Wafer temperature detection method

A detection method and wafer technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of low temperature detection efficiency and inaccurate detection of wafer temperature, achieve good linear characteristics, improve accuracy, and increase application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the existing heating device for heating the wafer, the heat is transferred to the wafer through heat conduction or radiation, and when the temperature is detected, the stage or the processing chamber is generally controlled in a contact or non-contact manner. Therefore, the detected temperature is not necessarily the actual temperature inside the wafer. There is a difference between the detected temperature and the actual temperature, which is not conducive to the improvement of the performance of semiconductor devices and the establishment of related models. It takes a long time for temperature stabilization (generally more than 30 minutes) during heating to make the actual temperature in the wafer close to the set temperature of heating, which makes the whole measurement process take a long time and the efficiency is low.

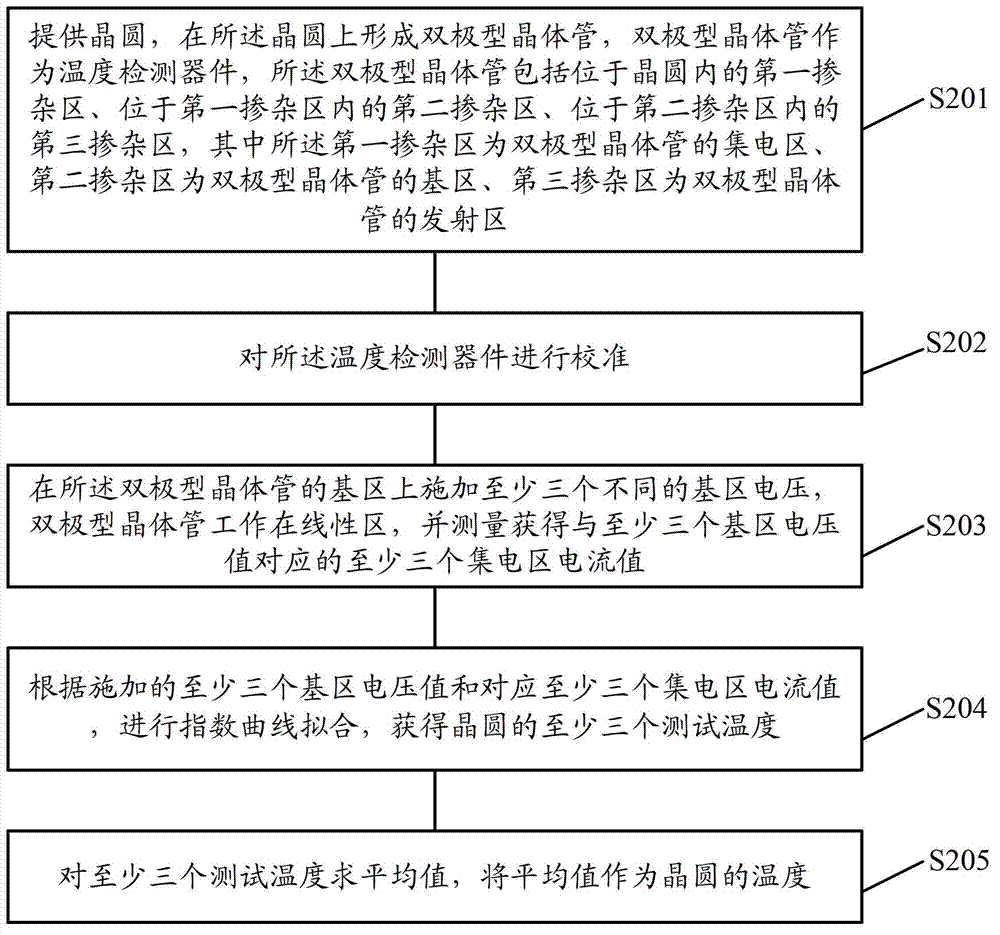

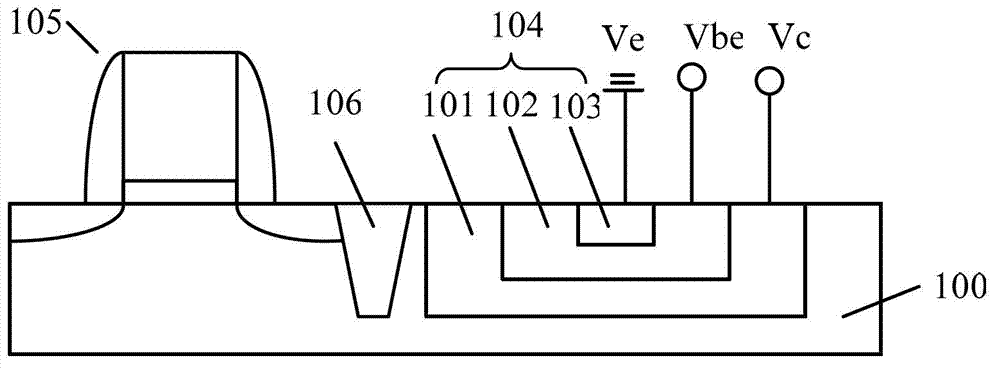

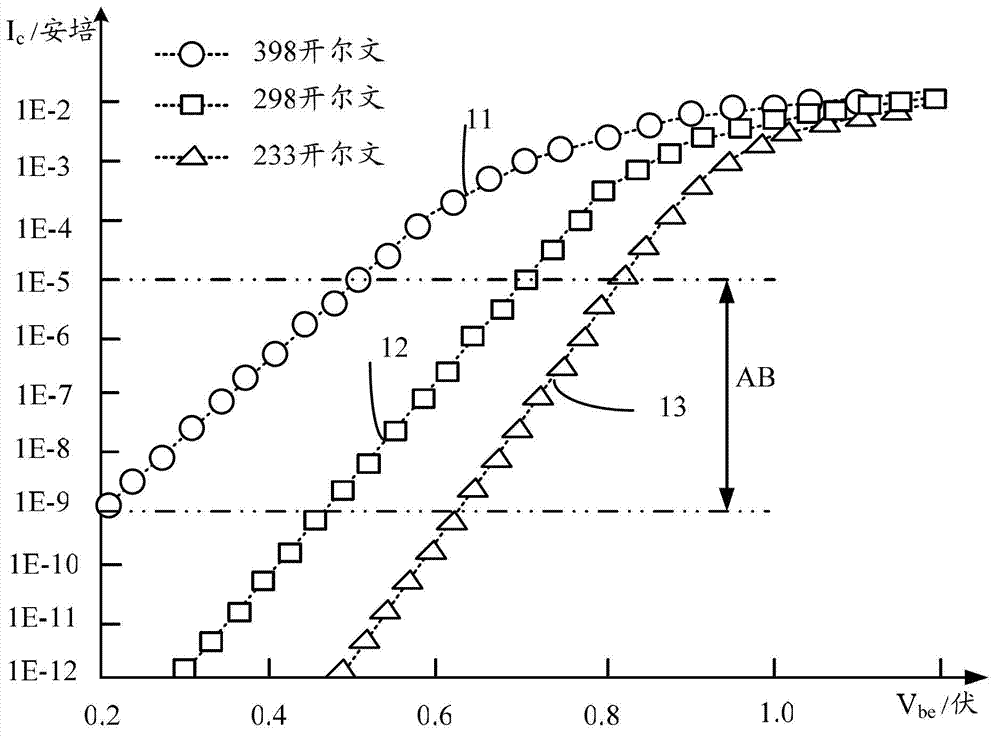

[0031] In order to solve the above problems, the inventor proposes a method for detecting the temperature of the wafer, forming a bipolar transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com