Circular welding scar flattening machine for fire extinguisher bottle body

A technology for a fire extinguisher and a flattener, which is applied in the field of fire extinguisher production, can solve problems such as the influence of the aesthetics of the bottle body and the comfort of use, and achieve the effects of improving comfort and aesthetics, improving the support effect, and improving the convenience and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

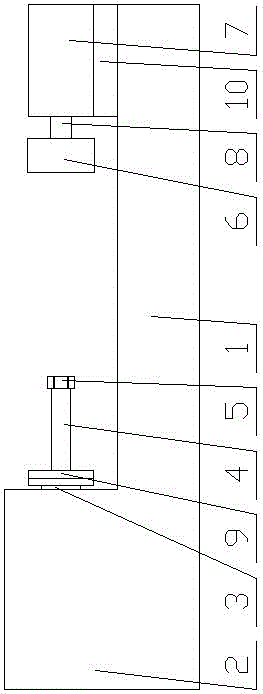

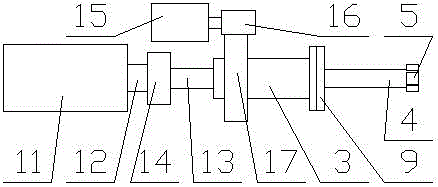

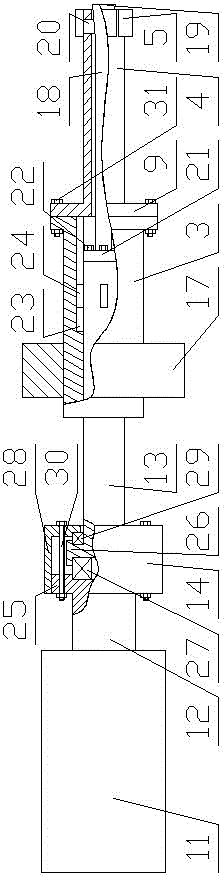

[0030] combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a bed body 1, and one end on the bed body 1 is provided with a headstock 2, and the end face of the other end of the headstock body 2 facing the bed body 1 stretches out a tension rod 4 of a fire extinguisher bottle, which is located at The side wall of the end of the expansion rod 4 is provided with an expansion block 5, and the expansion rod 4 is fixedly connected with the main shaft 3 in the headstock 2, and the main shaft 3 is driven by a motor 15, and the motor 15 is fixed In the headstock 2, the main shaft 3 is rotatably connected with the headstock 2; the other end of the bed body 1 relative to the headstock 2 is provided with a flattening device 6, and the flattening device 6 is fixed to the piston of the piston A7 At the end of the rod A8, the end of the flattening device 6 facing the expansion rod 4 is provided with a circular notch coaxial with the expansion rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com