Suckling pig creep feed mixed feed and preparation method thereof

A technology of compound feed and trough feed, applied in animal feed, animal feed, application, etc., can solve the problems of changing pig biological genetic genes, introducing pig virus diseases, low feed intake of suckling pigs, etc., and improving protein content. , The effect of increasing crude protein content and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

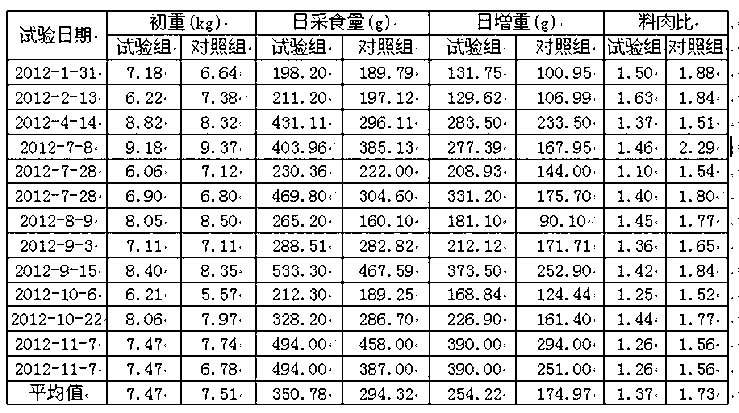

Examples

preparation example Construction

[0070] The preparation method of suckling pig teaching trough compound feed of the present invention includes the following steps:

[0071] Step 1: Put the raw materials of the premix, Sulfa, sulphuric acid and 0.076% of the zeolite powder into the V-shaped stainless steel mixer and mix evenly to obtain the initial mixture 1 for use;

[0072] Step 2: Put the raw material compound multivitamins for suckling pig, 98% lysine, 99% methionine, 99% threonine, antioxidant and special compound enzyme preparation for suckling pig in the premix into the V-type stainless steel mixer Mix evenly in the medium to obtain the initial mixture 2 for use;

[0073] Step 3: Put the initial mixture 1 and the initial mixture 2 obtained in step 1 and step 2 into the V-shaped stainless steel mixer together with multiple trace elements for suckling pigs, 1% zeolite powder and 50% choline chloride Mix evenly in the medium and obtain the premix for use;

[0074] Step 4: The national standard 1st grade corn, nat...

preparation Embodiment 2

[0114] Step 1: Weigh the ingredients according to the following formula:

[0115] National standard 1 grade corn 32%;

[0116] National standard 1 grade wheat 12%;

[0117] Extruded full-fat soybeans 13%;

[0118] Expanded dehulled soybean meal 5%;

[0119] Concentrated soy protein 8.4%;

[0120] 6% of defatted fish meal;

[0121] High protein whey powder 15%;

[0122] Consumption of glucose 2%;

[0123] High-quality soybean oil 2.1%;

[0124] Coconut oil 1%;

[0125] Calcium lactate 0.5%;

[0126] Feed grade calcium hydrogen phosphate 1%;

[0127] Premix 2%.

[0128] Among them, the formula of the premix is:

[0129] Multivitamins for suckling pig 0.04%;

[0130] Compound multiple trace elements for suckling pig 0.45%;

[0131] 50% choline chloride 0.1%;

[0132] 98% lysine 0.1;

[0133] 99% Methionine 0.1%;

[0134] 99% Threonine 0.06%;

[0135] Antioxidant 0.02%;

[0136] The special compound enzyme preparation for suckling pig 0.03%;

[0137] Sudafei 0.004%;

[0138] Antifoam sulfate 0.02%;

[0139] Ze...

preparation Embodiment 3

[0149] Step 1: Weigh the ingredients according to the following formula:

[0150] National standard 1 grade corn 32%;

[0151] National standard 1 grade wheat 10%;

[0152] Expanded full-fat soybeans 12%;

[0153] Puffed and dehulled soybean meal 8%;

[0154] Concentrated soy protein 8.0%;

[0155] 5% of defatted fish meal;

[0156] High protein whey powder 15%;

[0157] Consumption of glucose 2.5%;

[0158] High-quality soybean oil 2.1%;

[0159] Coconut oil 2%;

[0160] Calcium lactate 0.5%;

[0161] Feed grade calcium hydrogen phosphate 0.9%;

[0162] Premix 2%.

[0163] Among them, the formula of the premix is:

[0164] Multivitamins for suckling pig 0.04%;

[0165] Compound multiple trace elements for suckling pig 0.45%;

[0166] 50% choline chloride 0.1%;

[0167] 98% lysine 0.1;

[0168] 99% Methionine 0.1%;

[0169] 99% Threonine 0.06%;

[0170] Antioxidant 0.02%;

[0171] The special compound enzyme preparation for suckling pig 0.03%;

[0172] Sudafei 0.004%;

[0173] Antifoam sulfate 0.02%;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com