Printable graphene/ZnO-nano-composite-material-based temperature and humidity sensor electrodes

A nano-composite material, temperature sensor technology, applied in material capacitors, thermometers, analytical materials, etc., can solve the problems of reducing commodity value, withering of fruits and vegetables, etc., and achieve the effect of good response recovery time and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for making a printable graphene / ZnO nanocomposite microarray temperature sensor electrode is as follows:

[0027] 1) Doping graphene with nano-ZnO. Take 10mg of graphene powder and disperse it into 100ml of dimethylformamide (DMF), ultrasonic treatment for 1h, the ultrasonic equipment adopts KQ-100DV CNC ultrasonic cleaner, then adjust the viscosity of EC-GNP solution by adding ethylene glycol and glycerin, and continue ultrasonication 1h, the solvent ratio is DMF: ethylene glycol: glycerol=50:45:5 vol%, obtains graphene conductive ink; Then 0.02g nano ZnO powder is added in this solution ultrasonic dispersion 1h, obtains graphene / ZnO nanocomposite Material conductive ink.

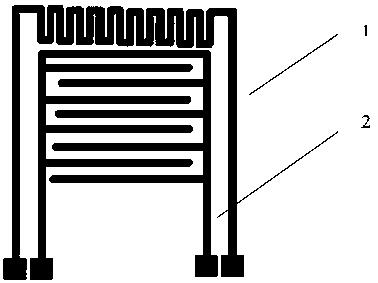

[0028] 2) Use graphene / ZnO nanocomposite conductive ink to print serpentine electrodes, and repeat printing 20 times to obtain printed electrodes. In the RTA rapid thermal annealing system, N 2 Under a protective atmosphere, anneal at 300°C for 300s to obtain printed electrodes for tempe...

Embodiment 2

[0033] Embodiment 2 Temperature and humidity sensor test results

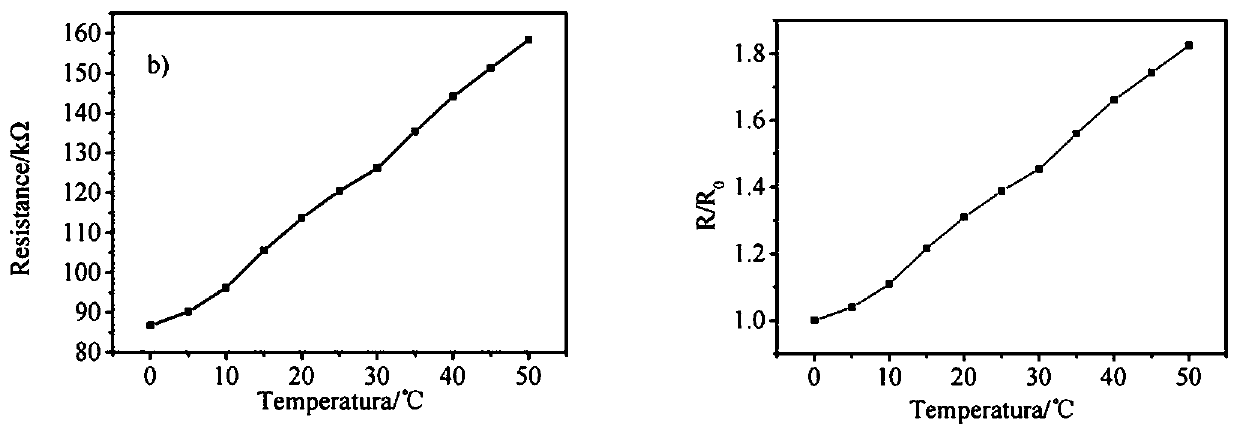

[0034] In the present invention, the resistance value of the temperature sensor varies with temperature and its linearity is as follows: image 3 Shown; temperature sensor repeatability and stability as Figure 4 shown. The capacitance value of the humidity sensor varies with the humidity curve as shown in Figure 5 Shown; humidity sensor hysteresis and response recovery time as Image 6 Shown; humidity sensor repeatability and stability as Figure 7 shown.

[0035] It can be seen from the figure that the temperature sensor shows good linearity, the sensitivity is 1.6% Ω / ℃, the linearity and correlation factor are 2.0% and 0.995, respectively, and the repeatability and stability are good. The humidity sensor has a sensitivity of 6.568nF / RH% in a high-humidity environment and a hysteresis of 5.19%. It has good response recovery time and repeat stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com