometer and flat eye, which is applied in the field of contact applanation tonometry, and can solve the problems of measurement result error, measuring device shake, jitter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

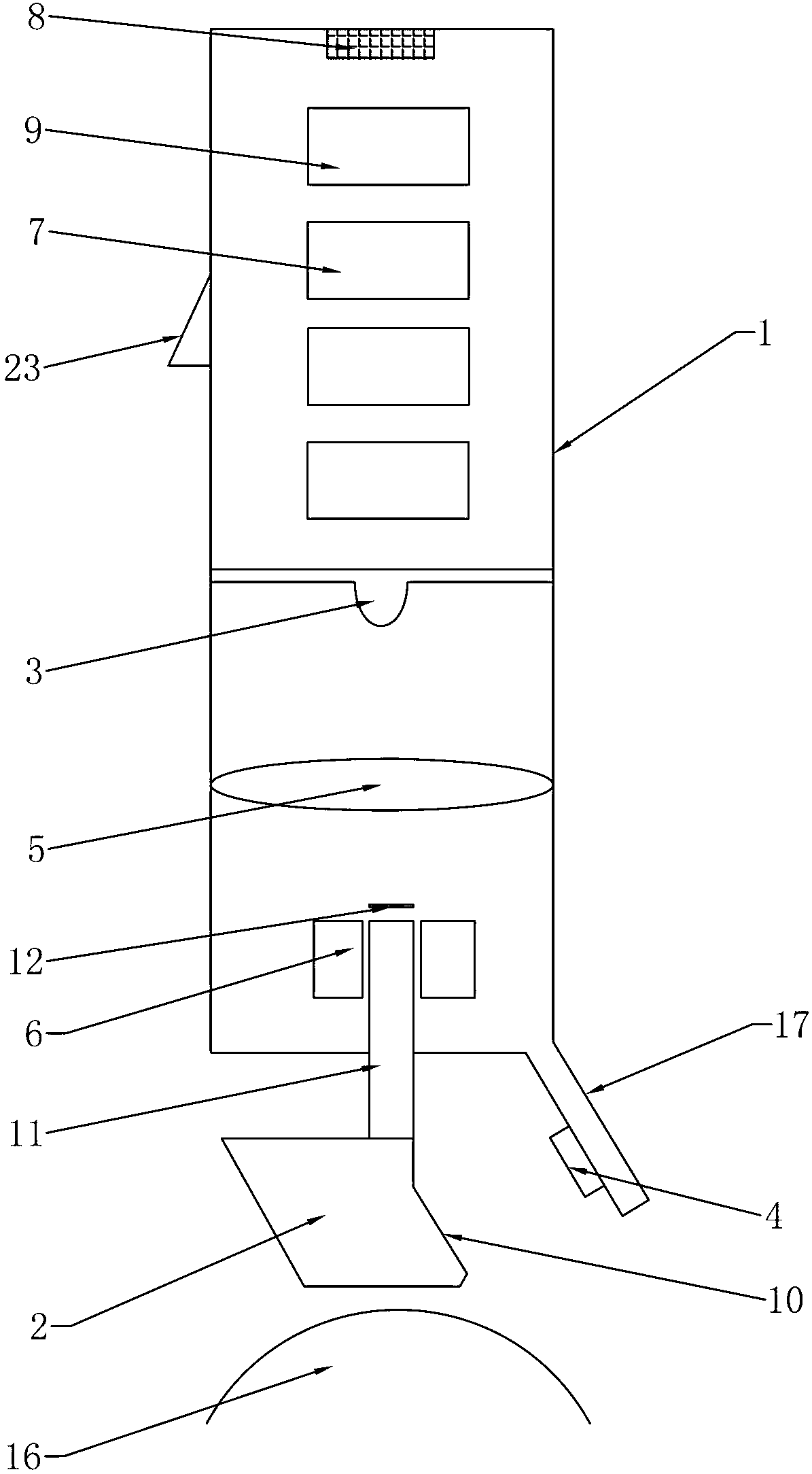

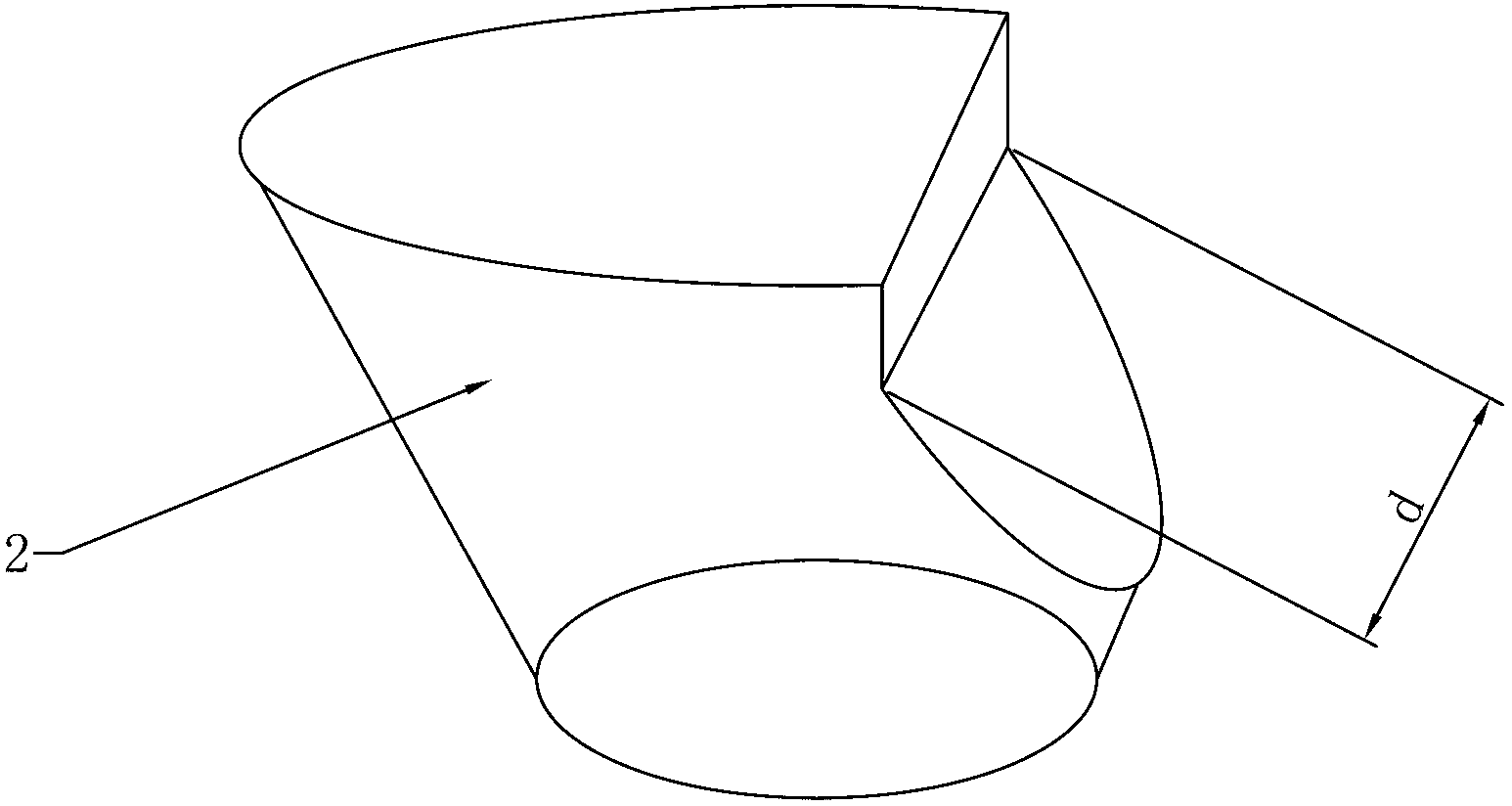

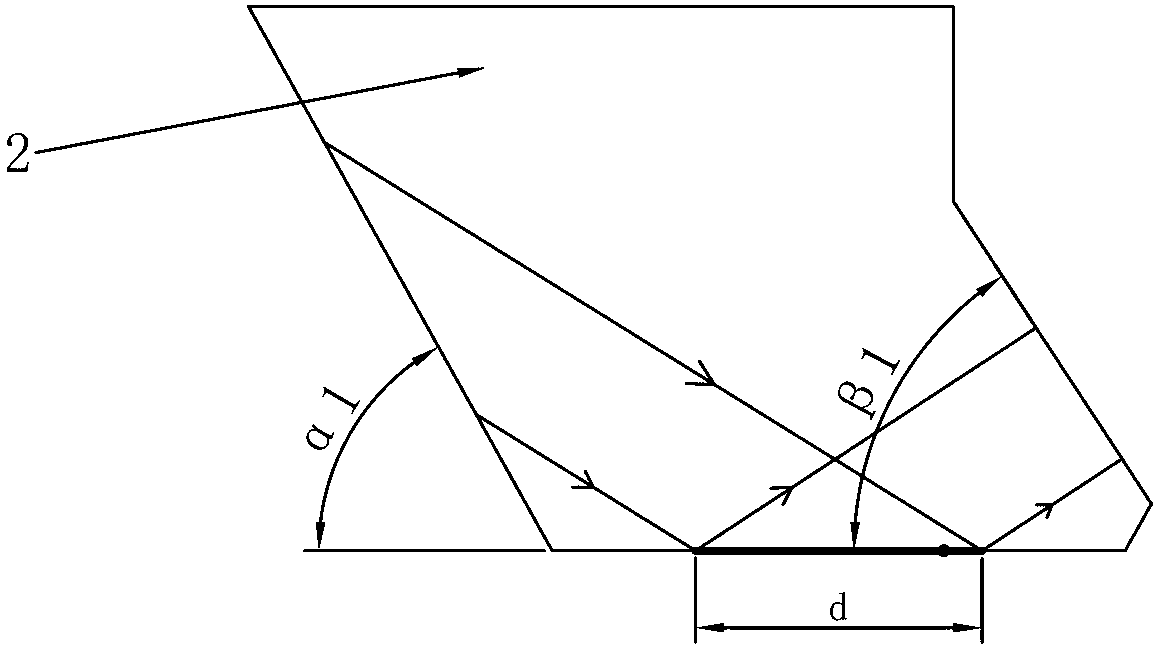

[0022] Such as figure 1 As shown, an applanation tonometer of the present invention includes a housing 1, a probe 2, a light source 3, a first image sensor 4, a convex lens 5, a green light filter 12, a force sensor 6, a microprocessor 7, and a power supply 8 and display memory 9 . combine figure 2 As shown, the probe 2 is generally in the shape of a truncated cone with a small bottom and a big top, and is located under the housing 1 . The probe 2 is made of transparent optical materials such as glass or resin. The conditions for the light to be fully emitted on the side and bottom of the probe 2 are related to the incident angle of the light and the material of the probe. When the incident angle is greater than or equal to the critical angle, the light is injected from the probe. When it reaches the side or lower surface of the probe, total reflection occurs. In this embodiment, K9 glass with a refractive index of 1.53 is used to make it. image 3 As shown, the cone angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com